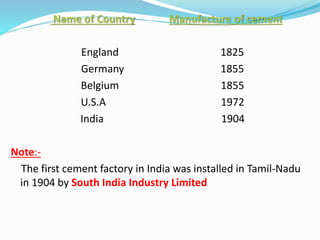

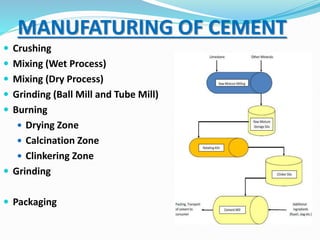

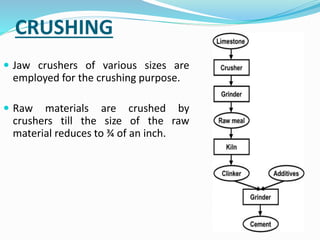

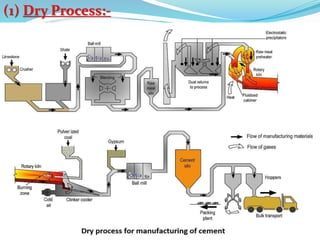

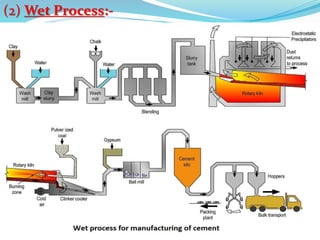

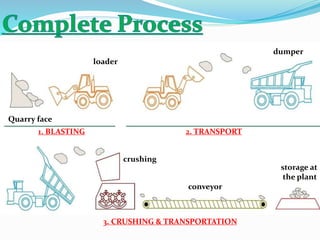

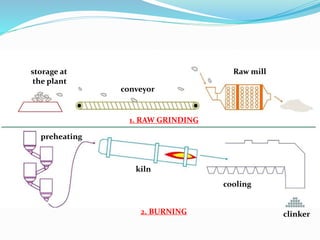

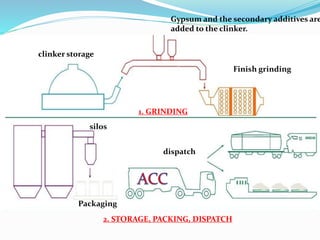

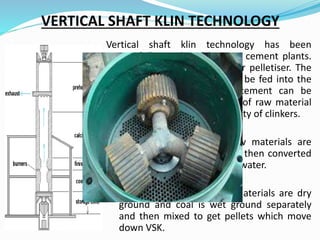

Cement is produced through a process involving crushing, grinding, and burning of limestone and clay. Joseph Aspdin first produced Portland cement in 1824. The first cement factory in India was established in Tamil Nadu in 1904. Cement production involves quarrying raw materials, crushing them, mixing with water or dry process, grinding, burning at high temperatures to form clinker, cooling clinker, and final grinding with gypsum. Cement is used widely in construction activities like building, roads, bridges due to its binding properties and high compressive strength.