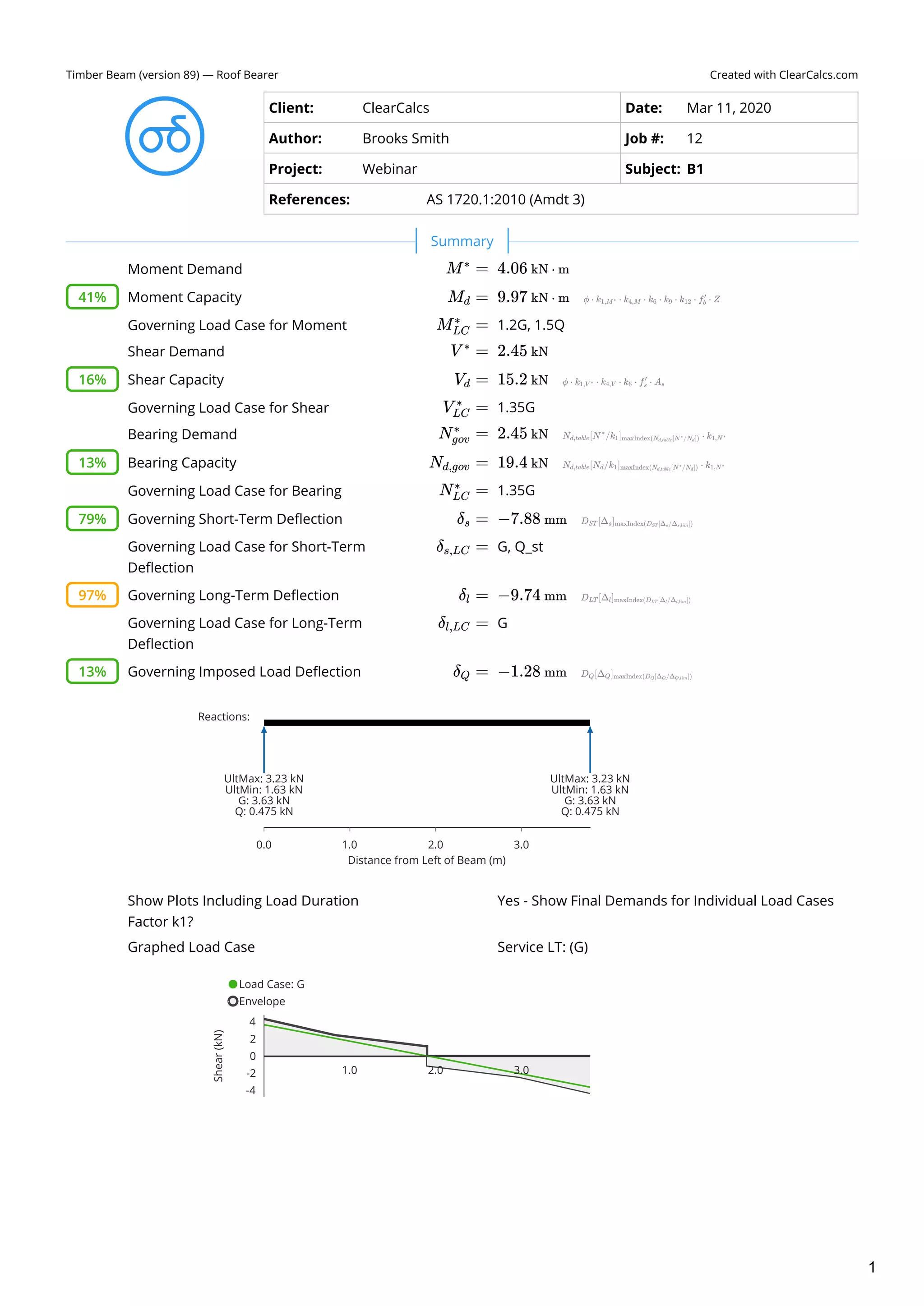

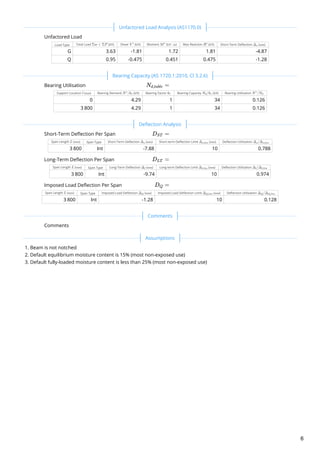

This document analyzes a timber beam used as a floor bearer. It summarizes the demands on the beam from different load cases, including moment, shear, bearing and deflection. The governing load cases are identified as 1.2G, 1.5Q for moment, shear and bearing demands. Short-term deflection is governed by load case G, Q_st, while long-term deflection is governed by G, Q_lt. The beam properties, load cases, demands and capacities are analyzed according to AS1720.1:2010 timber design standard.