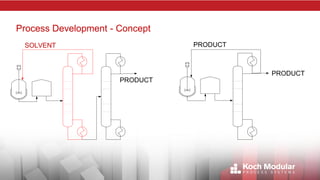

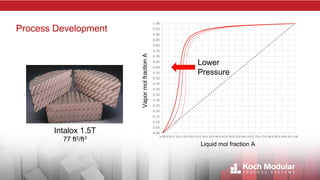

The document discusses the process of moving from concept to commercialization in the chemical processing industry, emphasizing the challenges of process development and scale-up. It presents Koch Modular Process Systems, highlighting its expertise in modular construction and engineering solutions for various sectors. Additionally, the document includes case studies showcasing successful projects in recycled polypropylene and biomass conversion, demonstrating the efficacy of Koch Modular's approach.