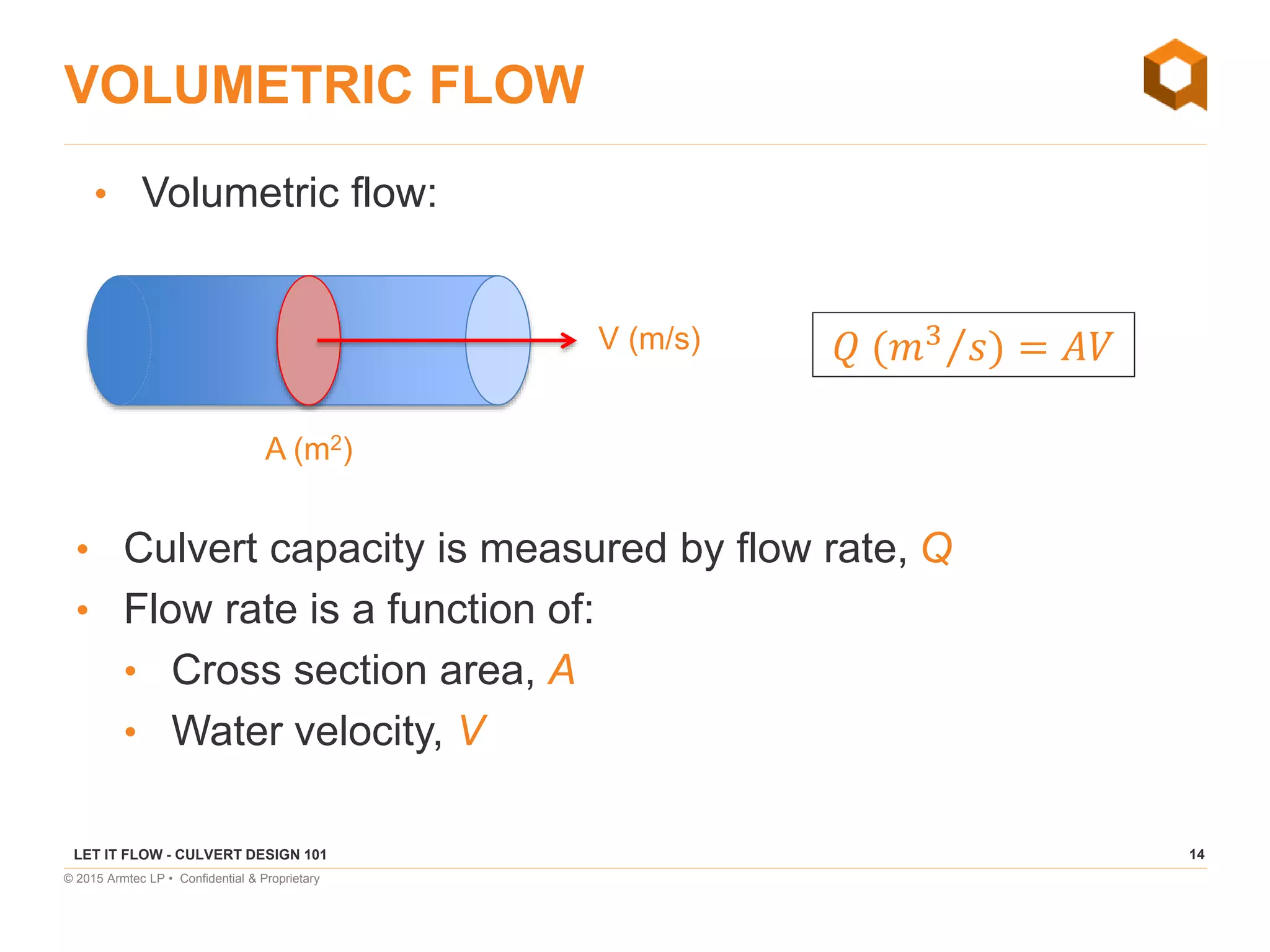

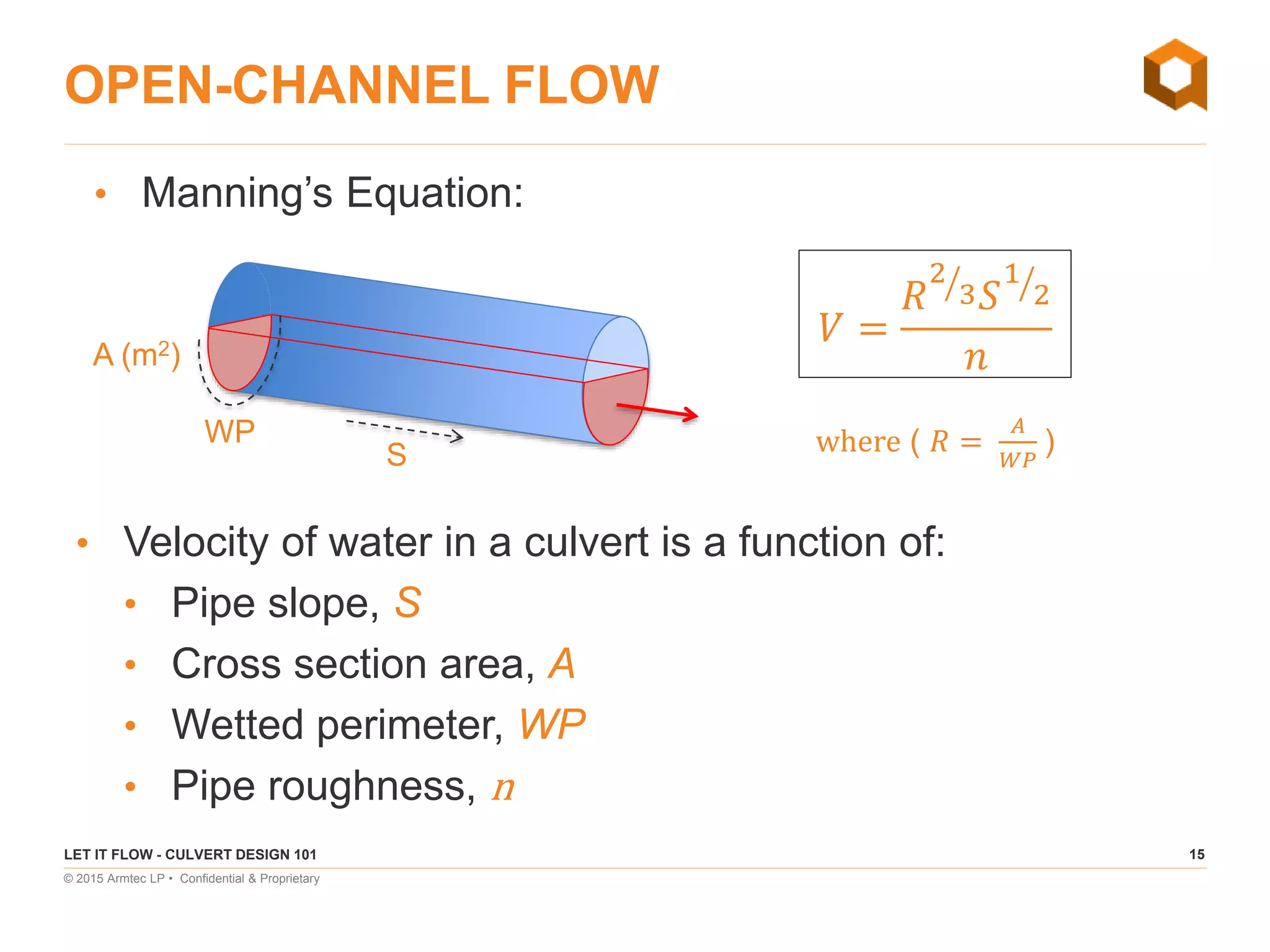

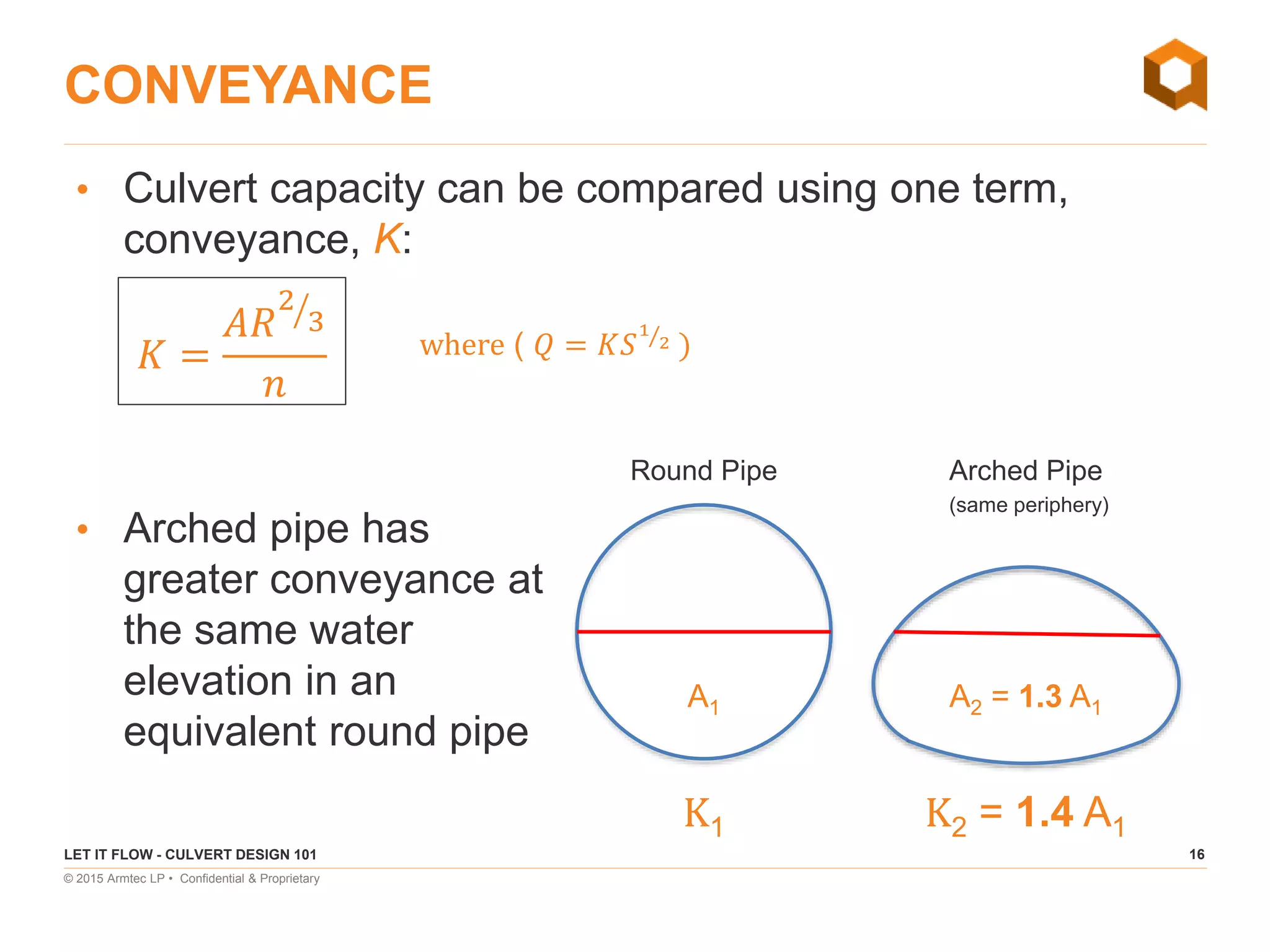

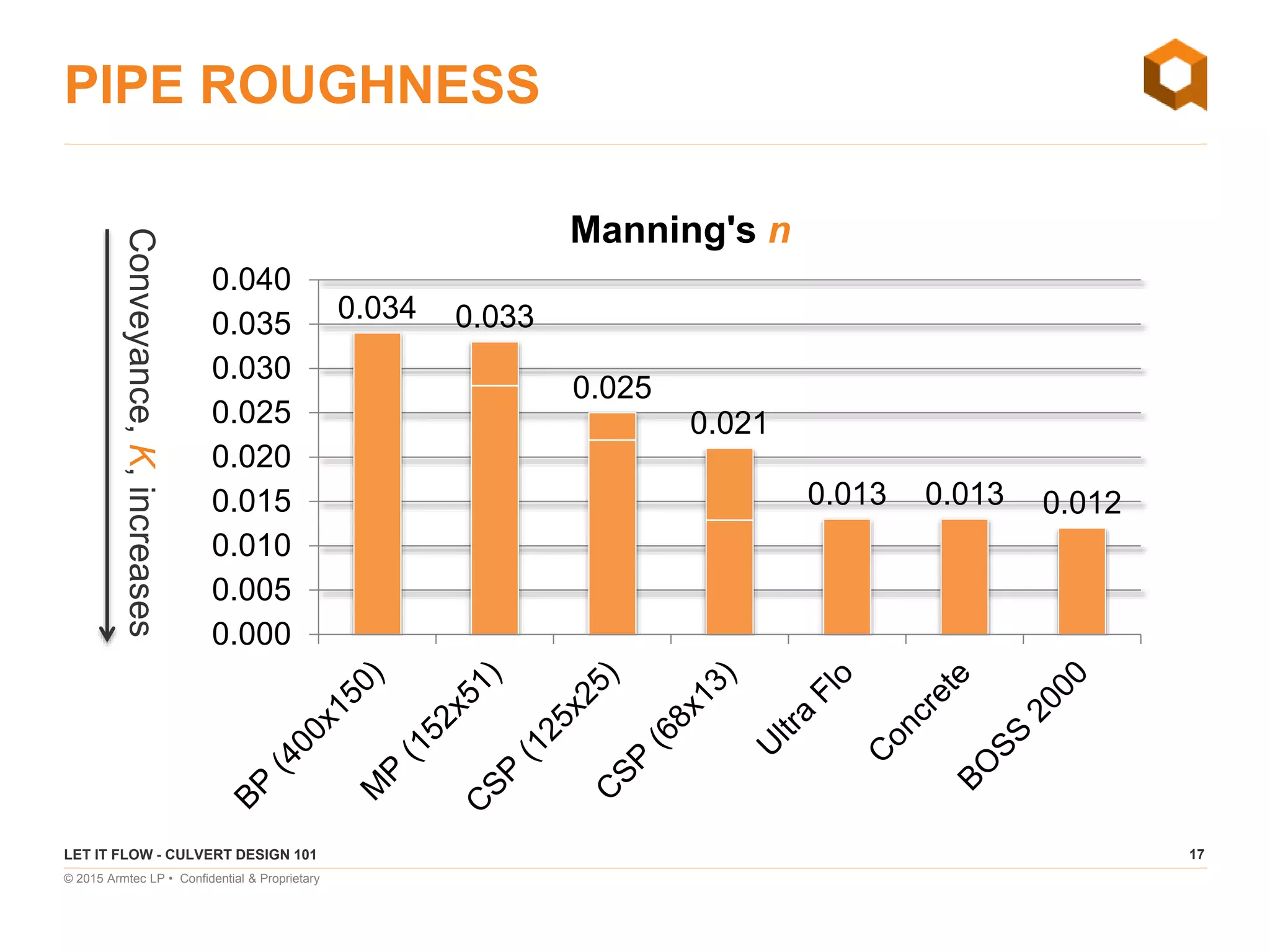

