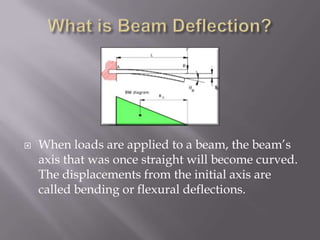

The document outlines an experiment to investigate how aluminum and brass beams deflect under various applied loads, utilizing a cantilever beam setup. The goals include calculating Young’s modulus based on measured deflections and comparing it with tabulated values, with results indicating higher than expected deflections and an error margin of 10-20%. The structure and analysis, including MATLAB code for deflection calculations, are detailed alongside initial results and conclusions regarding the mechanical properties of the materials tested.