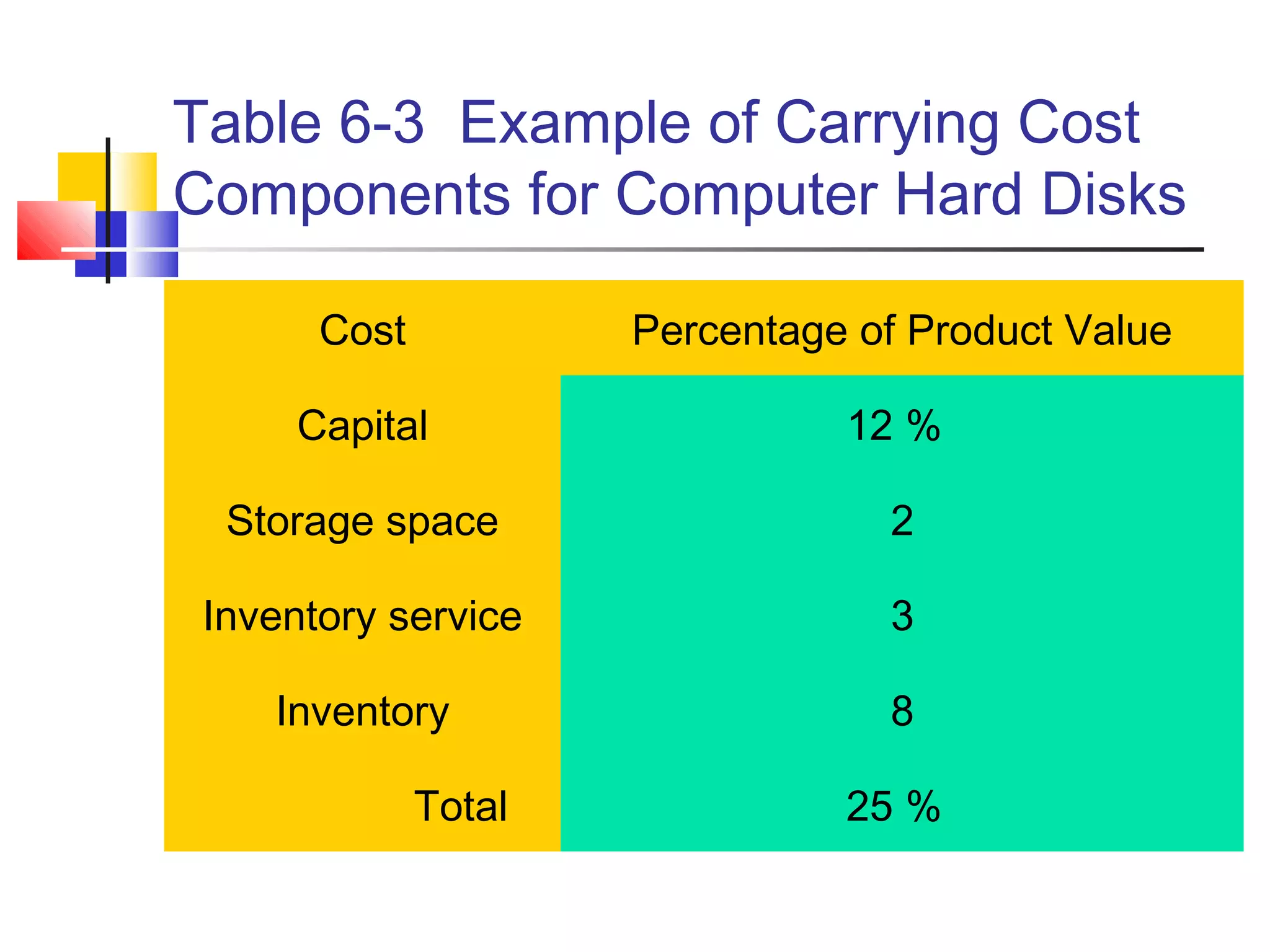

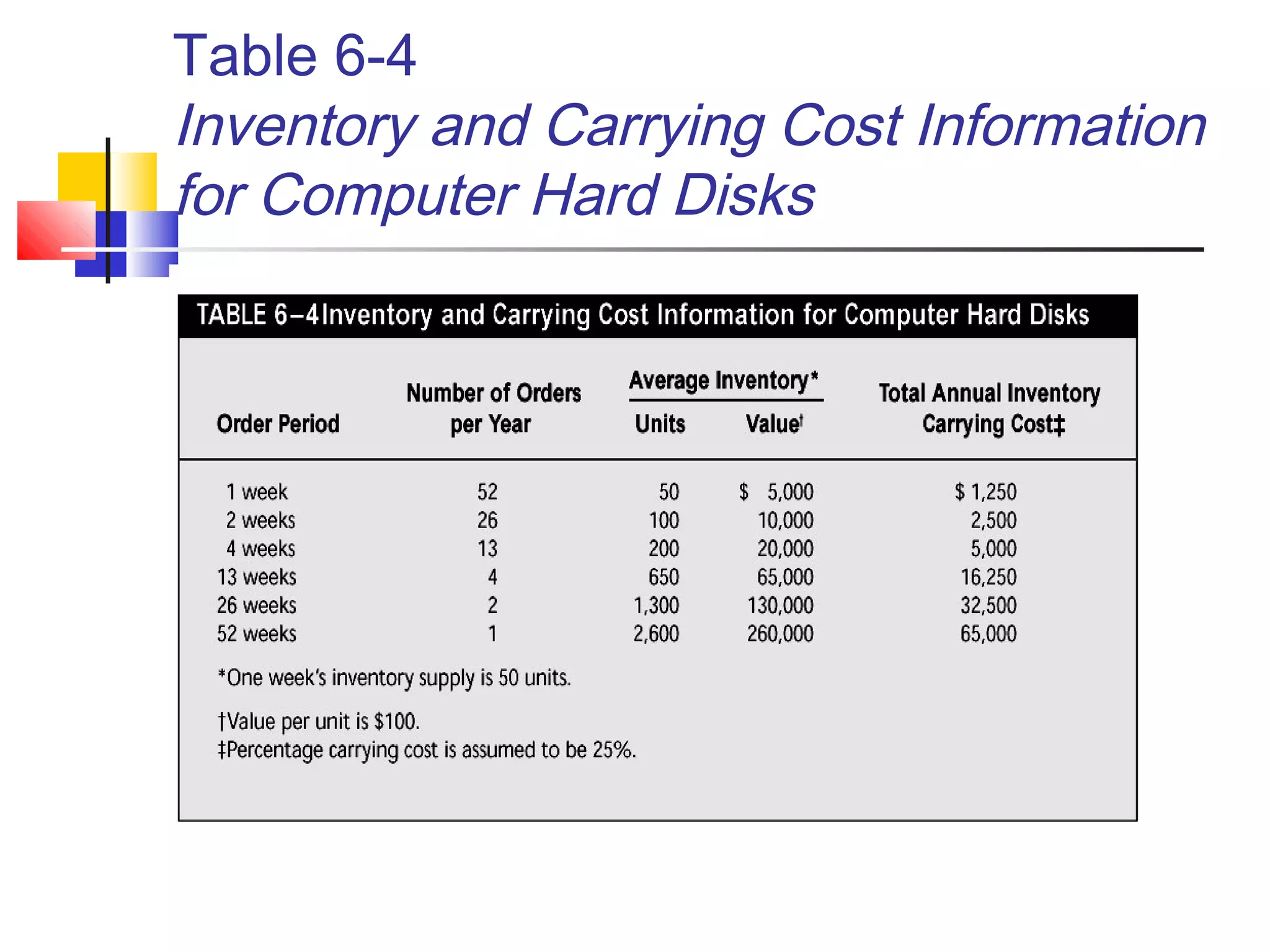

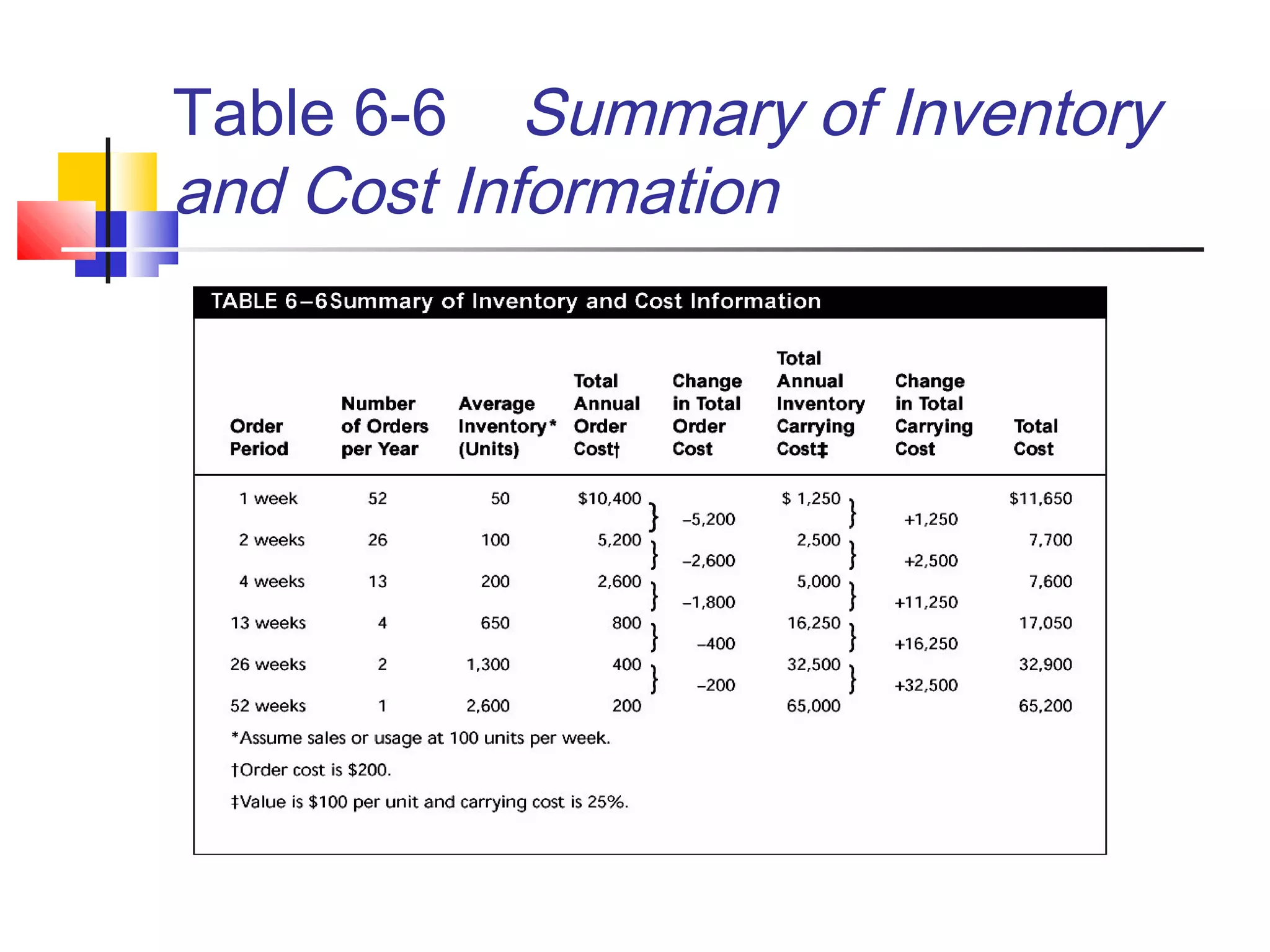