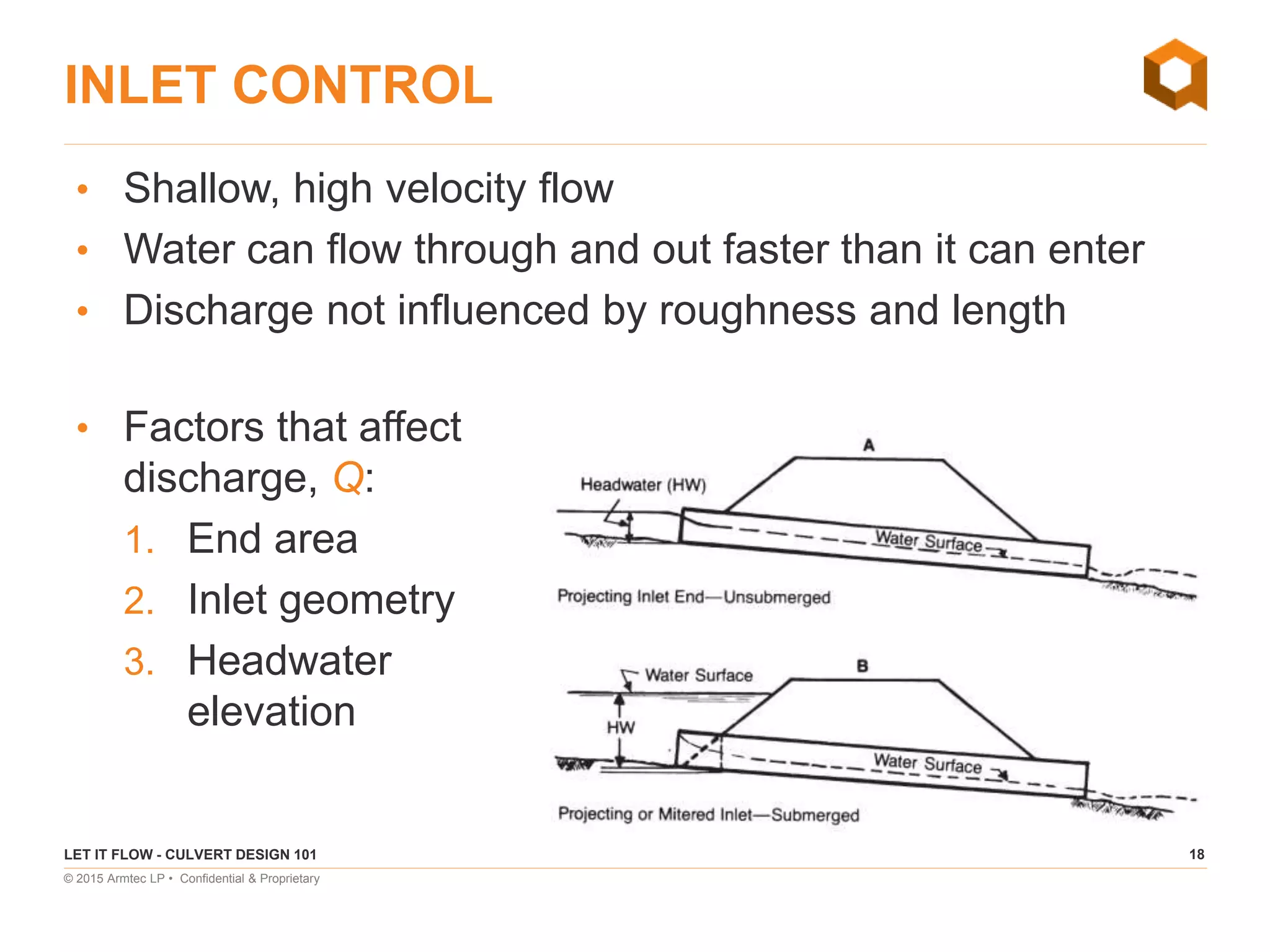

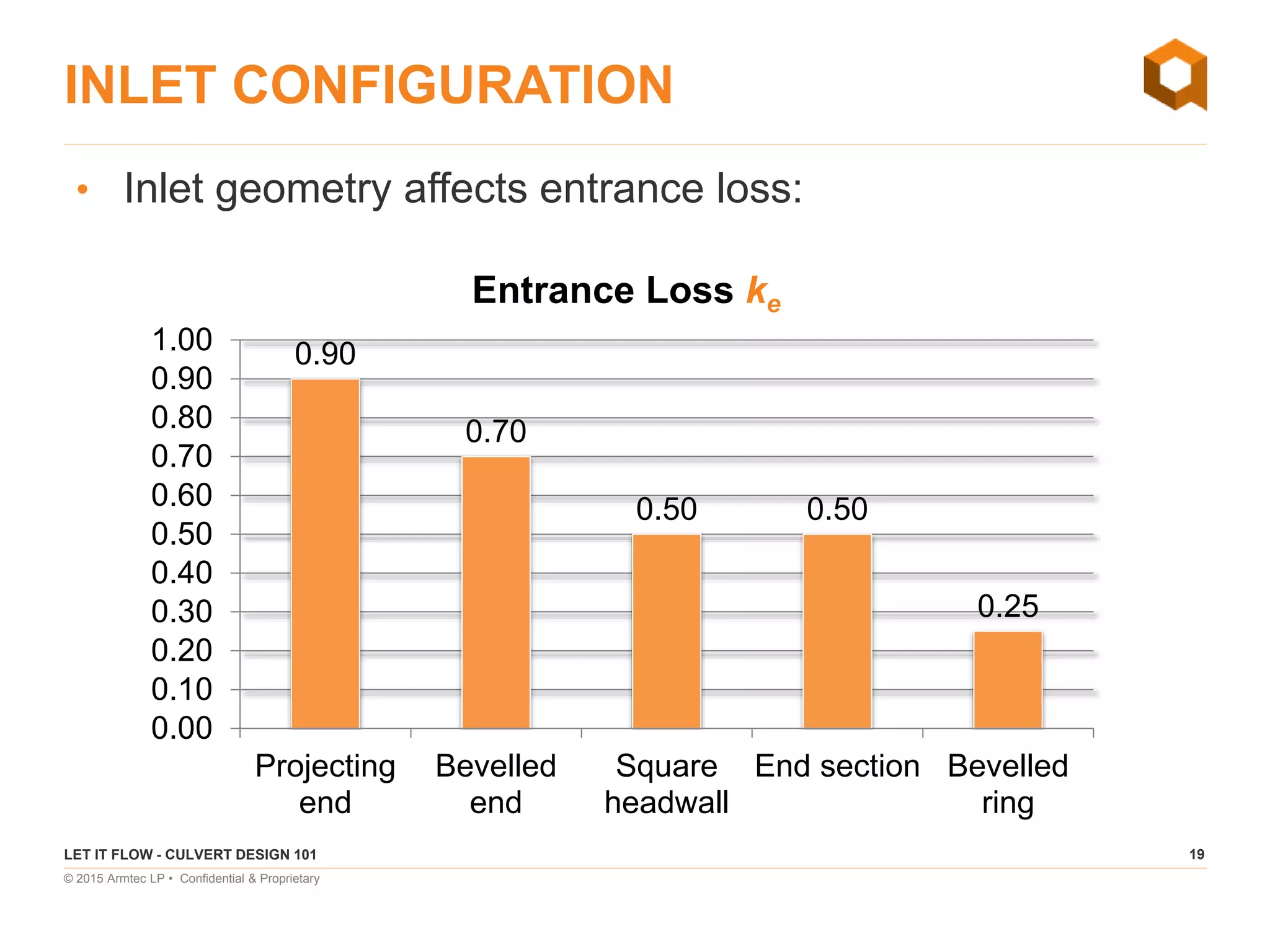

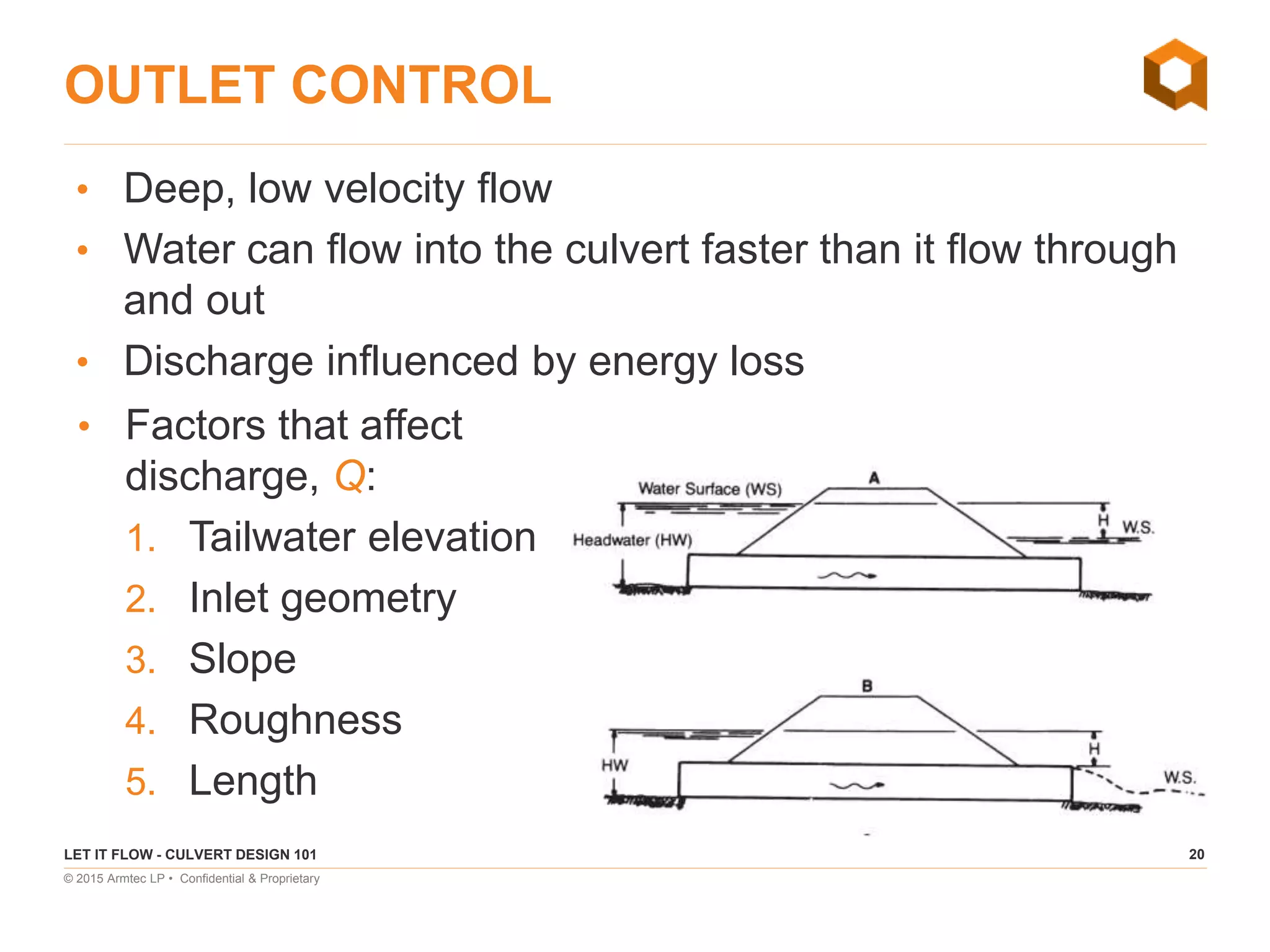

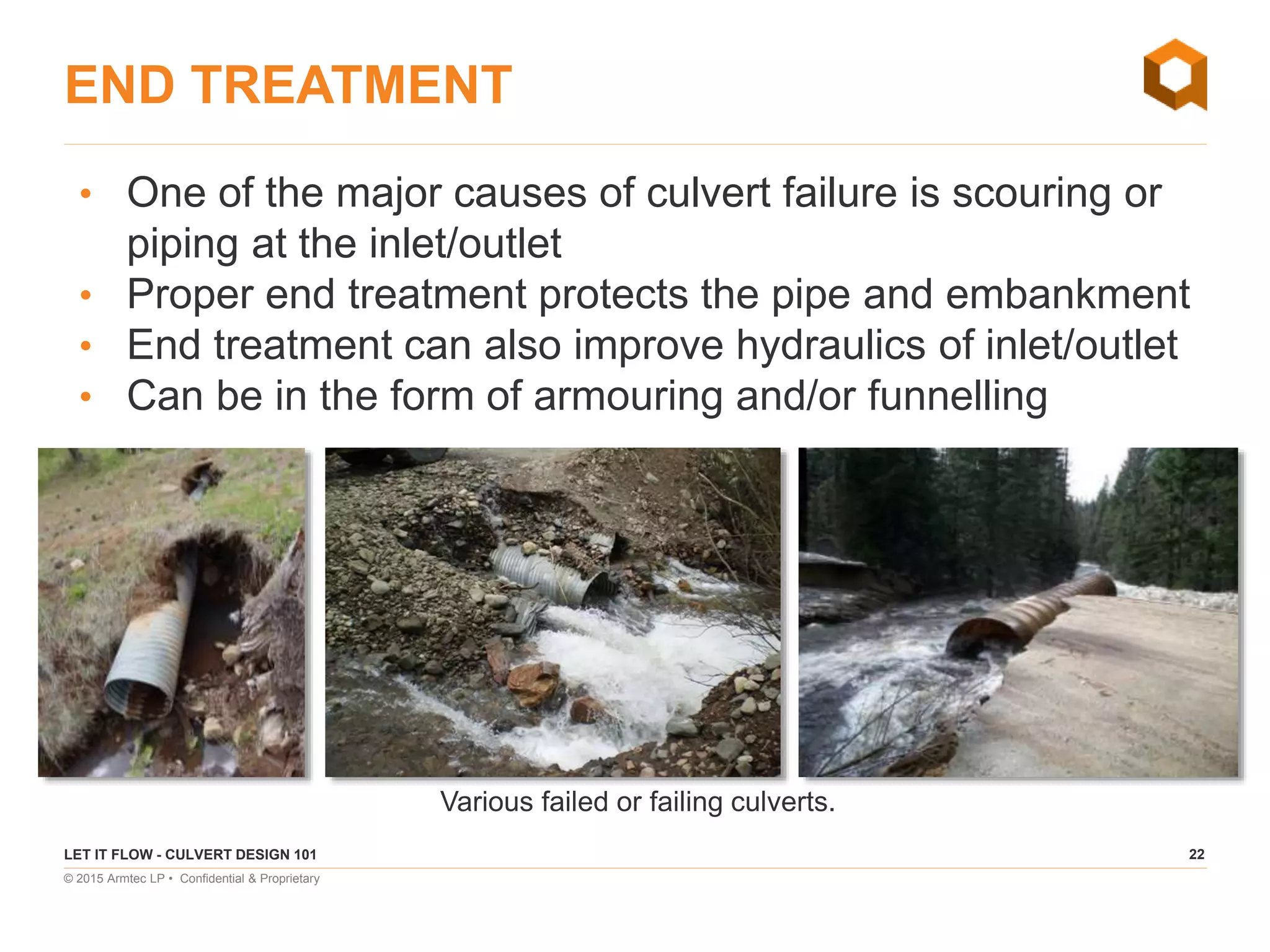

