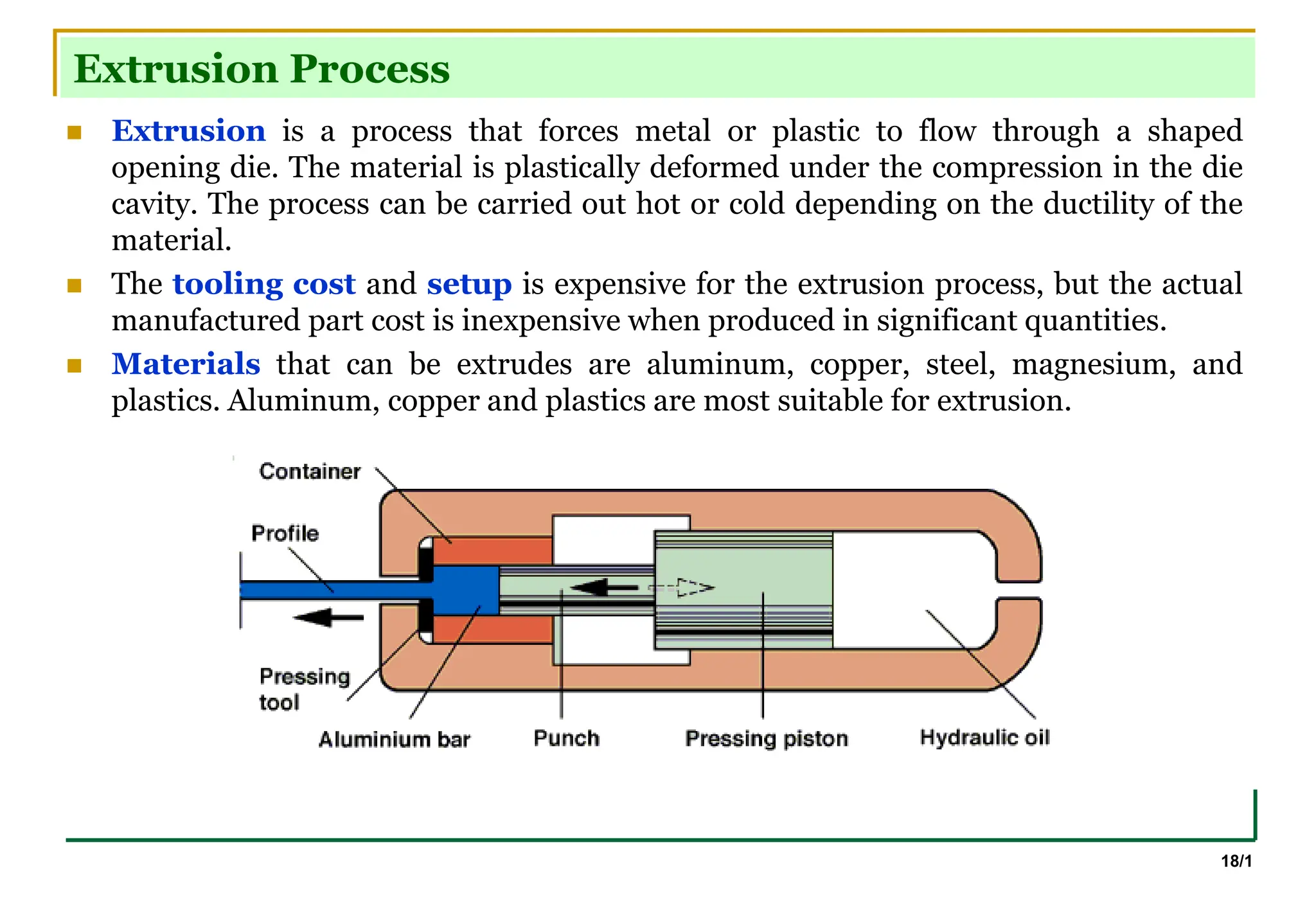

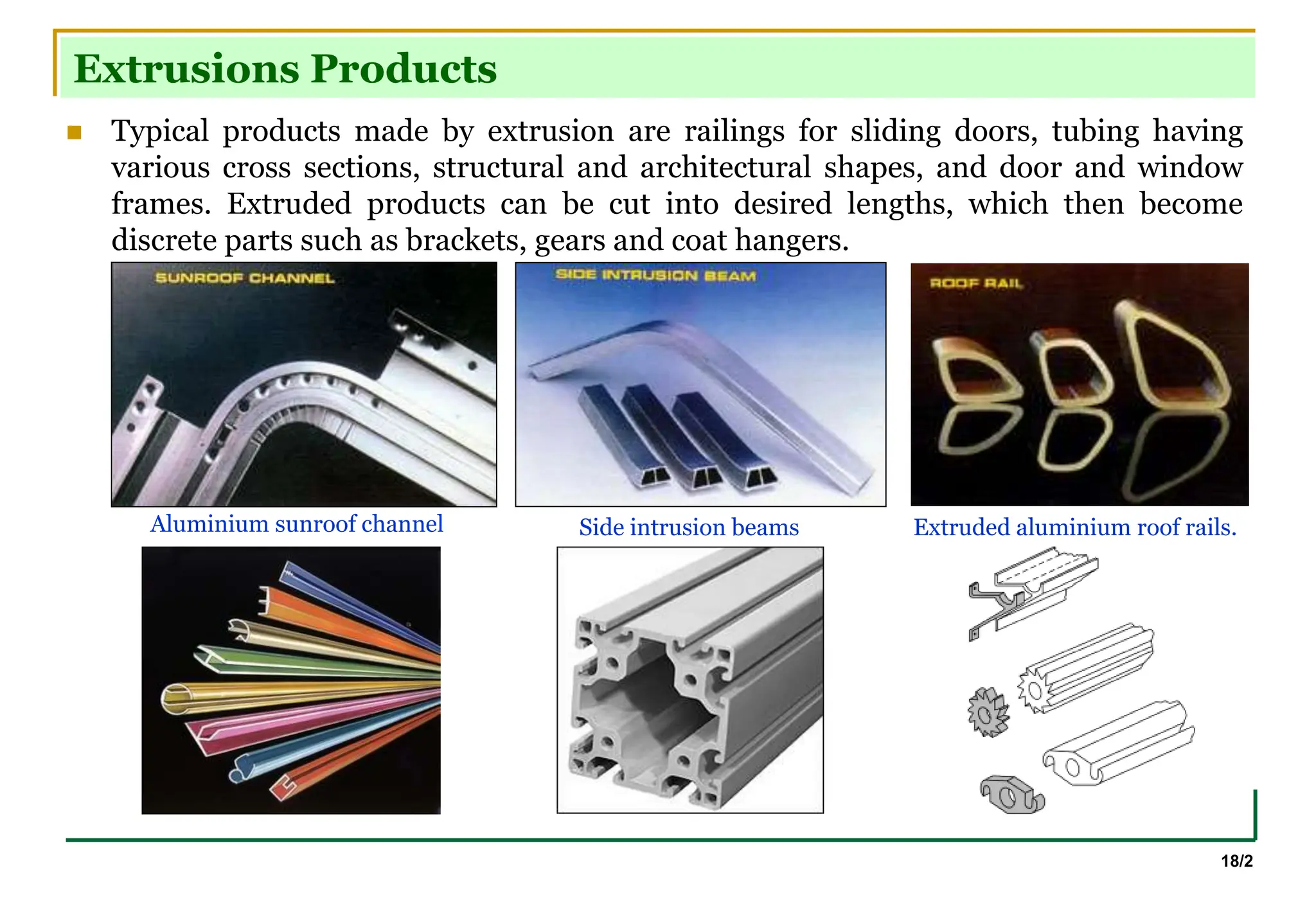

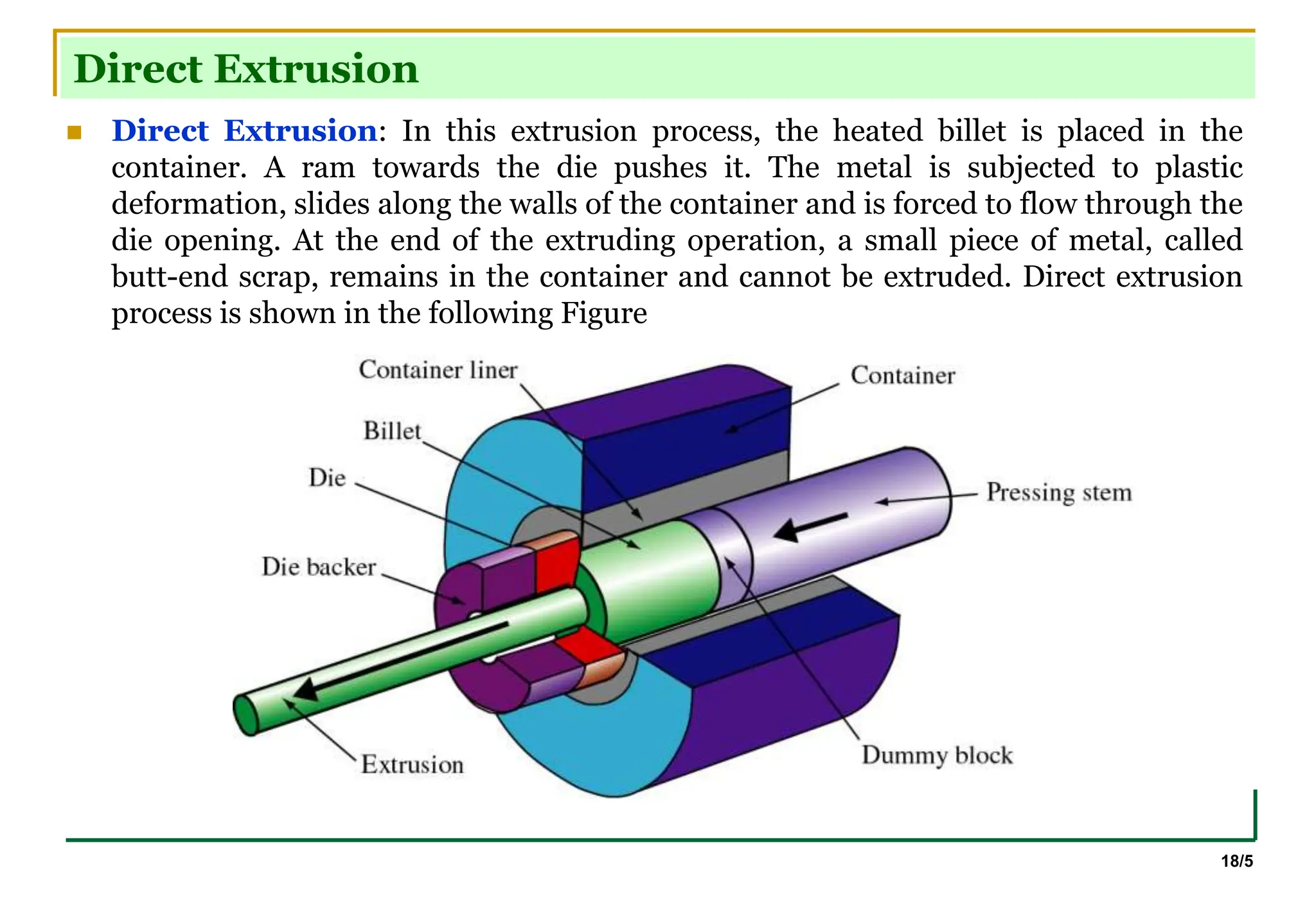

