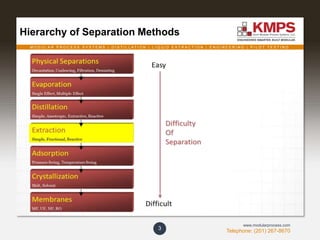

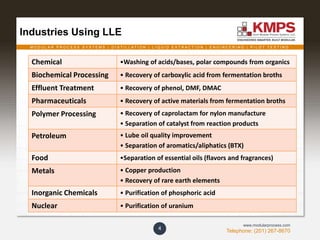

The document discusses the advantages and applications of liquid-liquid extraction (LLE) as a separation method, particularly when distillation is not feasible. It highlights challenges engineers face in adopting LLE technology and presents KMPS as a leader in LLE solutions, detailing their extensive experience and services in optimizing extraction processes. Several case studies demonstrate successful LLE implementations across various industries, showcasing KMPS's ability to design and supply effective extraction systems.