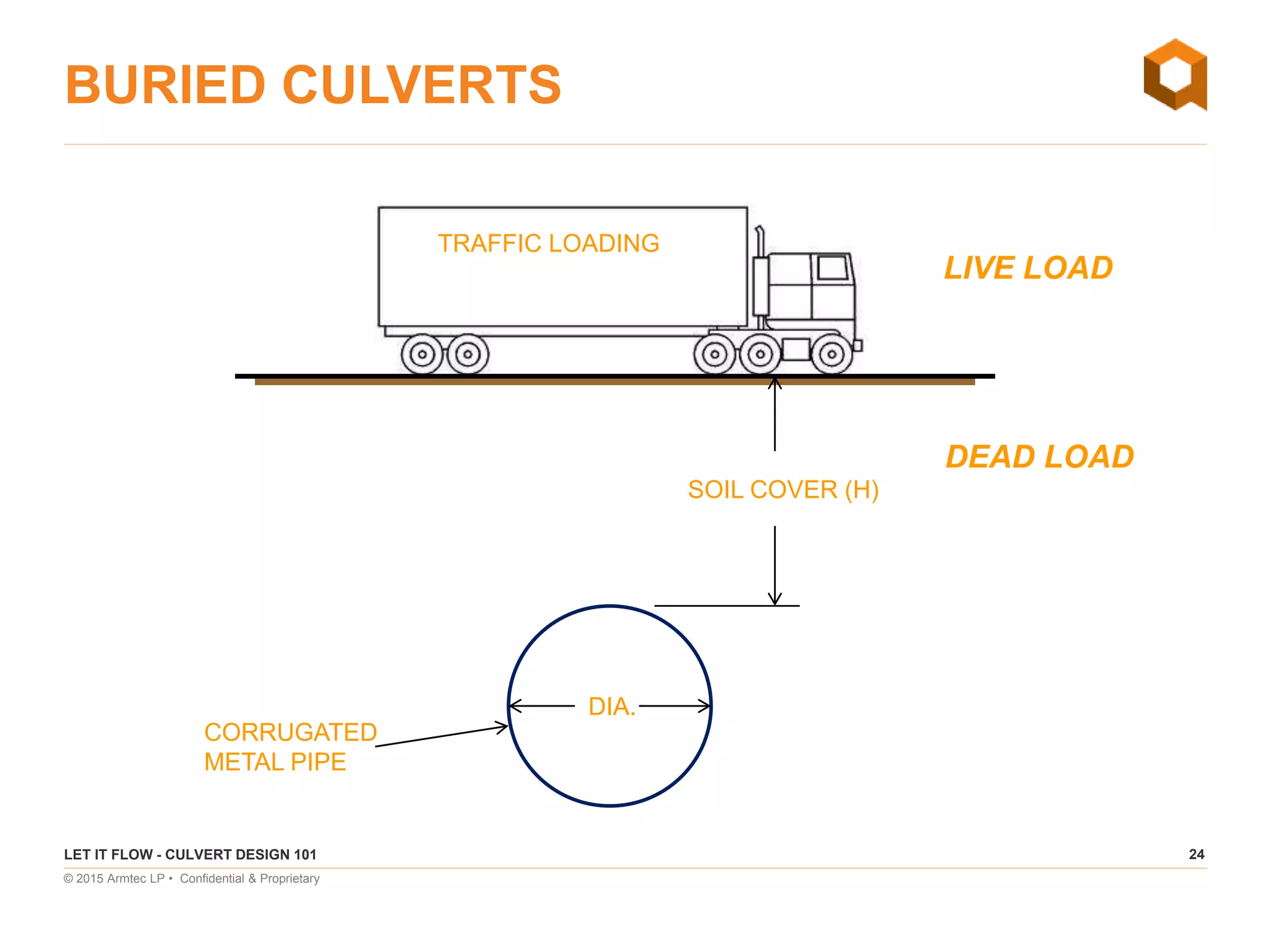

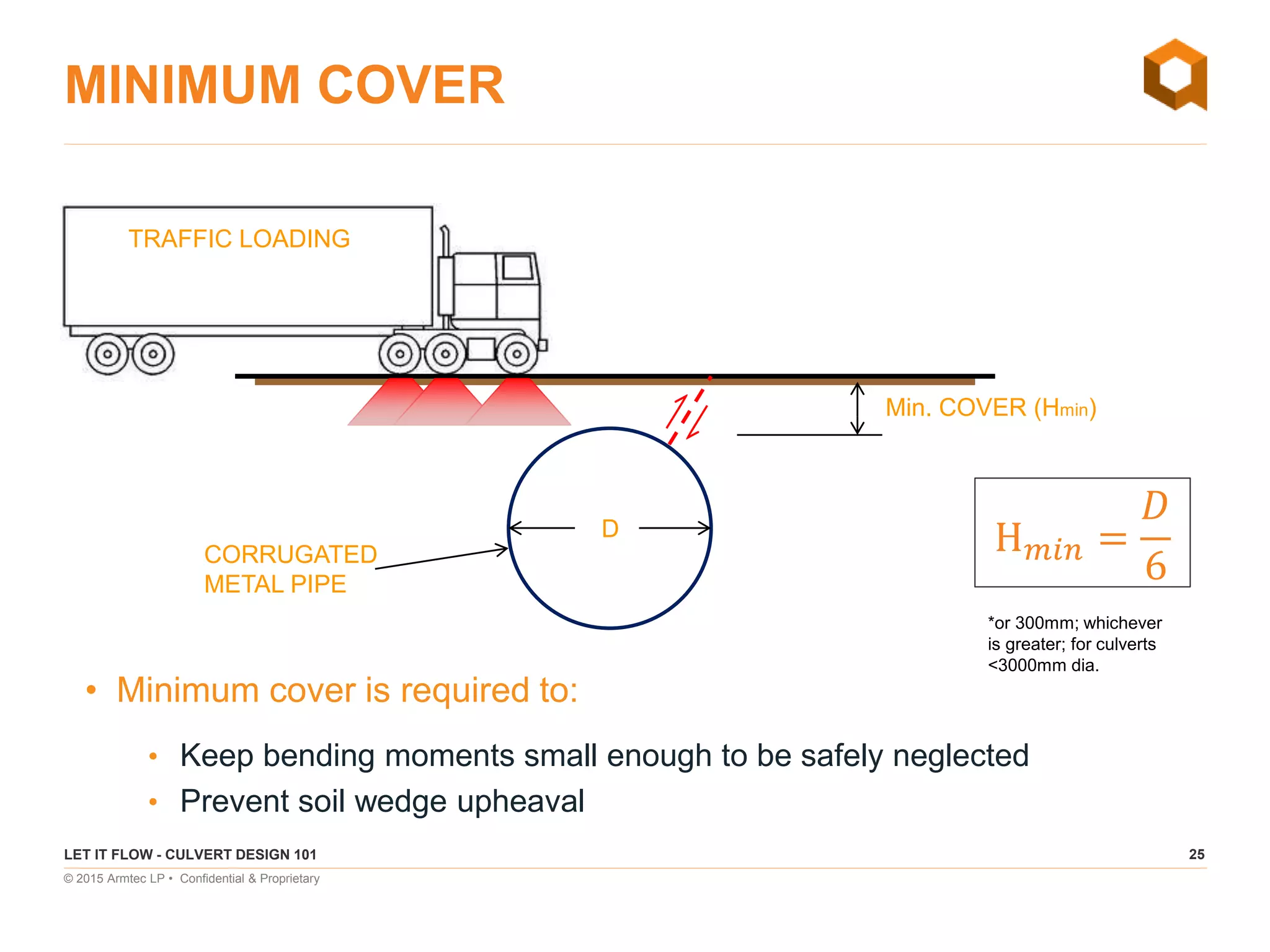

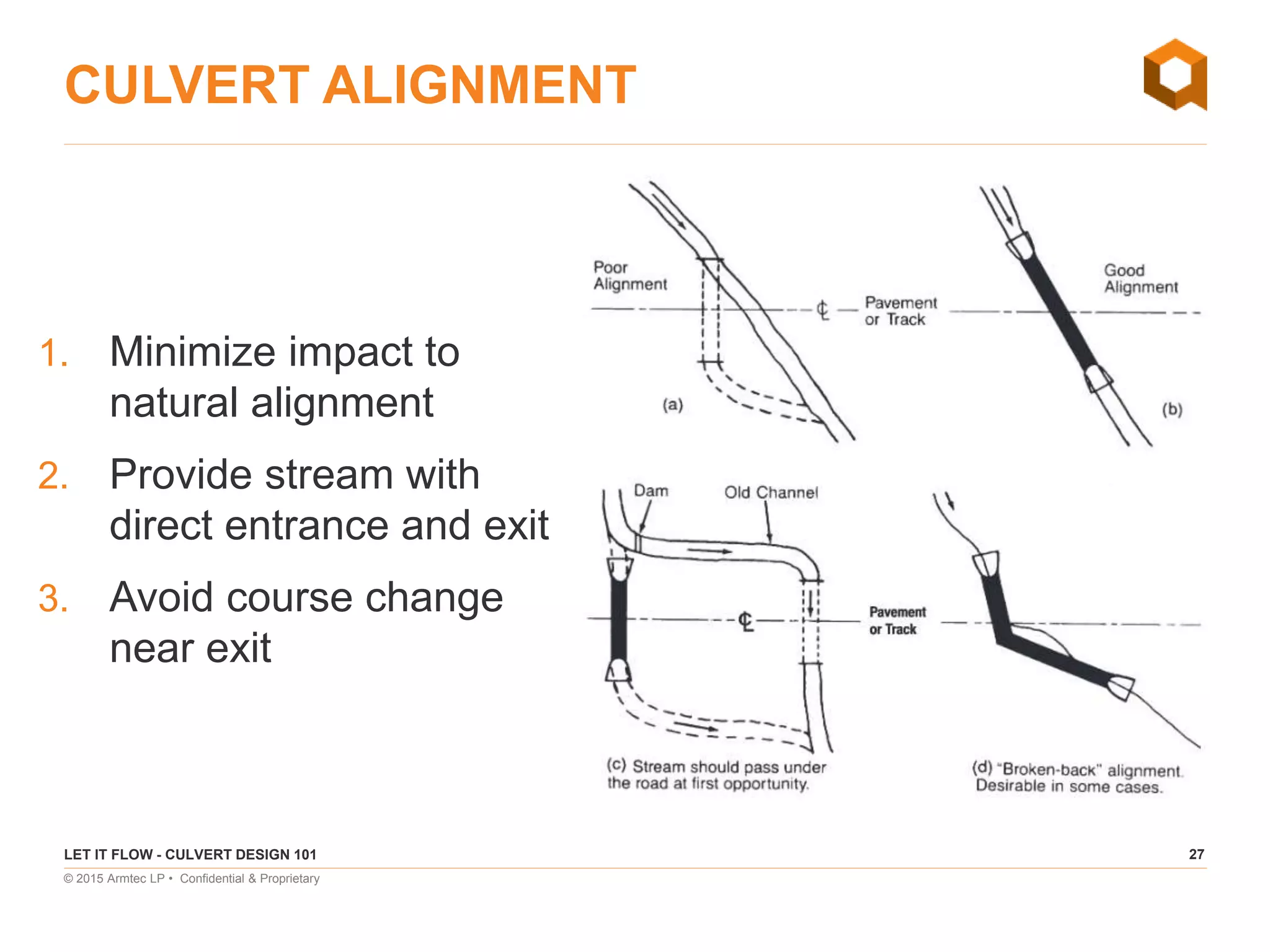

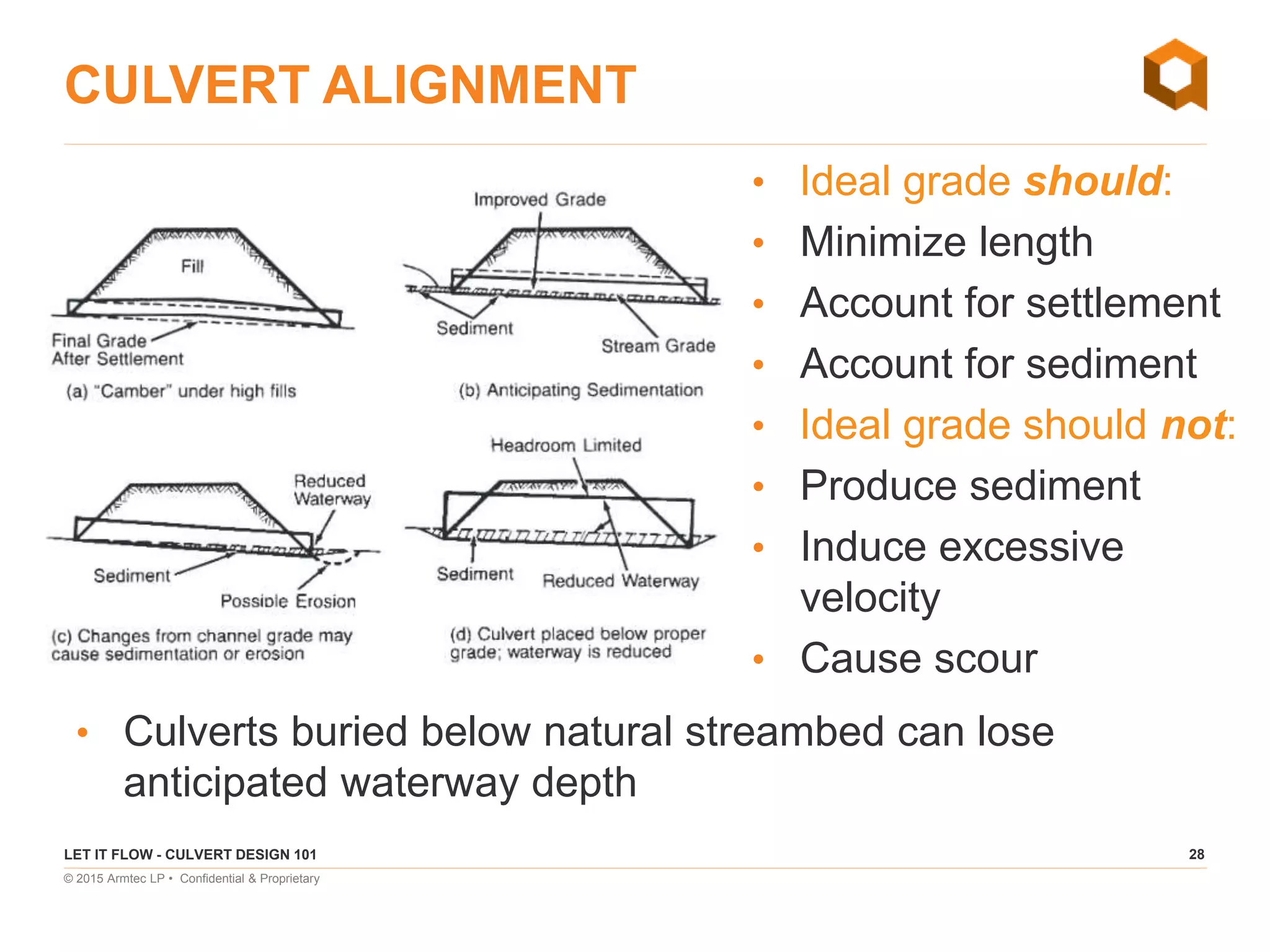