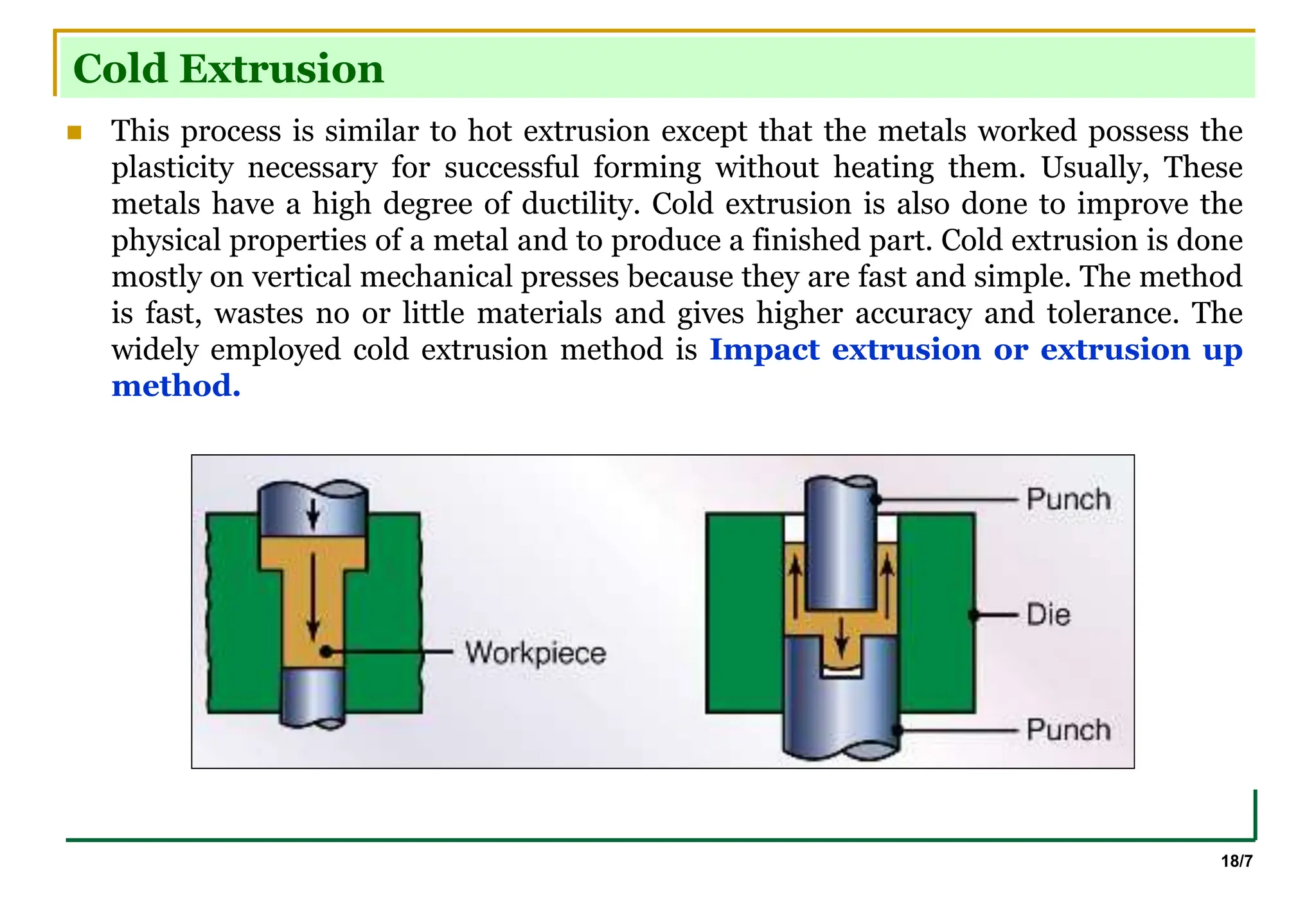

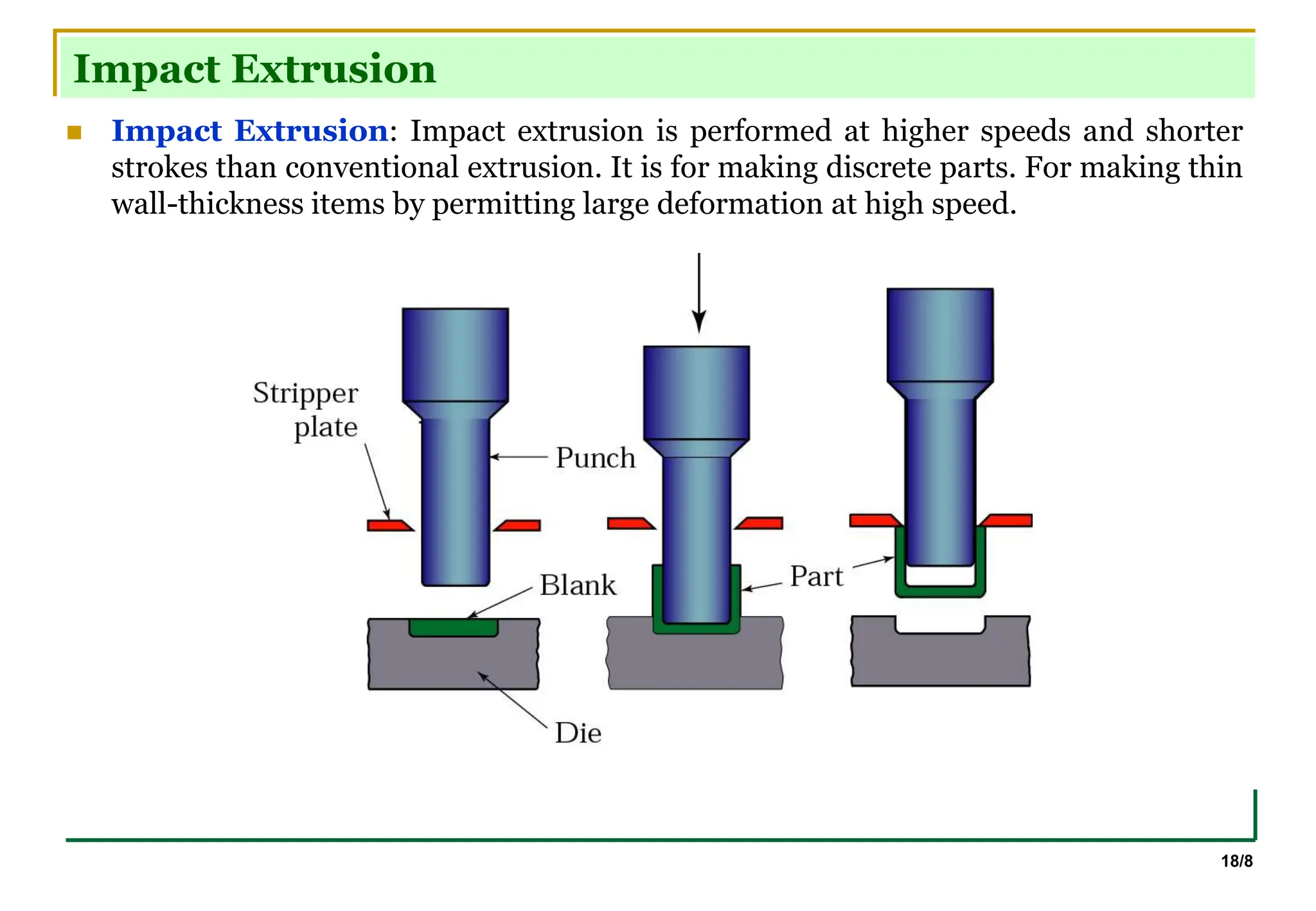

