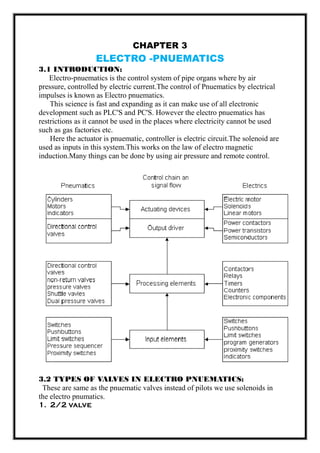

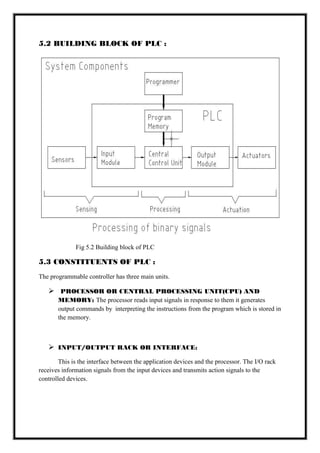

The document is a summer internship report submitted by Sai Shubhankar for an internship at Central Institute of Tool & Design in Hyderabad, India. It discusses a project on automatic feeding, measuring temperature, and ejecting components using a programmable logic controller (PLC). The report includes training received on mechatronics topics like automation, pneumatics, electro-pneumatics, sensors, and PLCs. It also provides details of the internship project which used a PLC to control temperature measurement and sorting of components based on sensor inputs.