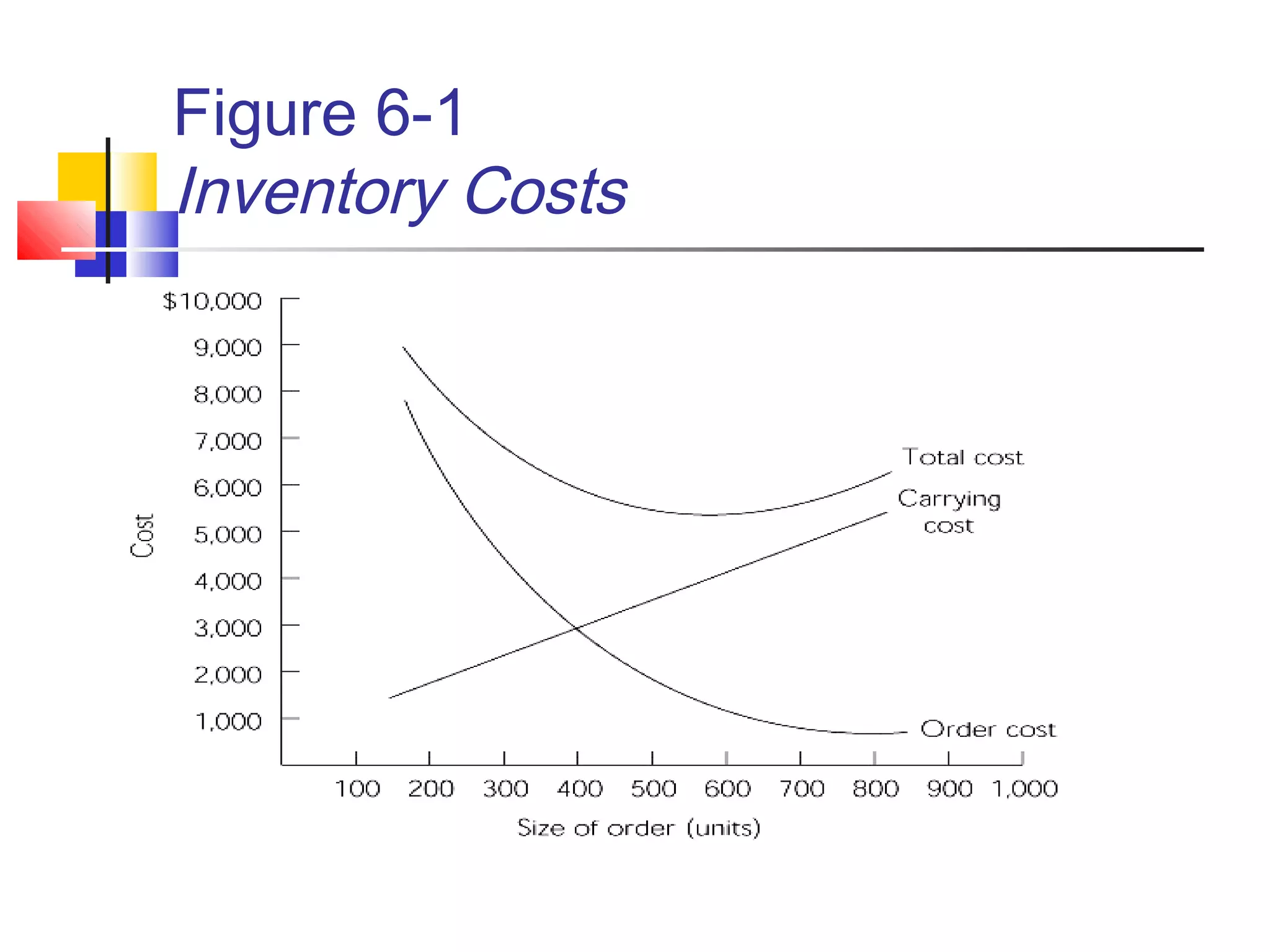

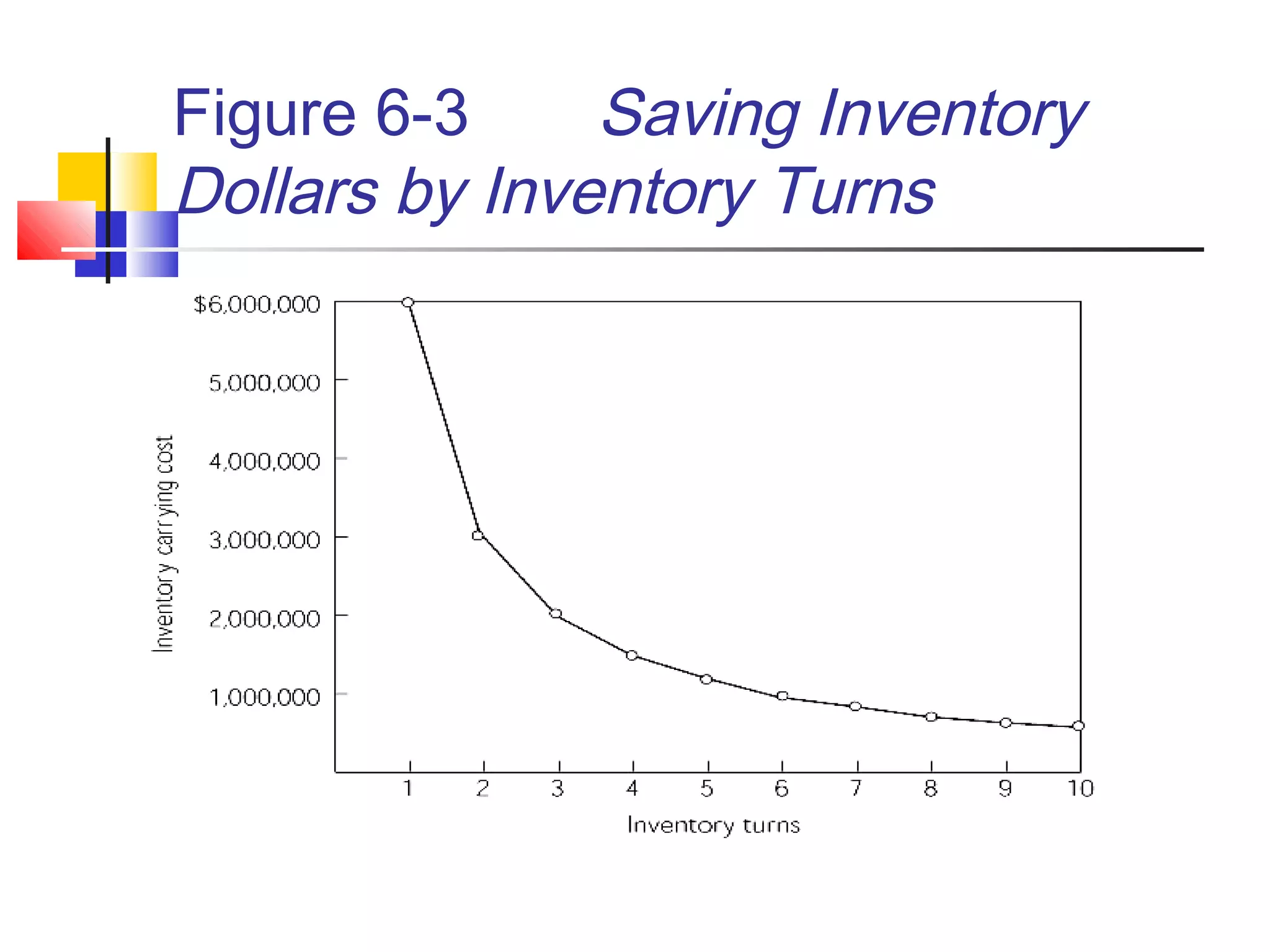

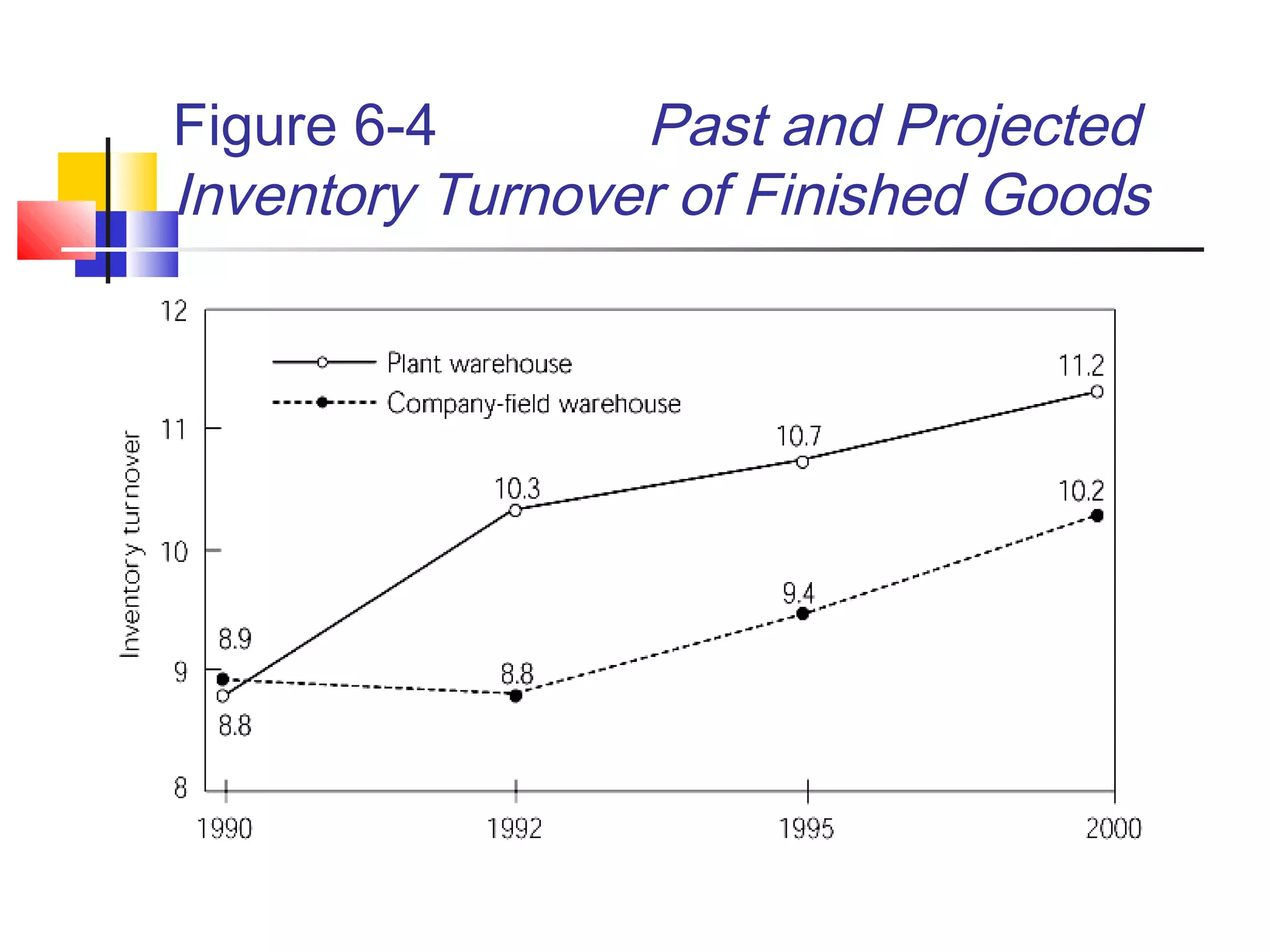

This chapter discusses the importance of managing inventory flows throughout the supply chain. It covers the reasons companies hold inventory, including batching economies, uncertainty/safety stocks, and seasonality. It also discusses the major costs of inventory, including carrying costs, order/setup costs, and stockout costs. The chapter introduces ABC analysis for classifying inventory items and explains how inventory visibility throughout the supply chain can benefit companies. It provides methods for evaluating inventory management effectiveness, such as calculating inventory turnover ratios.