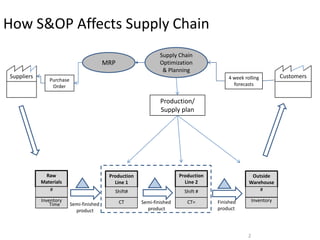

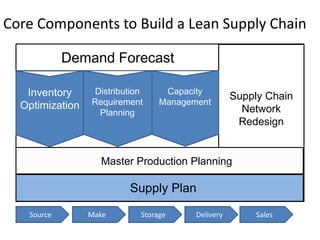

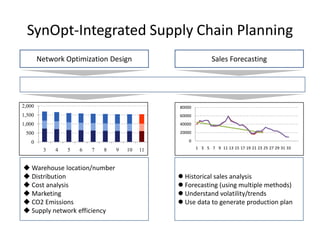

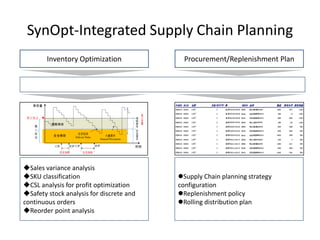

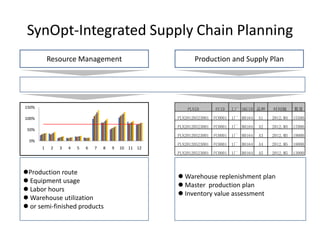

The document discusses building an integrated supply chain planning platform. It describes how the platform integrates demand forecasting, inventory optimization, distribution planning, capacity management, and resource management to generate production and supply plans. The platform uses sales data, inventory levels, production capabilities, and other factors to optimize the supply chain network and inventory levels and generate rolling forecasts and replenishment plans. The integrated approach aims to provide an efficient, optimized supply chain.