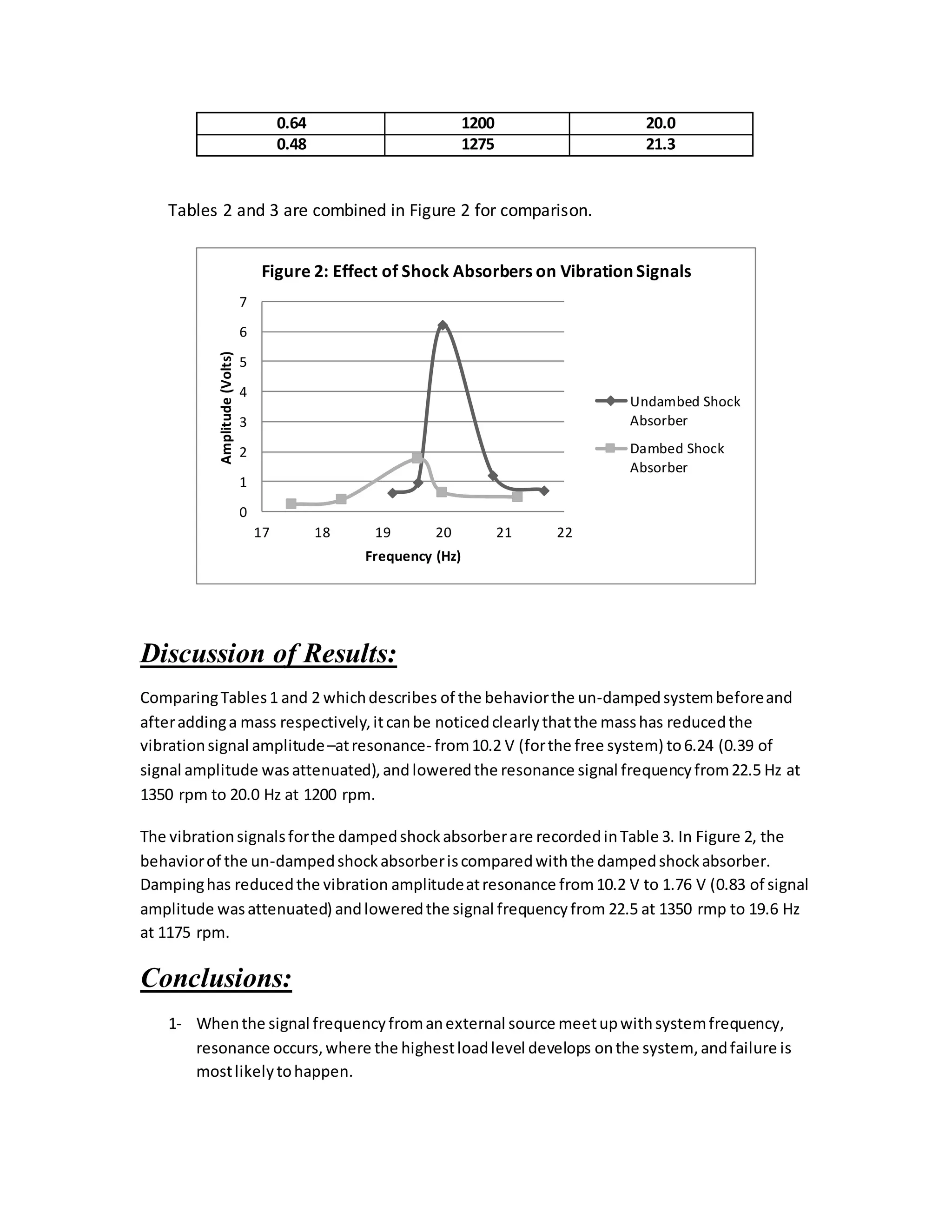

This document outlines an experiment on lateral beam vibration, comparing un-damped and damped shock absorbers. The study finds that adding mass to the un-damped system reduces signal amplitude and lowers resonance frequency, while the damped absorber is more effective, significantly attenuating vibration signals. Results demonstrate that resonance leads to increased load levels, highlighting the importance of vibration control in engineering applications.