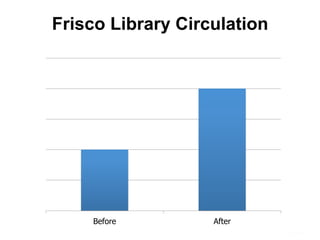

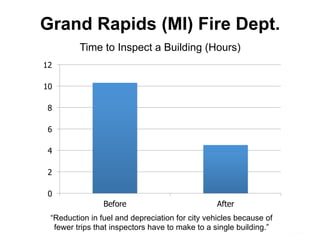

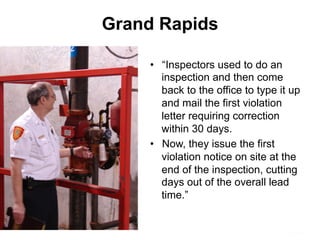

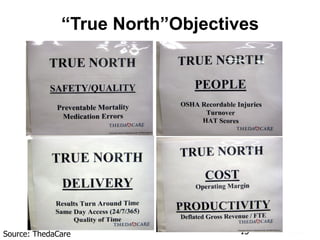

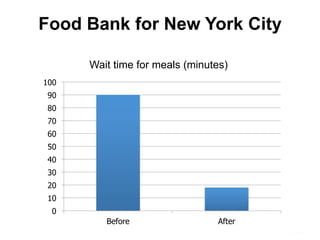

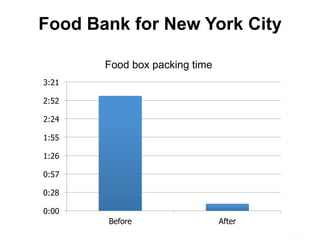

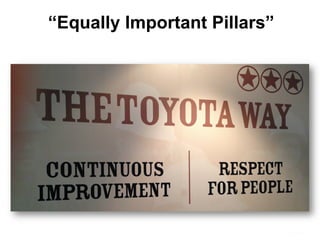

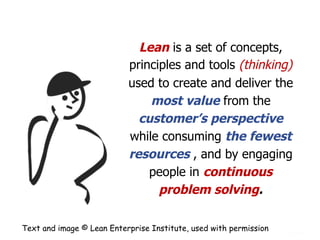

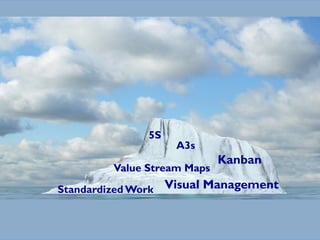

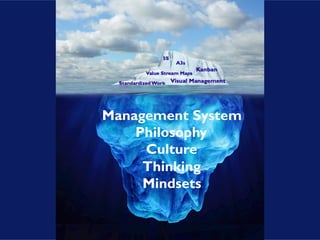

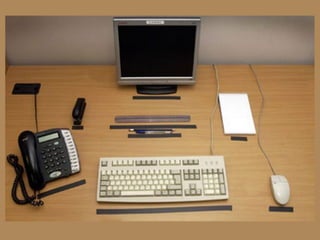

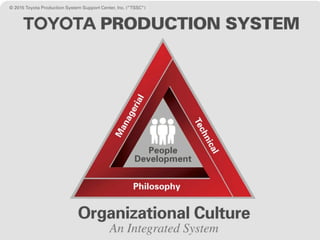

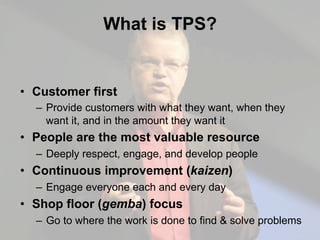

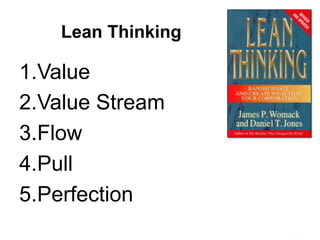

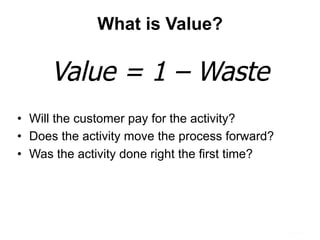

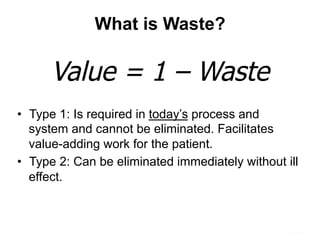

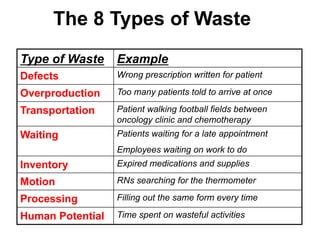

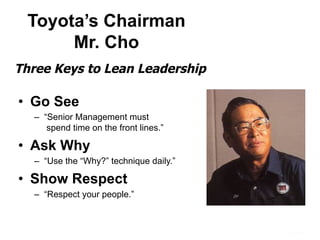

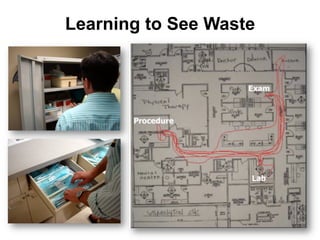

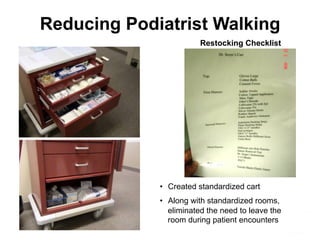

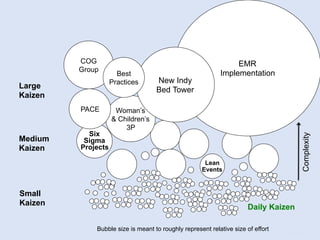

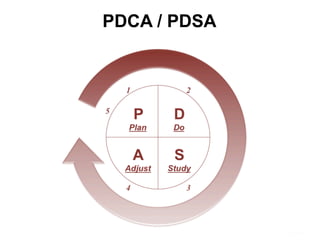

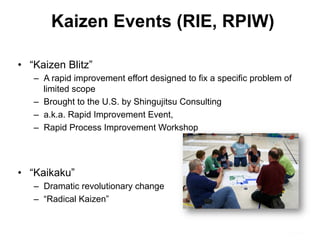

