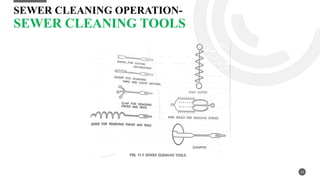

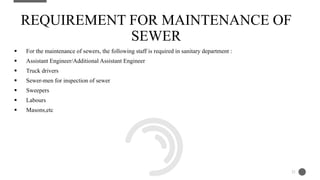

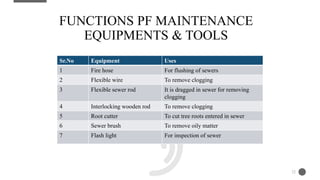

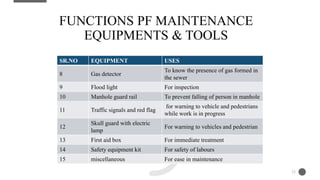

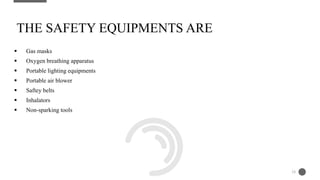

This document discusses procedures and safety measures for sewer maintenance. It covers causes of sewer troubles like clogging, breakage, and odors. Methods of sewer cleaning like flushing, tools, and inspection are described. Requirements for maintenance like staff, equipment, and tools are outlined. Functions and selection of maintenance equipment and tools are covered. Hazards like explosions in sewers and safety precautions are also summarized.