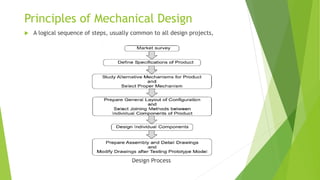

This document provides an introduction to machine design. It defines machine design as using scientific principles, technical information, and imagination to describe a machine to perform specific functions with maximum economy and efficiency. The document then outlines the basic principles of mechanical design, including the design process and considerations for static and fatigue loads. It also discusses standards and material selection in machine design.