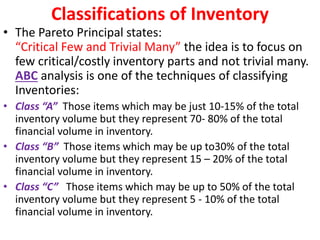

The document discusses inventory management. It describes the functions of inventory management as decoupling production from suppliers, providing selection for customers, taking advantage of quantity discounts, and hedging against price changes. It also describes different types of inventory like raw materials, work in process, and finished goods. A key concept is ABC analysis for classifying inventory into classes A, B, and C based on financial value and controlling inventory accordingly. Record accuracy is important for making precise reorder and scheduling decisions. The document also compares periodic and continuous inventory review systems.