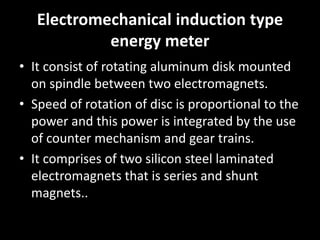

Electric meters measure the amount of electric energy consumed. There are two main types - electromechanical induction meters and electronic meters. Electromechanical meters use rotating disks and electromagnets to measure power integrated over time into kilowatt-hours. Electronic meters use digital microchips to sample voltage and current and convert this into pulses representing kilowatt-hours. Meters must be mounted in accessible locations according to safety standards to allow for reading and maintenance.

![USE

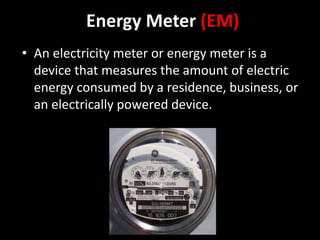

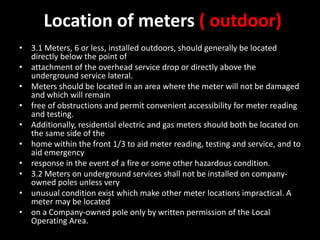

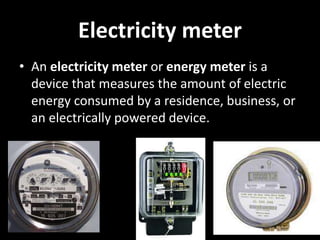

• Electric utilities use electric meters installed at

customers' premises to measure electric energy

delivered to their customers for billing purposes.

They are typically calibrated in billing units, the

most common one being the kilowatt hour

[kWh]. They are usually read once each billing

period.

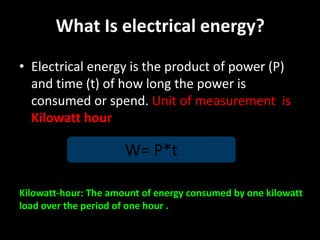

• The most common unit of measurement on the

electricity meter is the kilowatt hour [kWh]](https://image.slidesharecdn.com/electricitymeter145-170308185145/85/Electricity-meter-4-320.jpg)