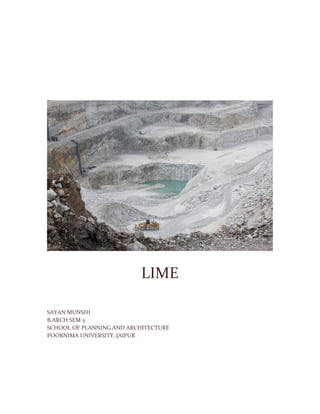

Lime, derived from limestone, has been widely used in construction for its properties such as workability, breathability, and ecological benefits. Historically significant, lime has been a staple building material in various cultures, particularly in the Indian sub-continent since ancient times. Its unique characteristics not only enhance the durability and aesthetic of structures but also contribute to healthier living environments.