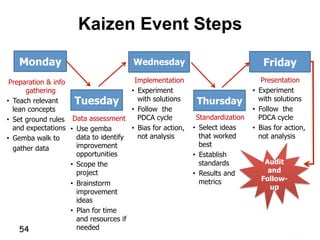

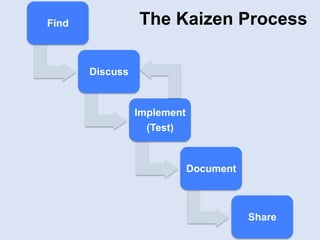

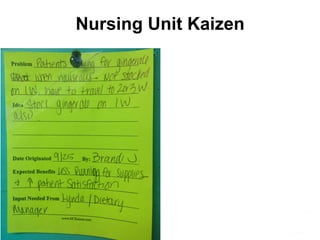

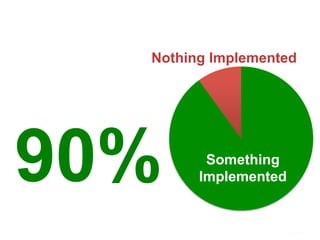

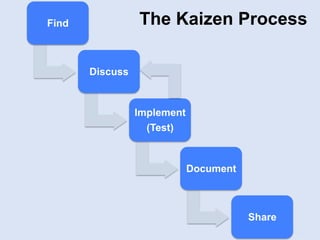

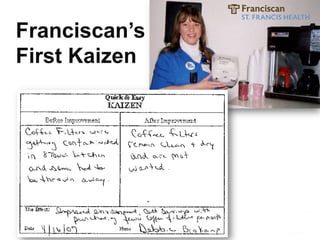

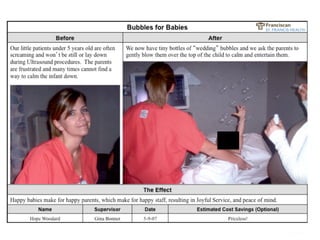

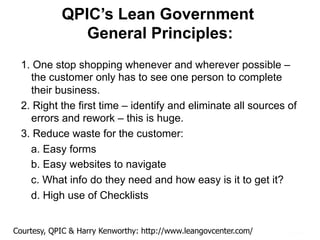

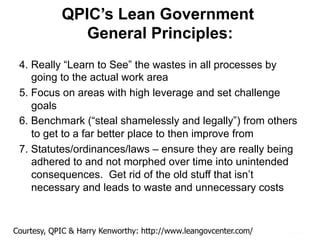

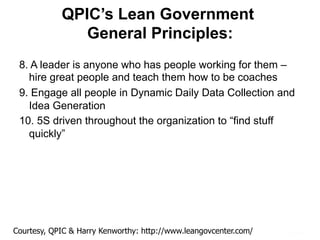

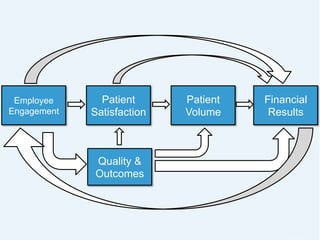

Lean is a set of concepts and tools used to maximize value and minimize waste from the customer's perspective. It involves engaging employees in continuous improvement. Examples show how lean helped improve processes in healthcare, manufacturing, and government. Key lean principles include specifying value, mapping the value stream, creating flow, establishing pull, and seeking perfection. Continuous improvement involves small, incremental tests of changes through the Plan-Do-Check-Act cycle.