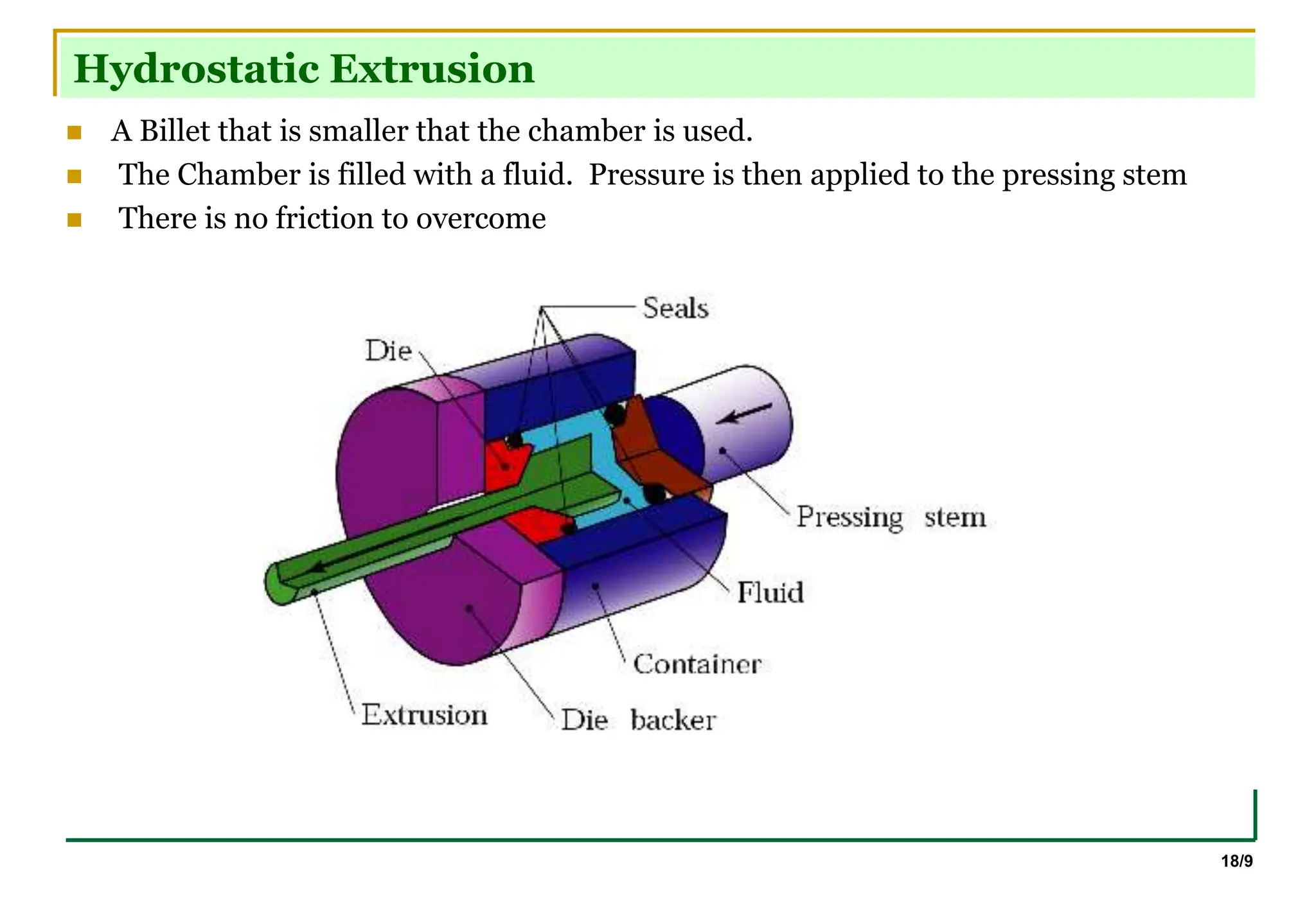

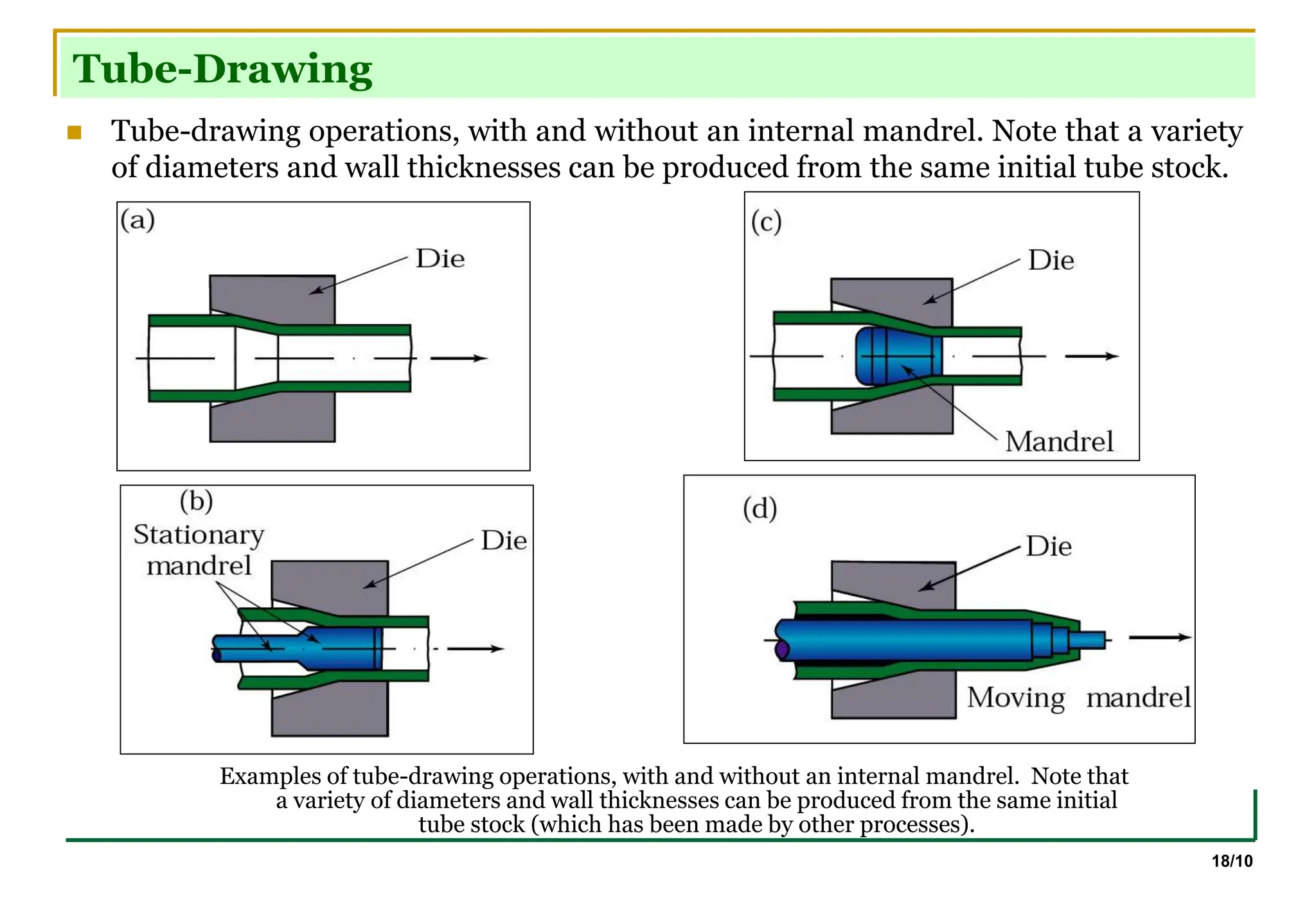

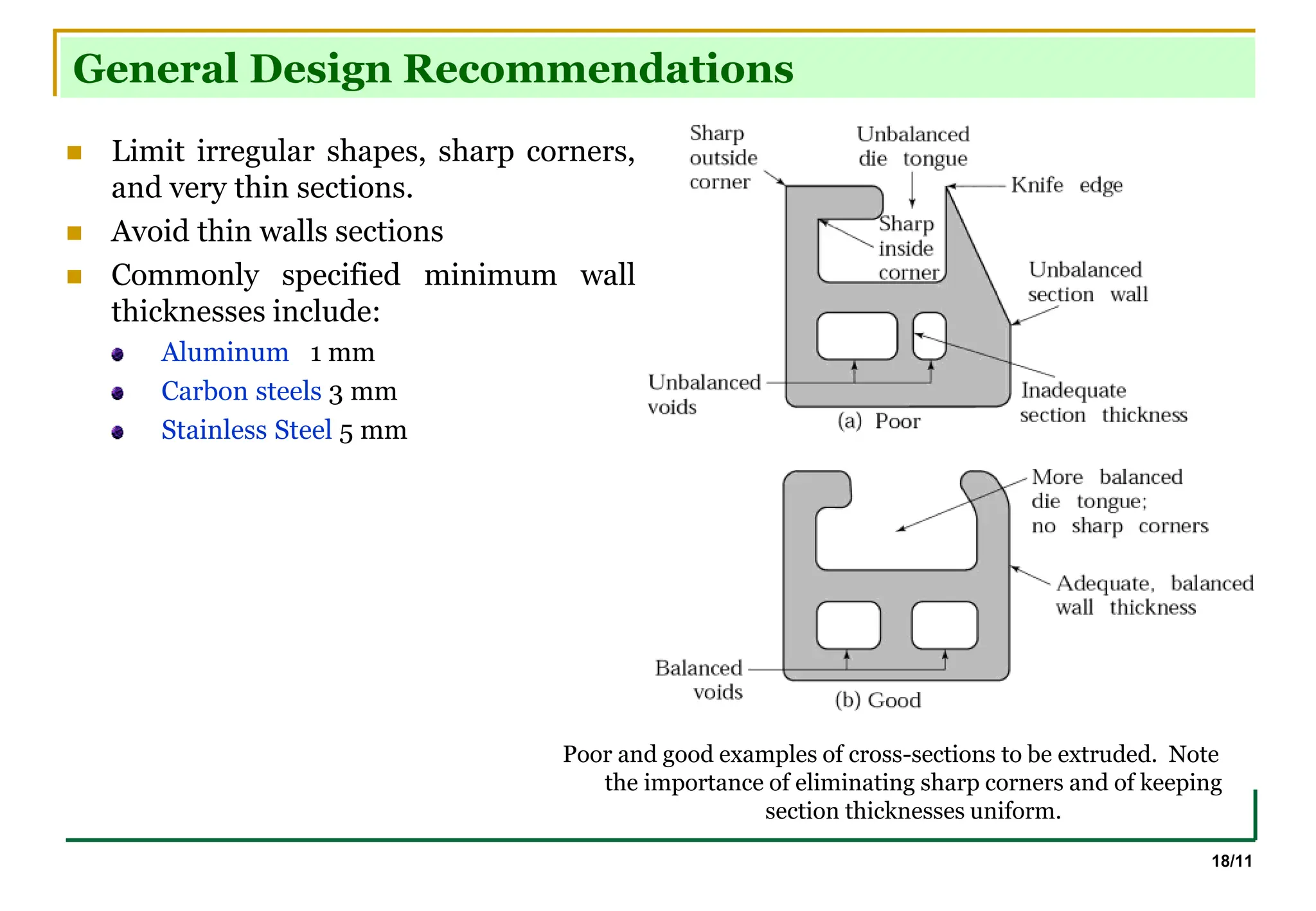

Extrusion is a process that forces metal or plastic through a shaped die opening, plastically deforming the material. It can be done hot or cold depending on the material's ductility. Common extruded products include tubing, structural shapes, and frames. The process involves pushing or pulling the material through the die, either directly or indirectly. It allows for a wide range of cross-sectional shapes and high dimensional accuracy compared to other processes like rolling. However, extrusion also has higher costs and waste than some other manufacturing methods.