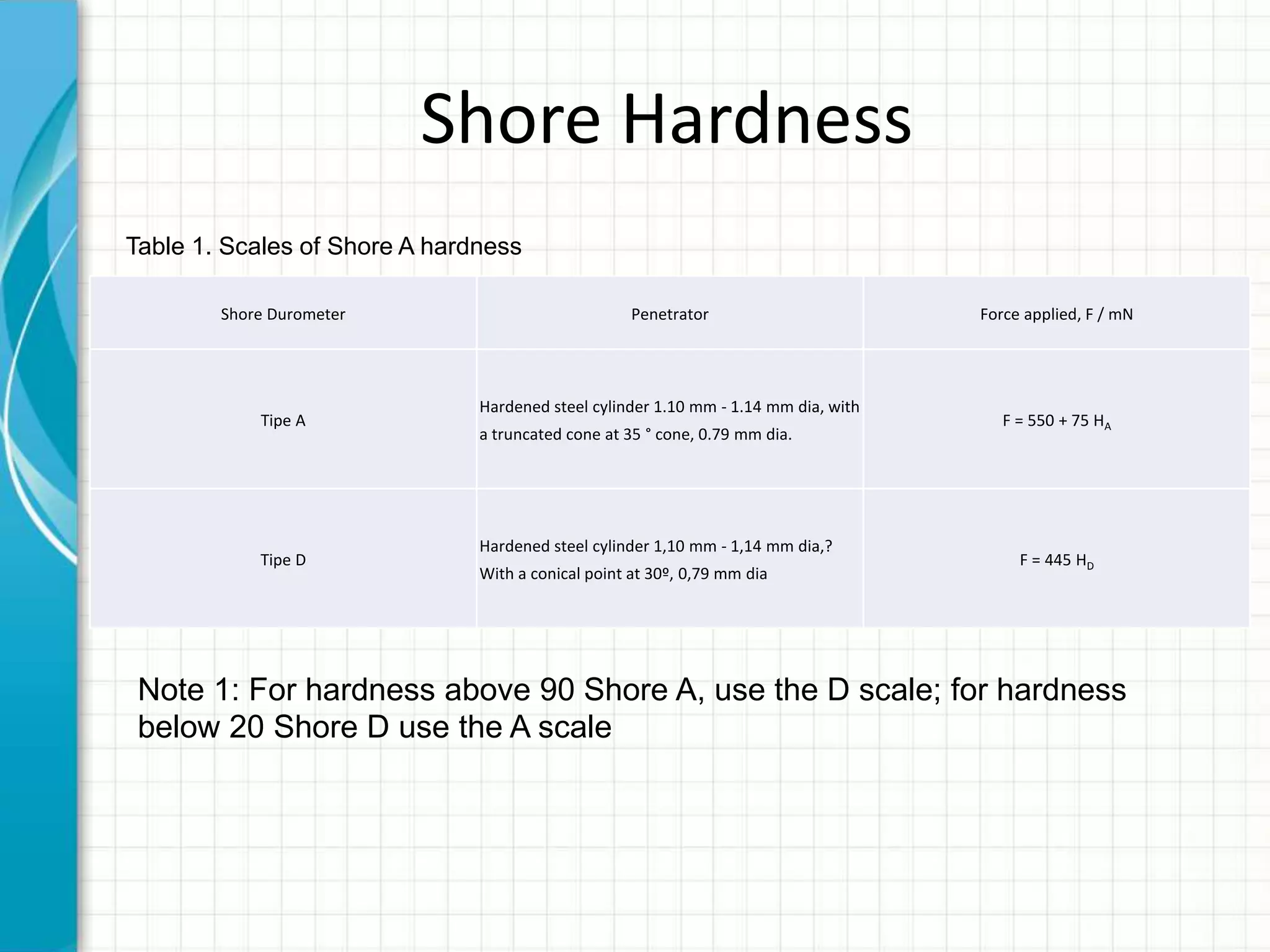

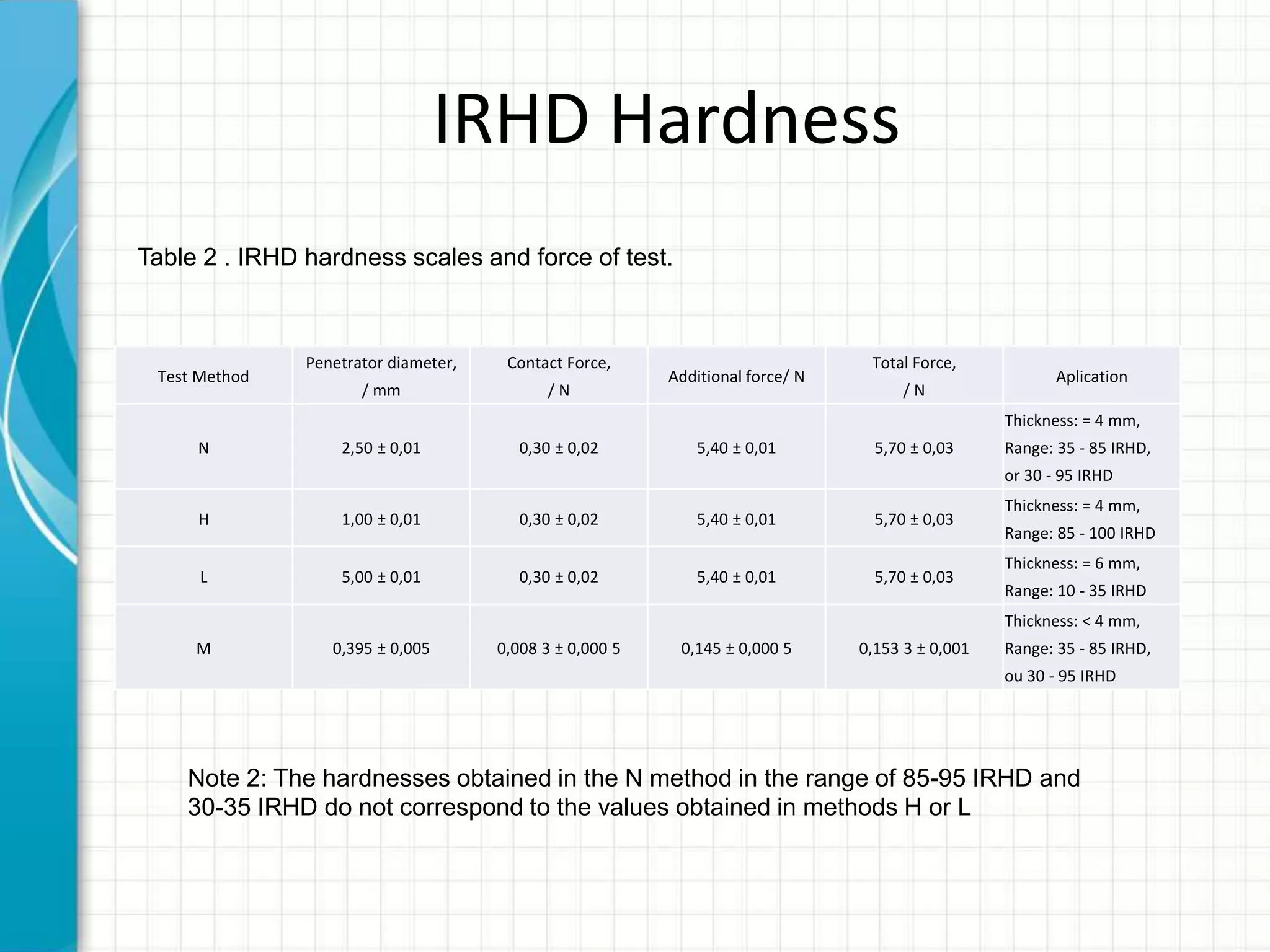

This document discusses methods for measuring the hardness of rubber compounds. It describes the Shore hardness and IRHD hardness scales. The Shore hardness scale uses a penetrator that is pressed into the material, with hardness inversely proportional to penetration depth. There are type A and D scales using different penetrators and forces. The IRHD scale also measures penetration depth but uses different penetrator sizes and forces depending on the expected hardness range. Both provide a standardized way to accurately measure and compare rubber hardness.