The document is a chapter from the Department of Energy Fundamentals Handbook on Mechanical Science. It provides an overview of diesel engine fundamentals, including:

- A brief history of diesel engines and an introduction to their operating principles.

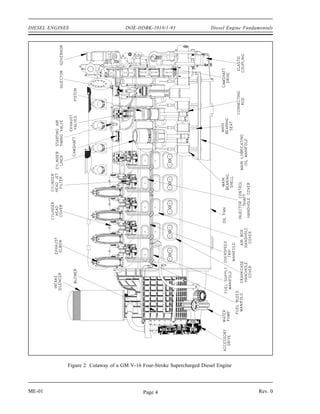

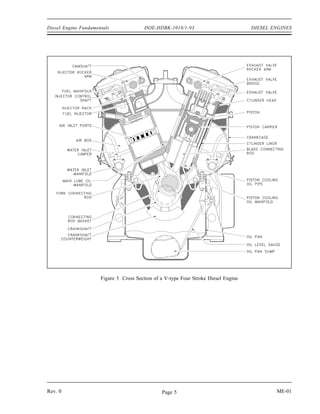

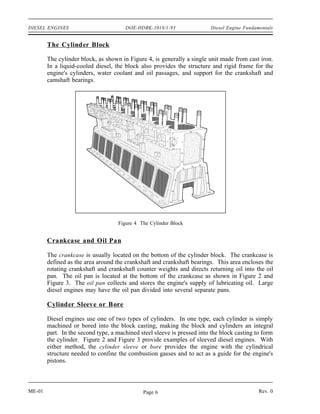

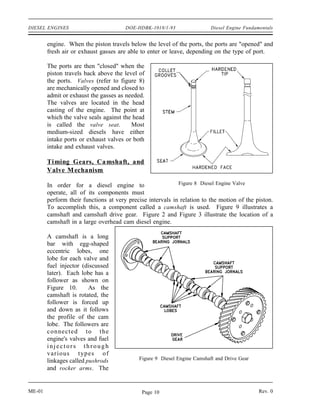

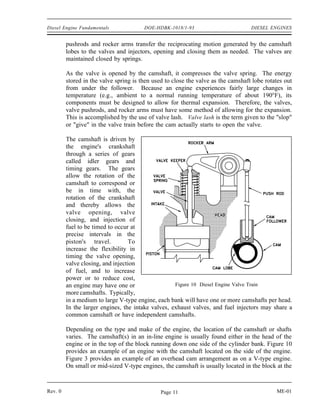

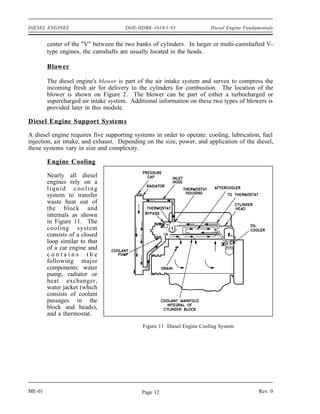

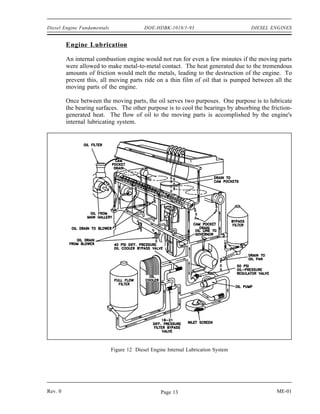

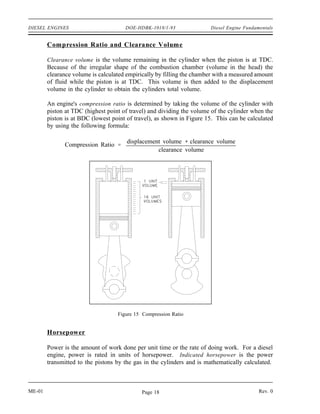

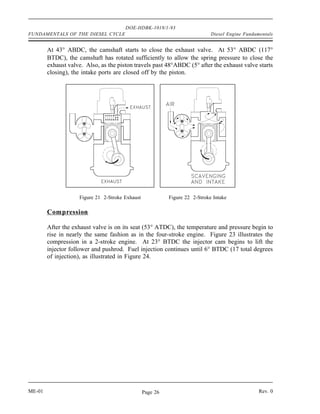

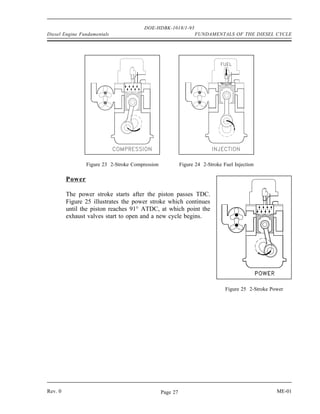

- Explanations of the basic components and cycles of 2-cycle and 4-cycle diesel engines.

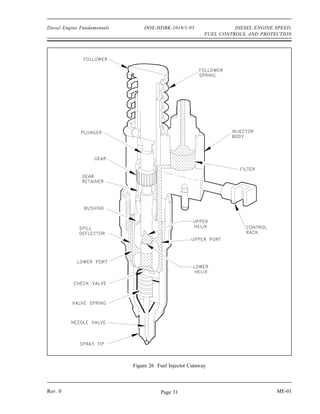

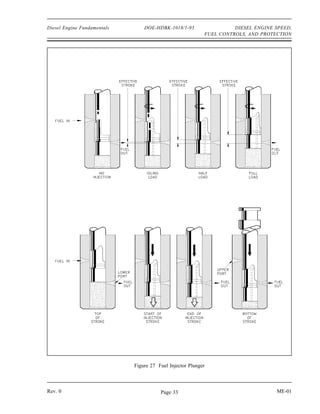

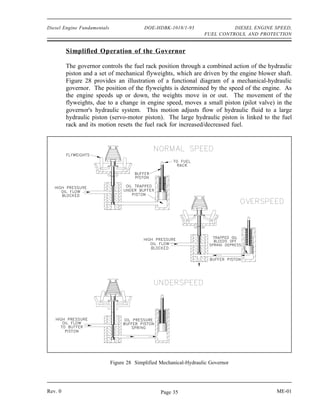

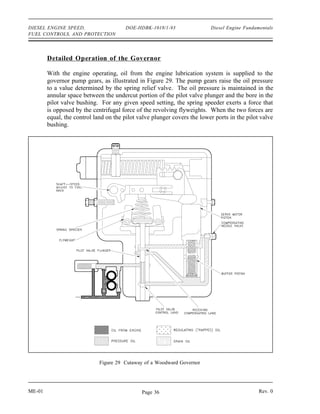

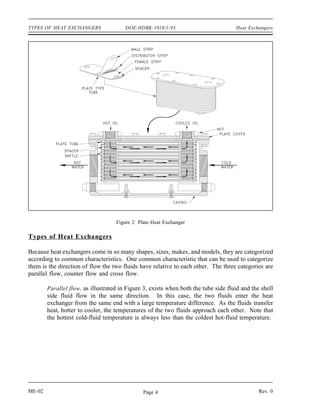

- Descriptions of engine governors, fuel injectors, and protective features commonly used in diesel engines.

The chapter aims to give readers a foundational understanding of diesel engine operation to facilitate the safe and reliable operation of mechanical systems in DOE nuclear facilities.