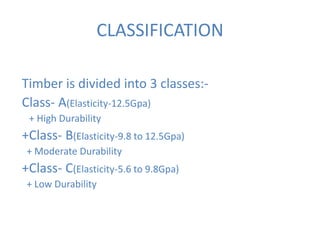

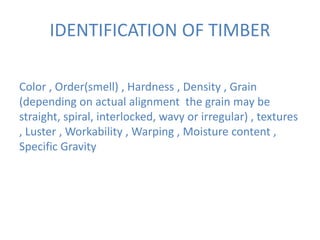

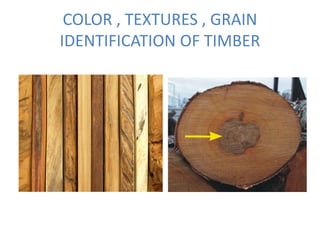

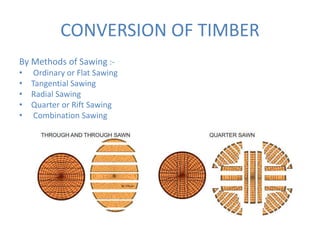

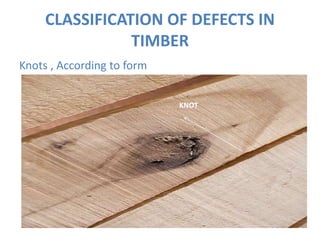

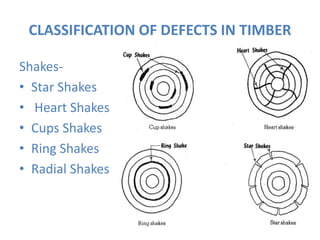

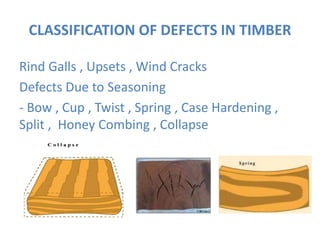

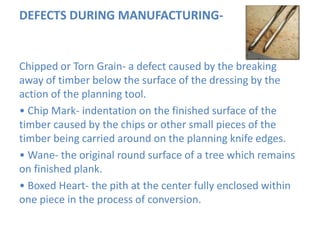

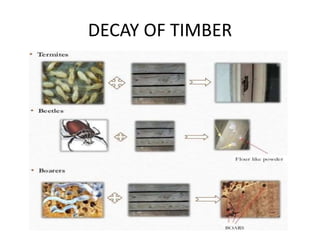

Timber refers to wood that can be used for construction, whether standing as trees or cut into boards. It is classified into three classes based on elasticity and durability. Timber is identified by features like color, grain, texture, and moisture content. It can be converted through various sawing methods. Timber defects include knots, shakes, cracks, and defects from seasoning or manufacturing. Proper treatment and prevention methods can increase timber's durability and lifespan.