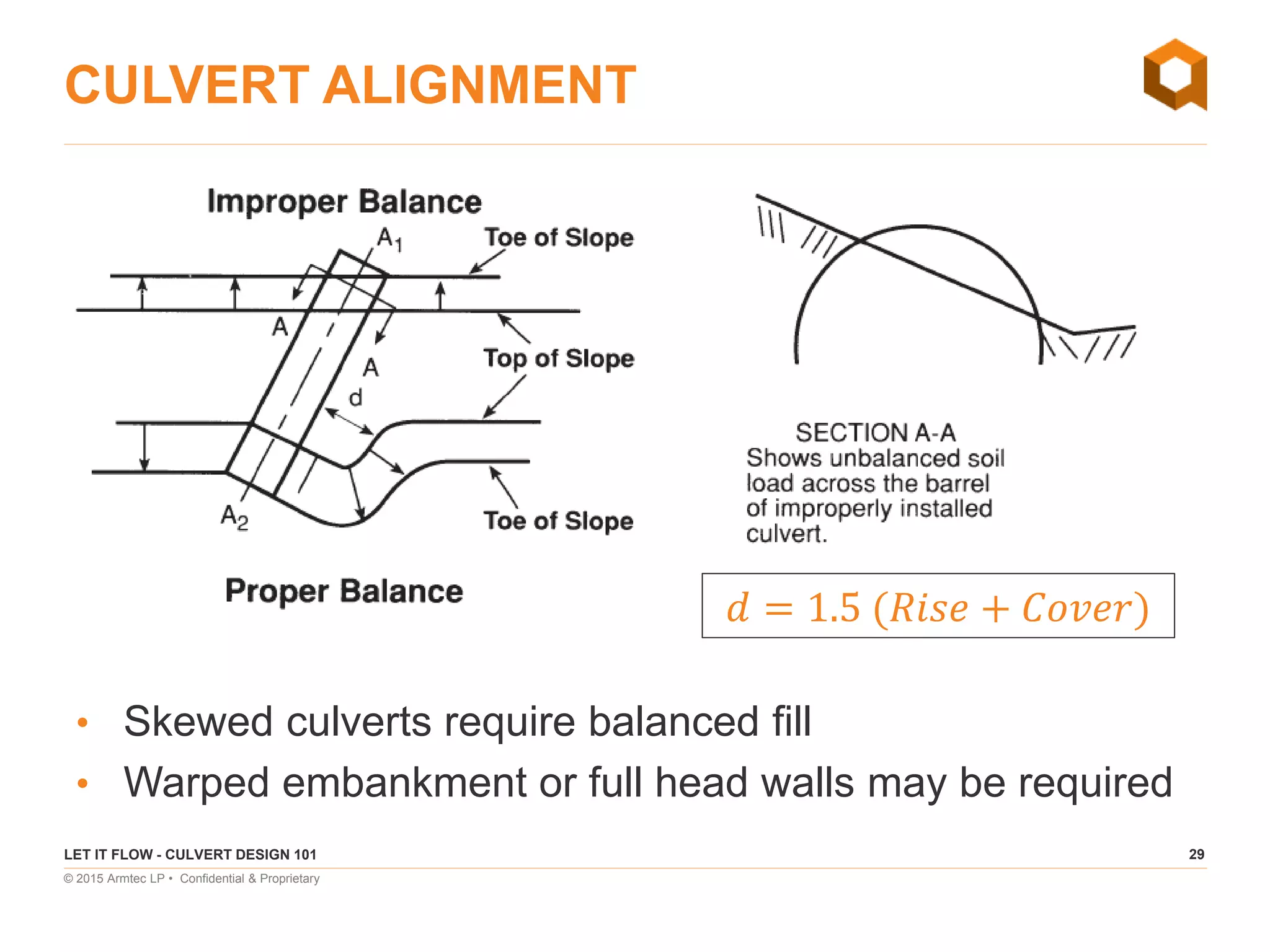

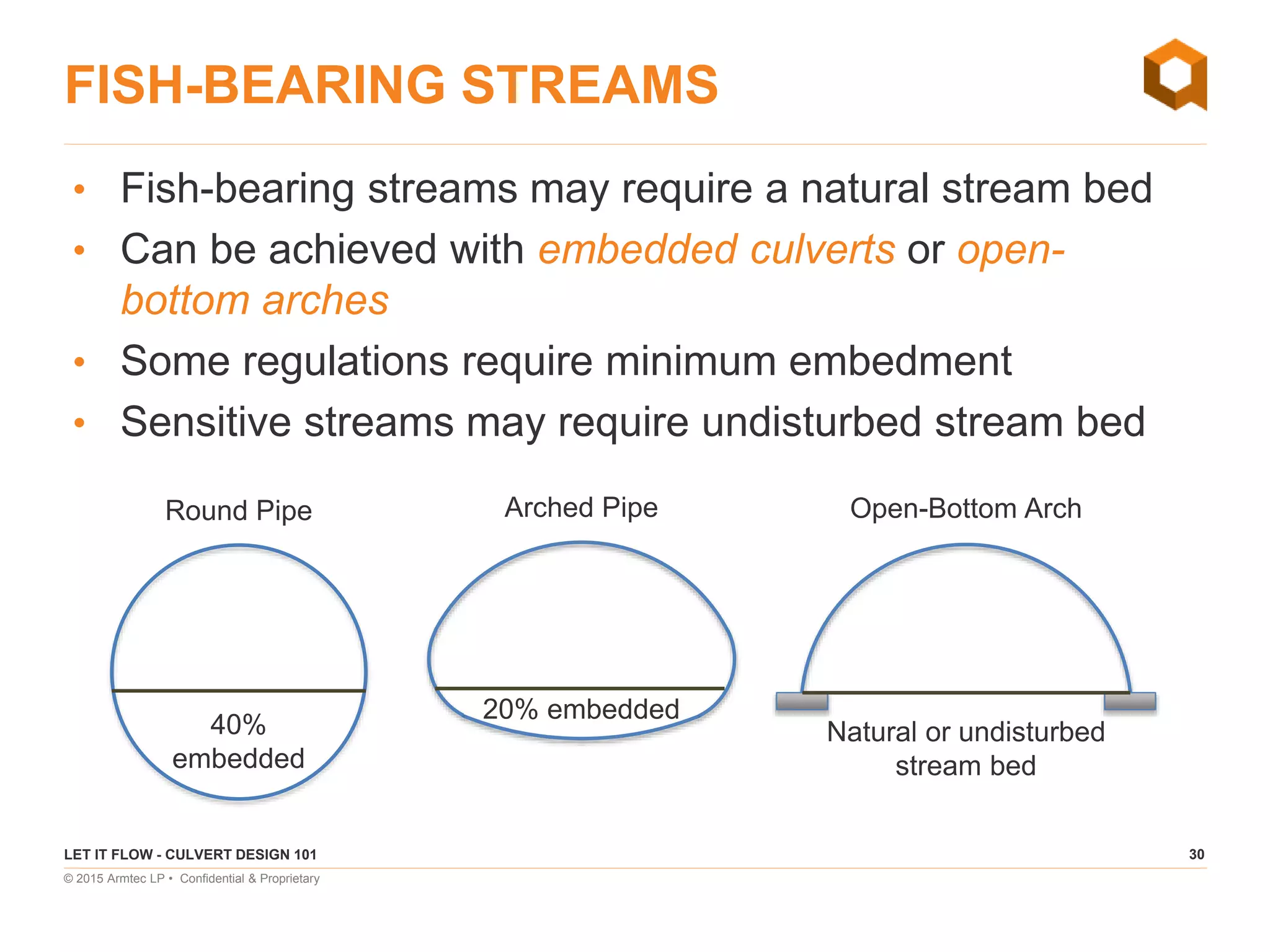

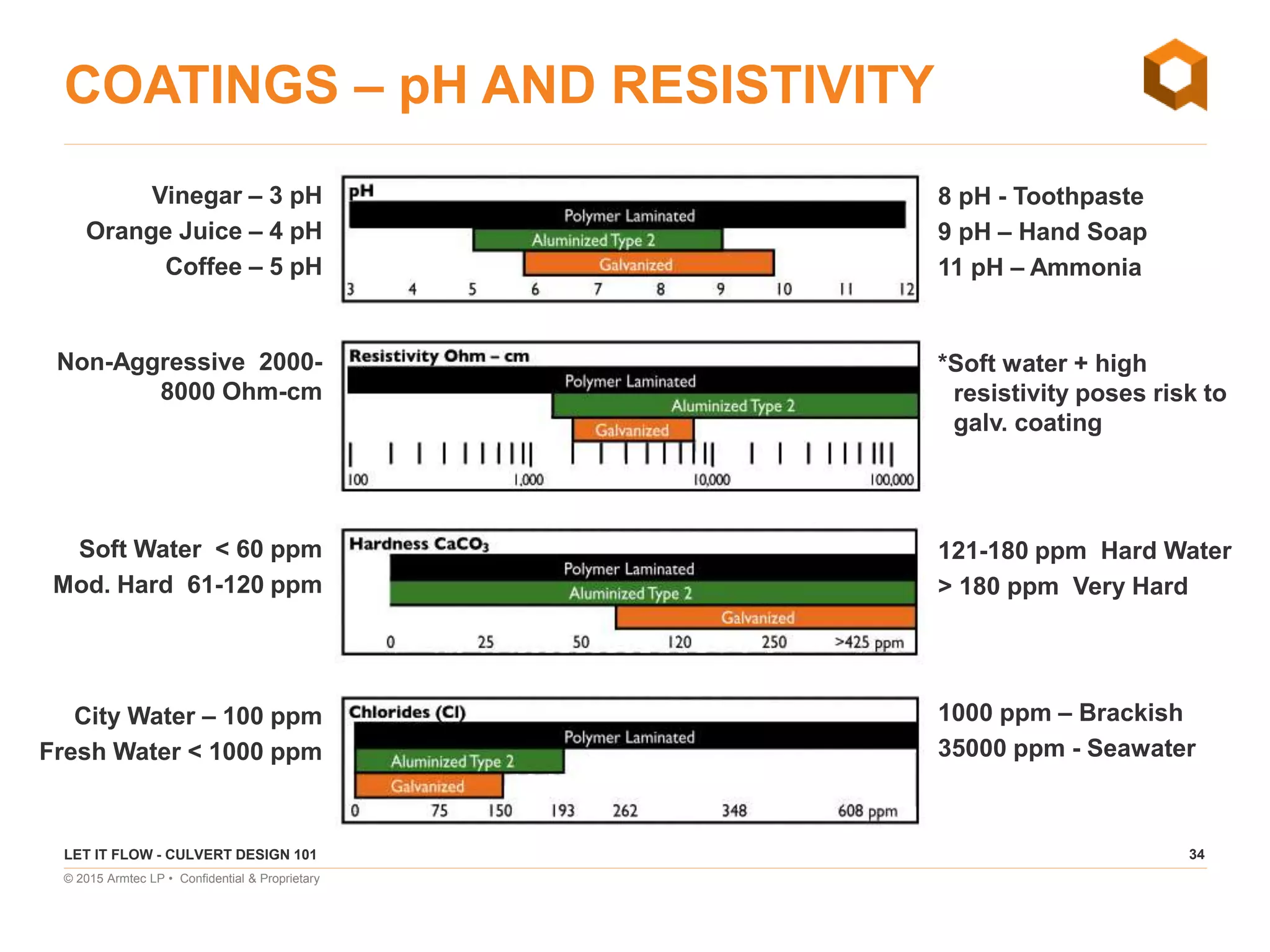

