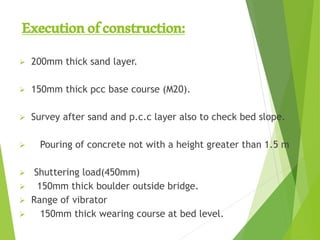

The document summarizes a student group's summer training project constructing a box culvert for the North Western Railway in Banswara, India. It describes the project details, components and materials of the box culvert, laboratory and field tests conducted, concrete mix design, construction layout, execution process, and structural analysis considering various loads. The students gained hands-on experience applying their classroom knowledge to the real-world construction of the box culvert.