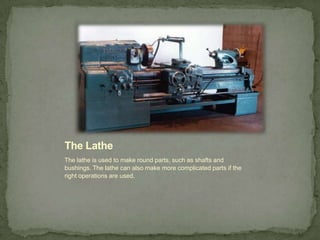

The document discusses several types of machine tools used in manufacturing. The lathe is used to make round parts like shafts and bushings. The vertical milling machine mills flat surfaces and grooves and can cut keyways or flats on shafts. The horizontal milling machine has been replaced by the vertical milling machine but can also produce gears. The drill press drills holes while the radial arm drill press drills large workpieces. The surface grinder provides extremely precise flat surfaces within 0.0001 inches. CNC machines are computer-controlled and faster than manual machines. The turning center is a CNC lathe while the machining center is a CNC milling machine.