Using Quality Improvement Tools to Deliver Better Health care

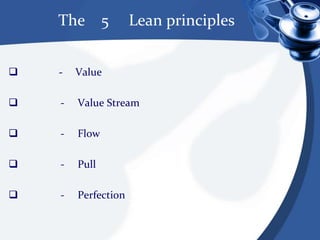

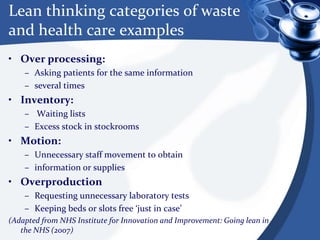

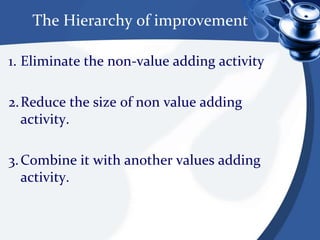

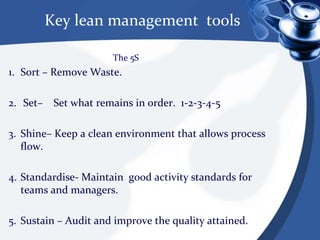

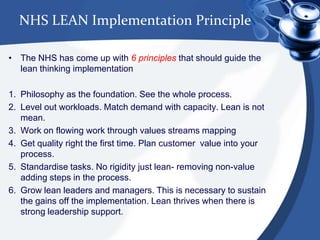

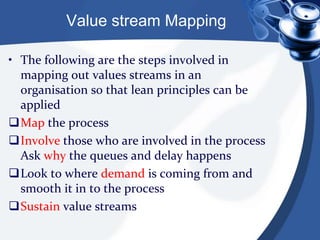

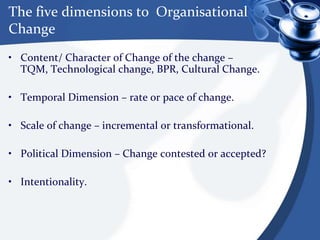

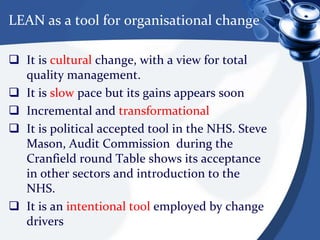

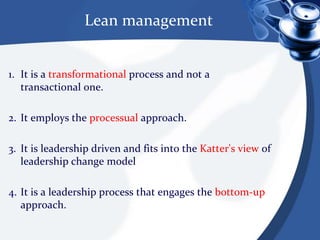

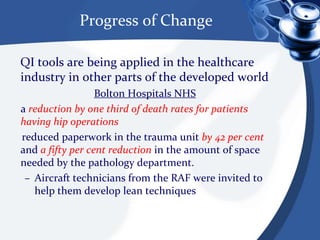

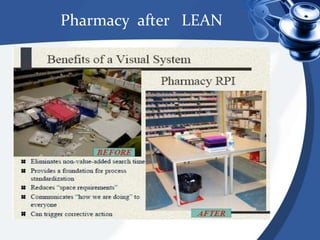

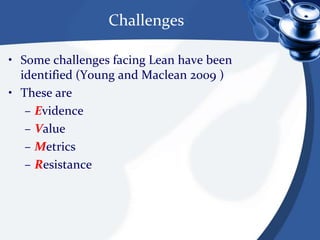

Quality improvement tools like Lean principles aim to continuously improve healthcare quality by engaging all stakeholders to eliminate waste. Lean was introduced to healthcare in the 1990s from other industries and focuses on optimizing value streams to reduce errors, waiting times, and unnecessary processes. The NHS has implemented Lean thinking through tools like 5S, value stream mapping, and by developing lean leaders. While challenges remain around evidence, metrics, and resistance to change, Lean implementation in hospitals like Royal Bolton has significantly reduced waste, space needs and processing times, showing potential for improving healthcare delivery when fully adopted.