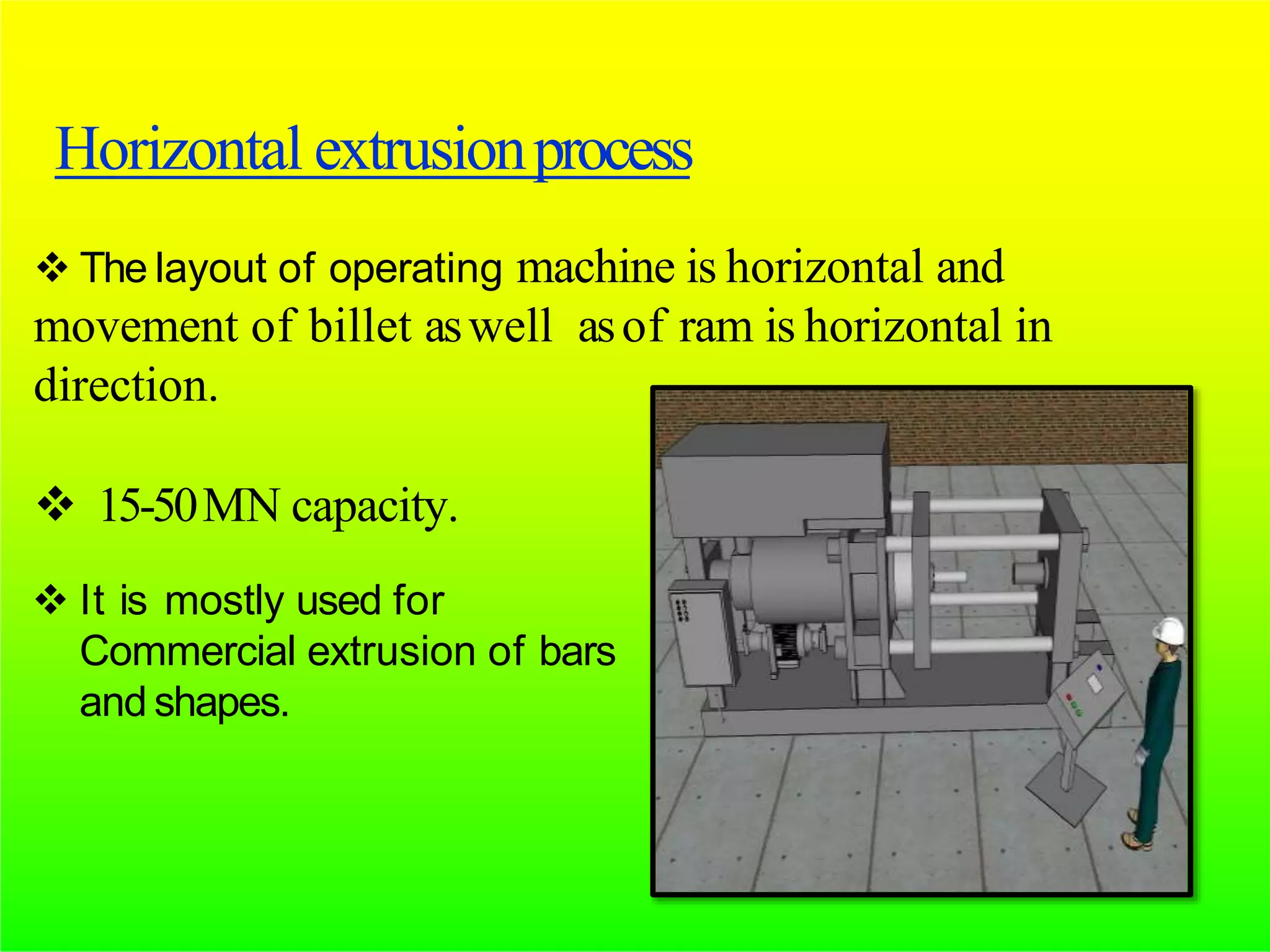

