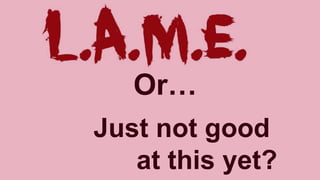

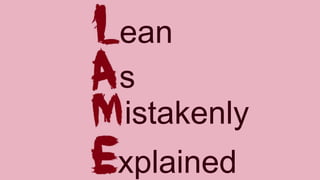

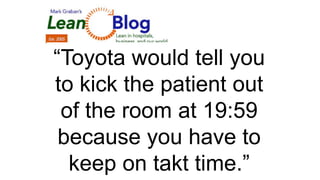

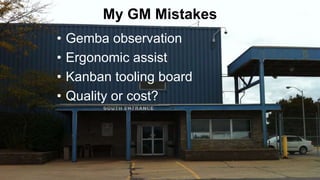

This document discusses the speaker's reflections on 20 years of trying to implement and practice Lean in manufacturing and healthcare settings. It shares many of the mistakes and lessons learned during that time, including implementing the wrong tools for the culture, not sustaining gains from improvement efforts, and not adopting a continuous improvement mindset. The goal is to encourage others learning Lean by sharing these experiences in order to help people avoid similar pitfalls and get better at continuously improving.

![“Lean will help you to reduce or

eliminate [wastes] 1 through 6.

Six Sigma will help you to

reduce number 7 [defects].”](https://image.slidesharecdn.com/practicinglean2016leanfrontiers16x9share-160424140251/85/Mark-Graban-Practicing-Lean-Lean-Frontiers-TWI-HR-Summit-May-2016-61-320.jpg)

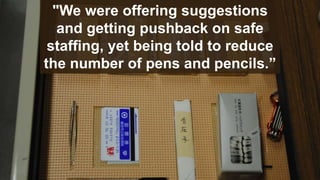

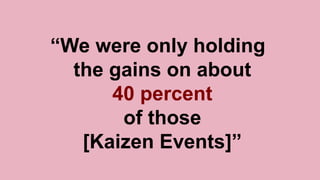

![“We were only holding

the gains on about

40 percent

of those

[Kaizen Events]”](https://image.slidesharecdn.com/practicinglean2016leanfrontiers16x9share-160424140251/85/Mark-Graban-Practicing-Lean-Lean-Frontiers-TWI-HR-Summit-May-2016-72-320.jpg)