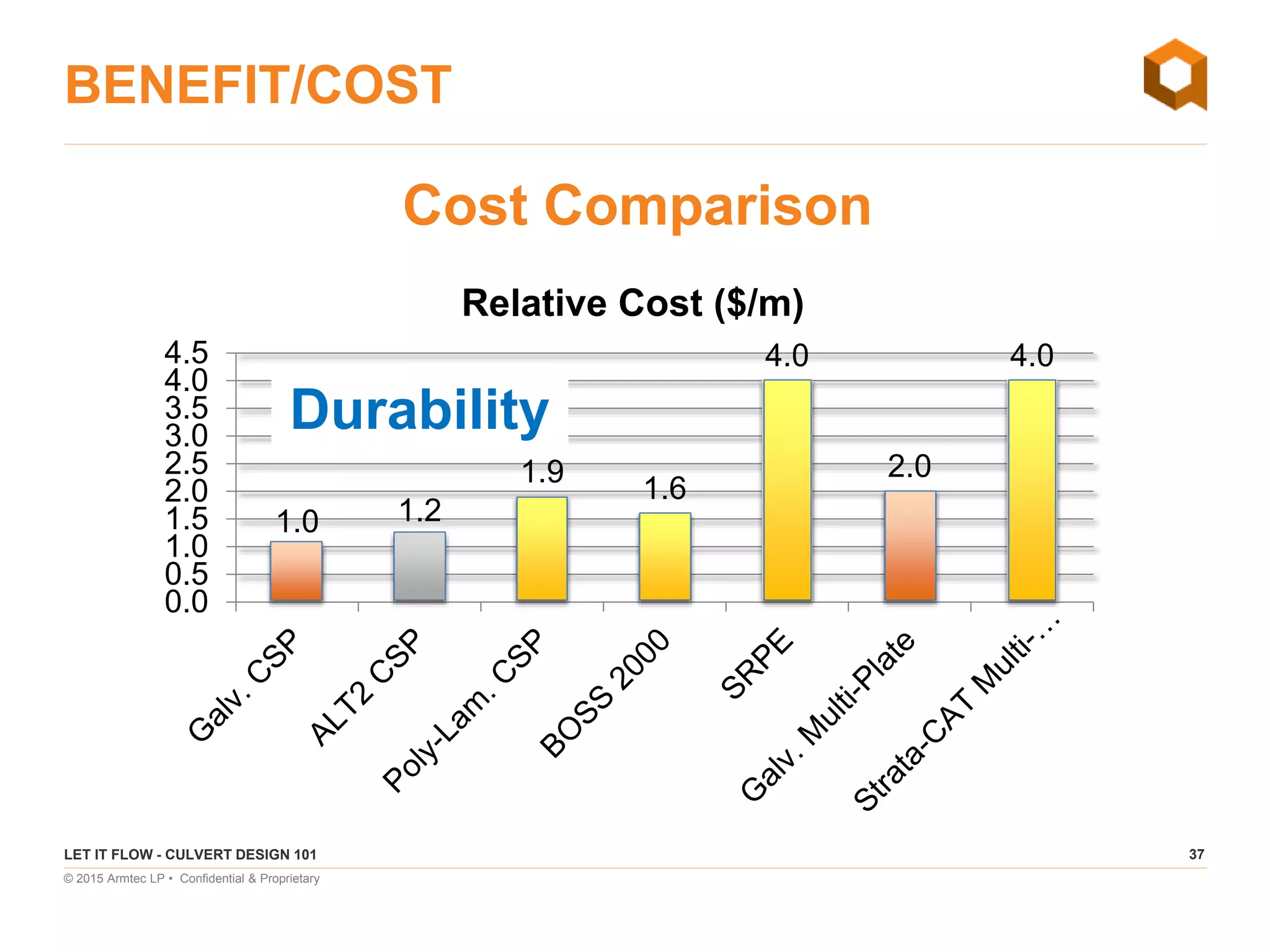

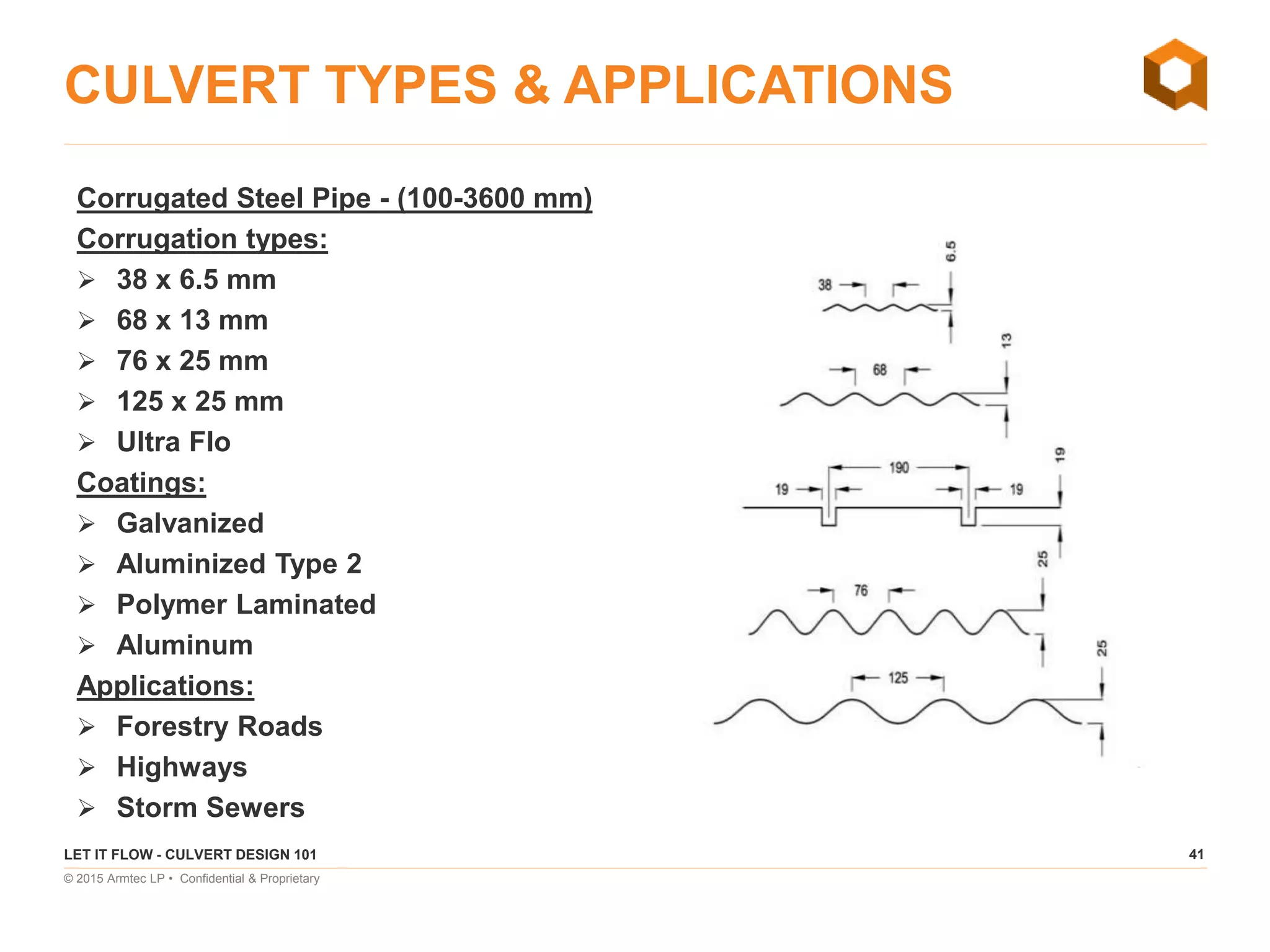

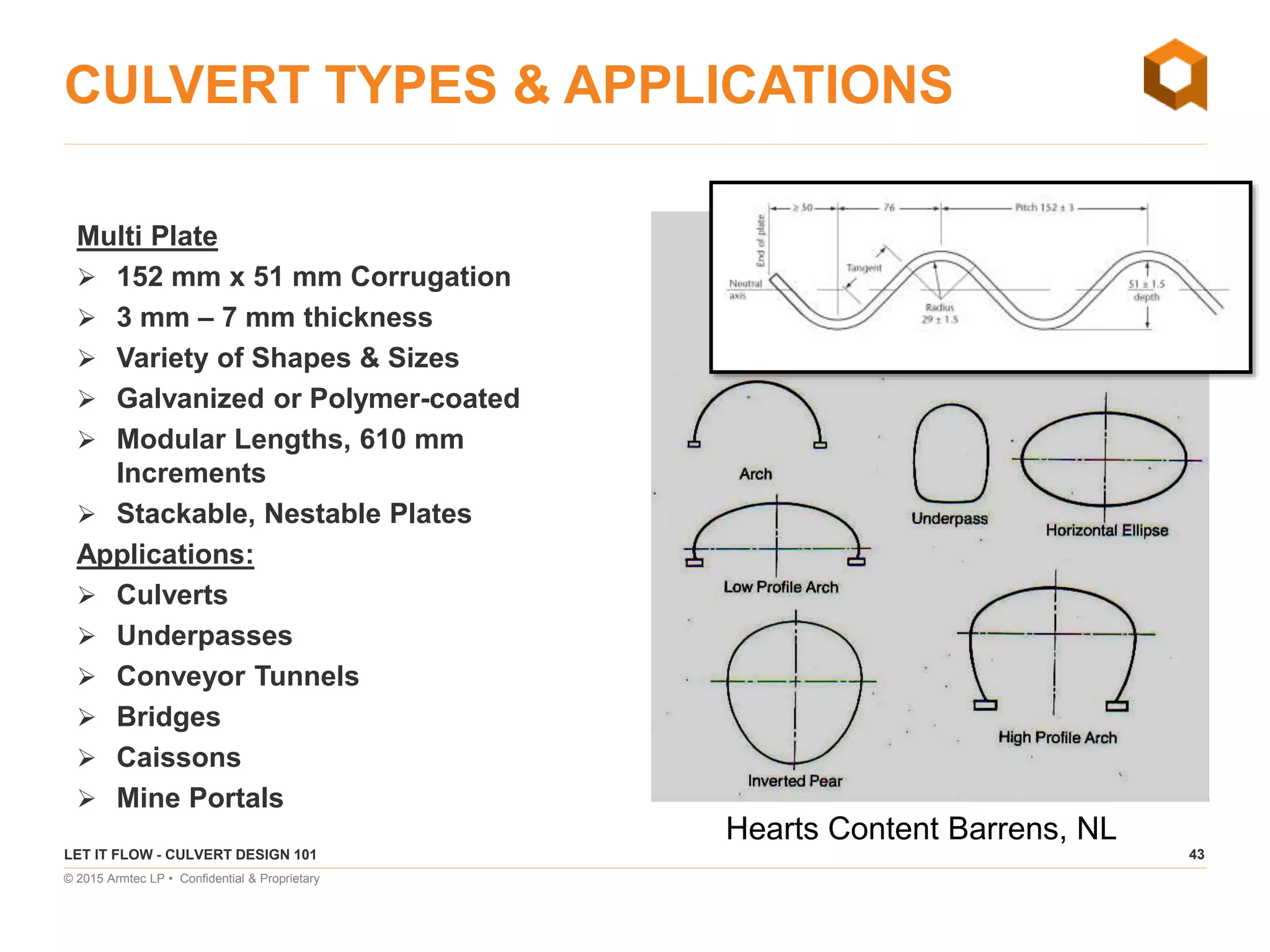

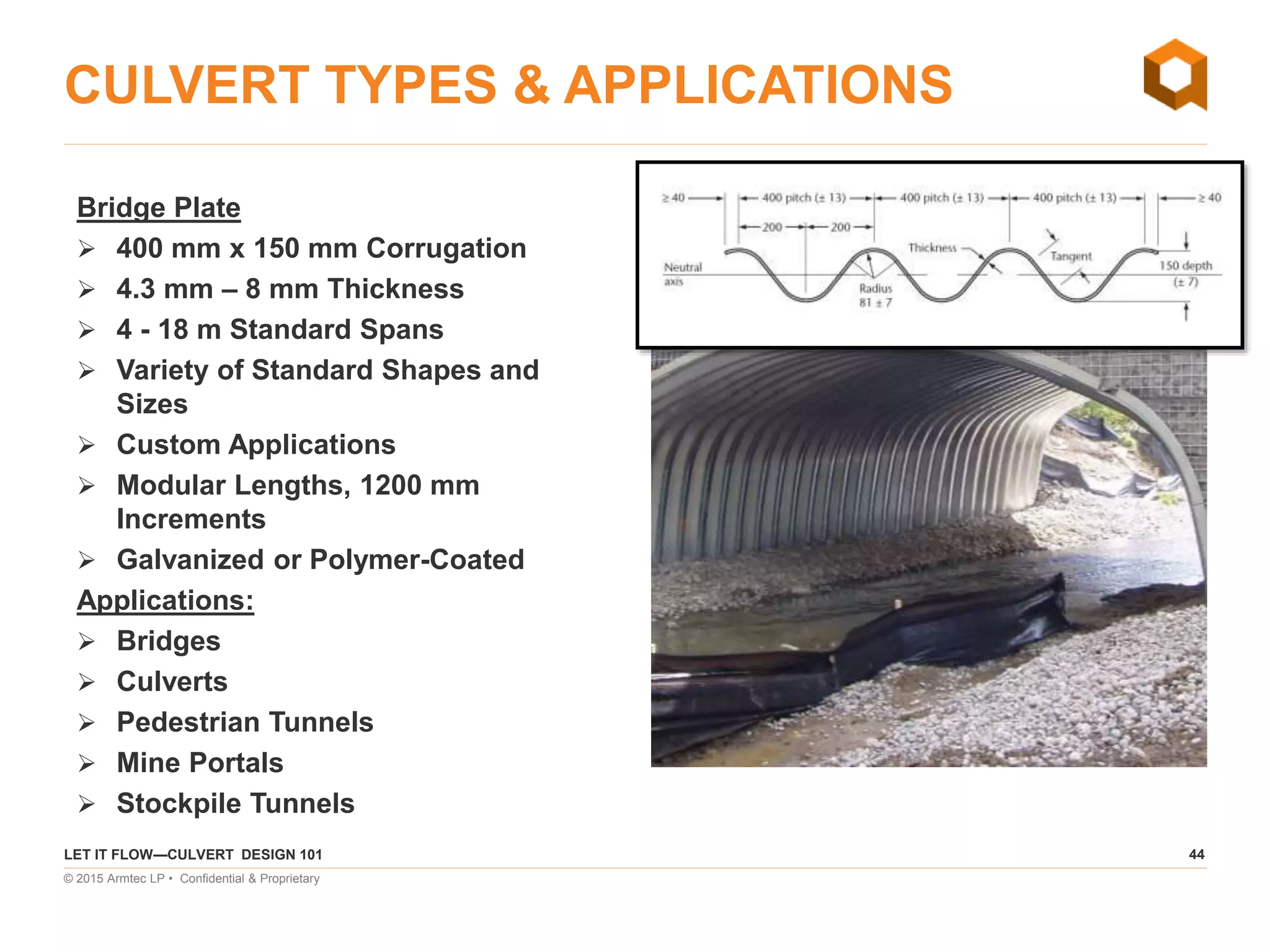

