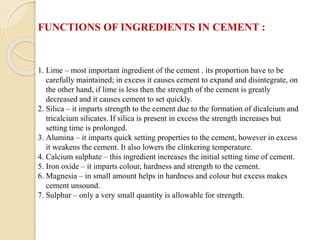

Limestone is a sedimentary rock made up of shells of dead sea creatures that built up over millions of years. Limestone can be soft like chalk, comparatively hard like limestone, or hardest like marble. Lime mortar is made by mixing lime and sand or surkhi with water. It is used for above ground construction and has lower strength and water resistance than cement mortar. Lime has various uses including in masonry mortars, plaster, whitewash, and production of masonry blocks. Cement is made by crushing limestone and other materials, mixing them in wet or dry processes, grinding, burning at high temperatures to form clinkers, and further grinding. The ingredients and their proportions