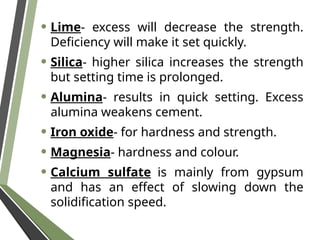

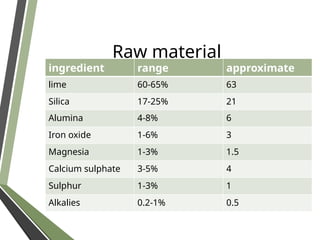

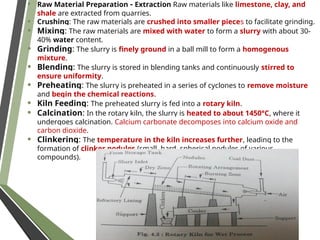

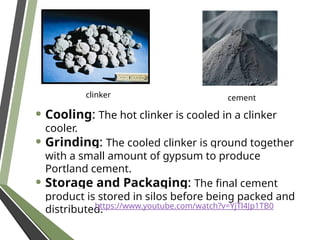

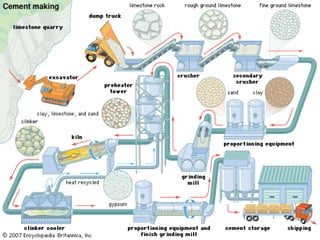

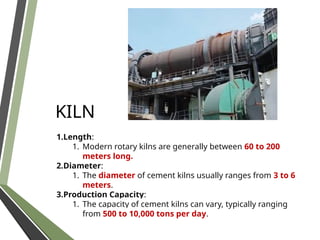

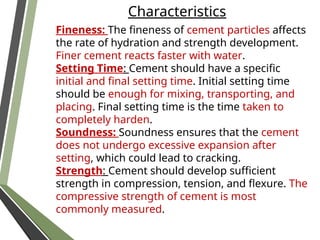

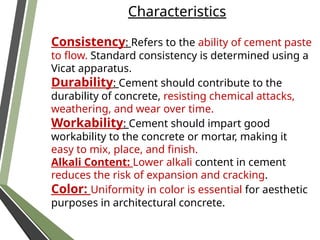

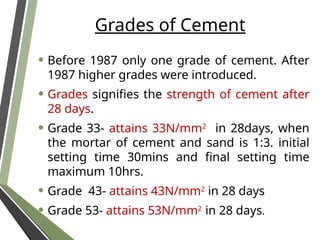

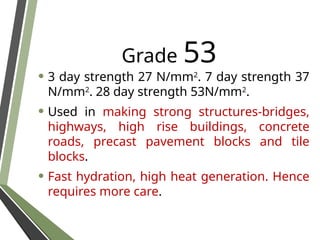

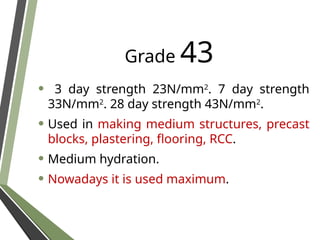

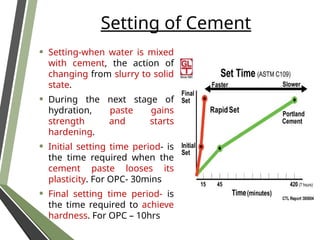

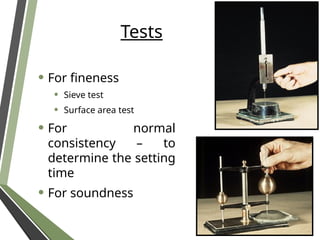

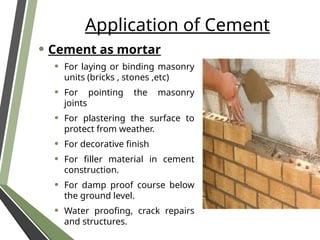

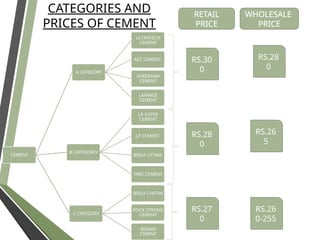

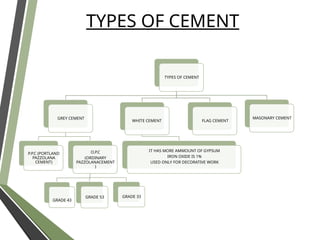

The document provides a comprehensive overview of cement, including its raw materials, manufacturing processes, characteristics, types, and uses. Key details include the steps in cement production from raw material preparation to grinding and packaging, as well as the various types of cement and their specific properties and applications. It also discusses grades of cement, their strengths, and appropriate storage guidelines.