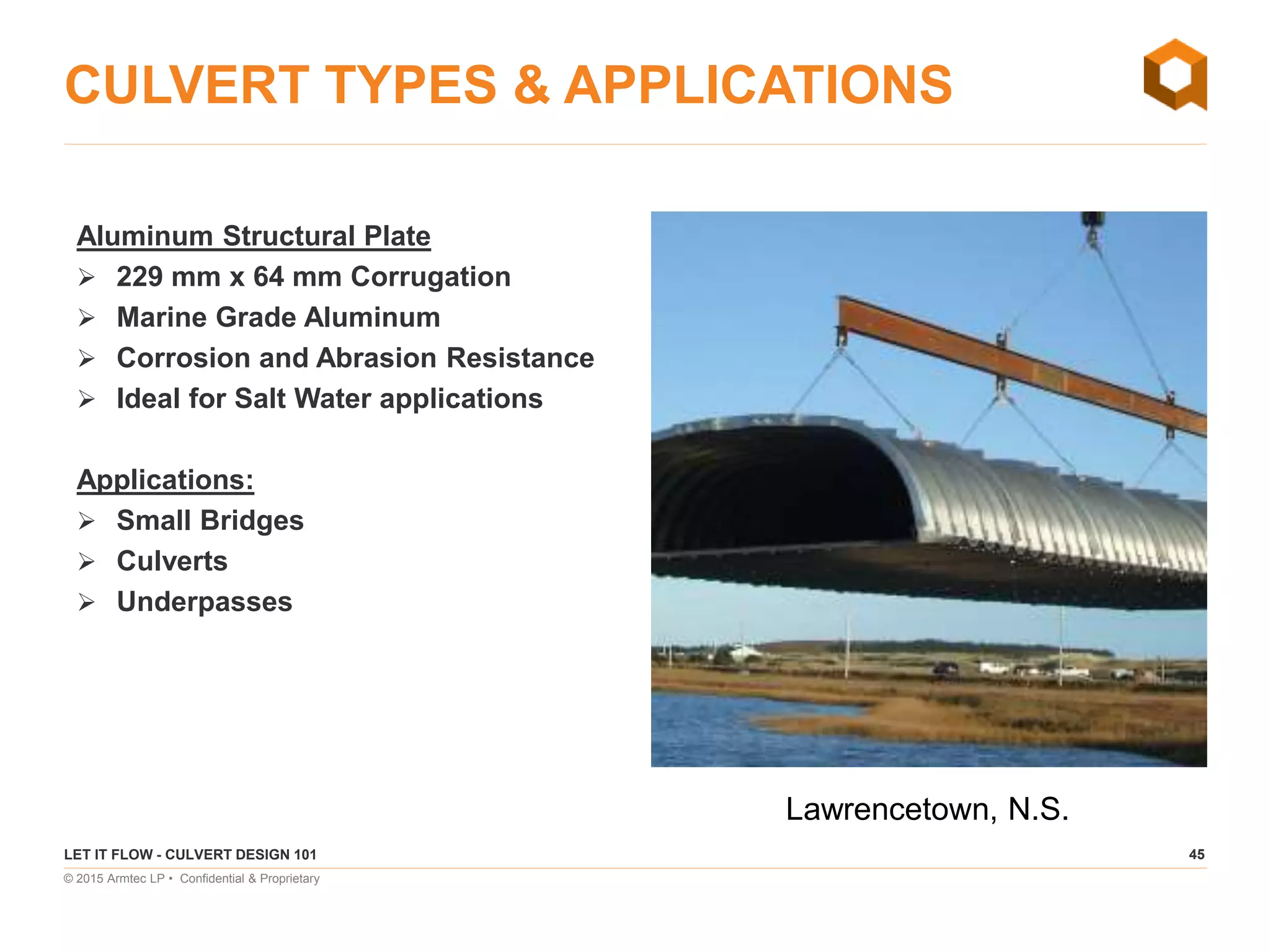

The document provides a technical overview of culvert design, covering essential aspects such as hydraulics, placement, durability, types, and applications. It discusses factors affecting flow rates, culvert capacity, and critical considerations for proper culvert installation to ensure longevity and efficiency. Additionally, it highlights various materials and coatings used in culvert construction to enhance durability against environmental conditions.