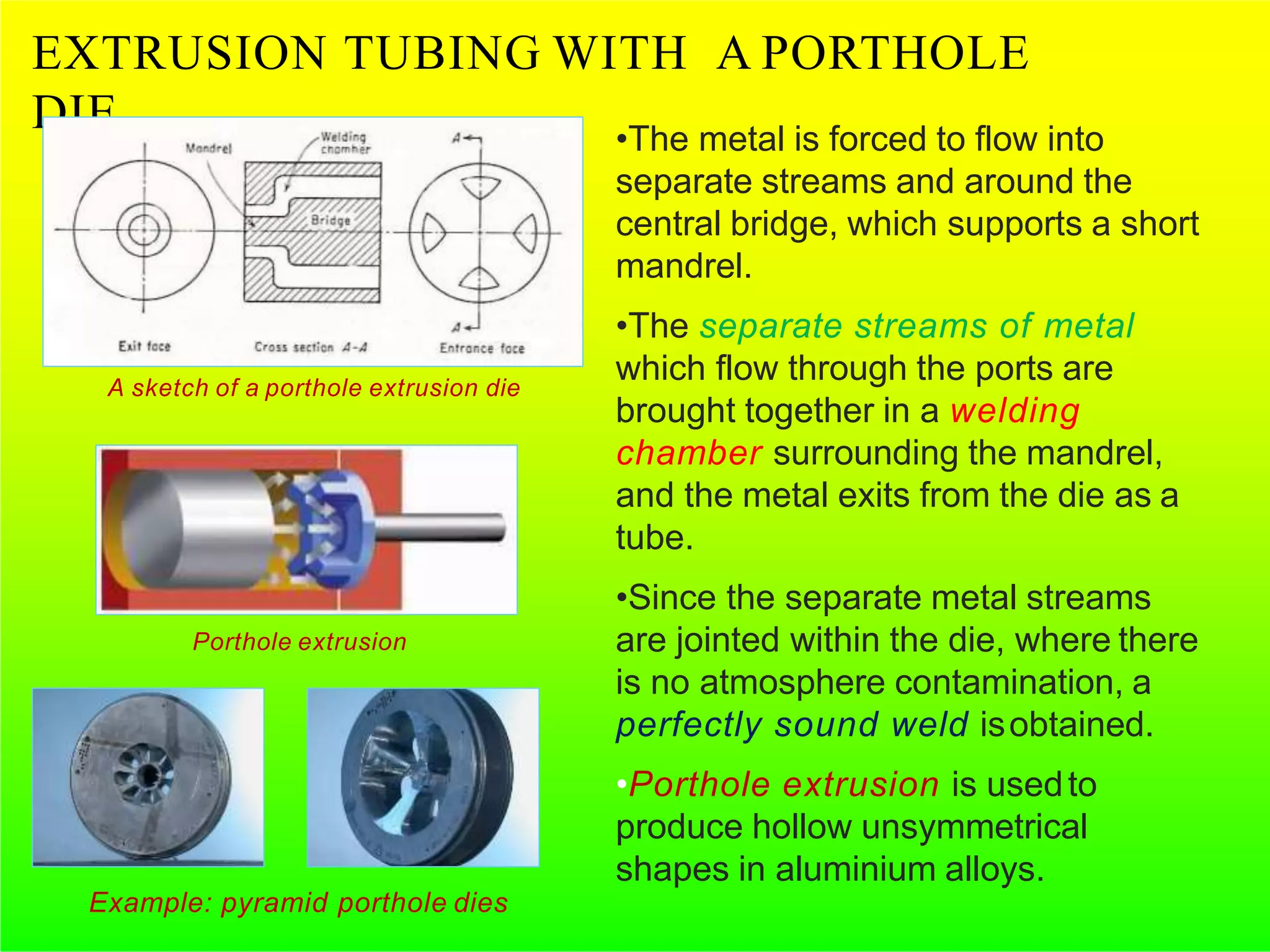

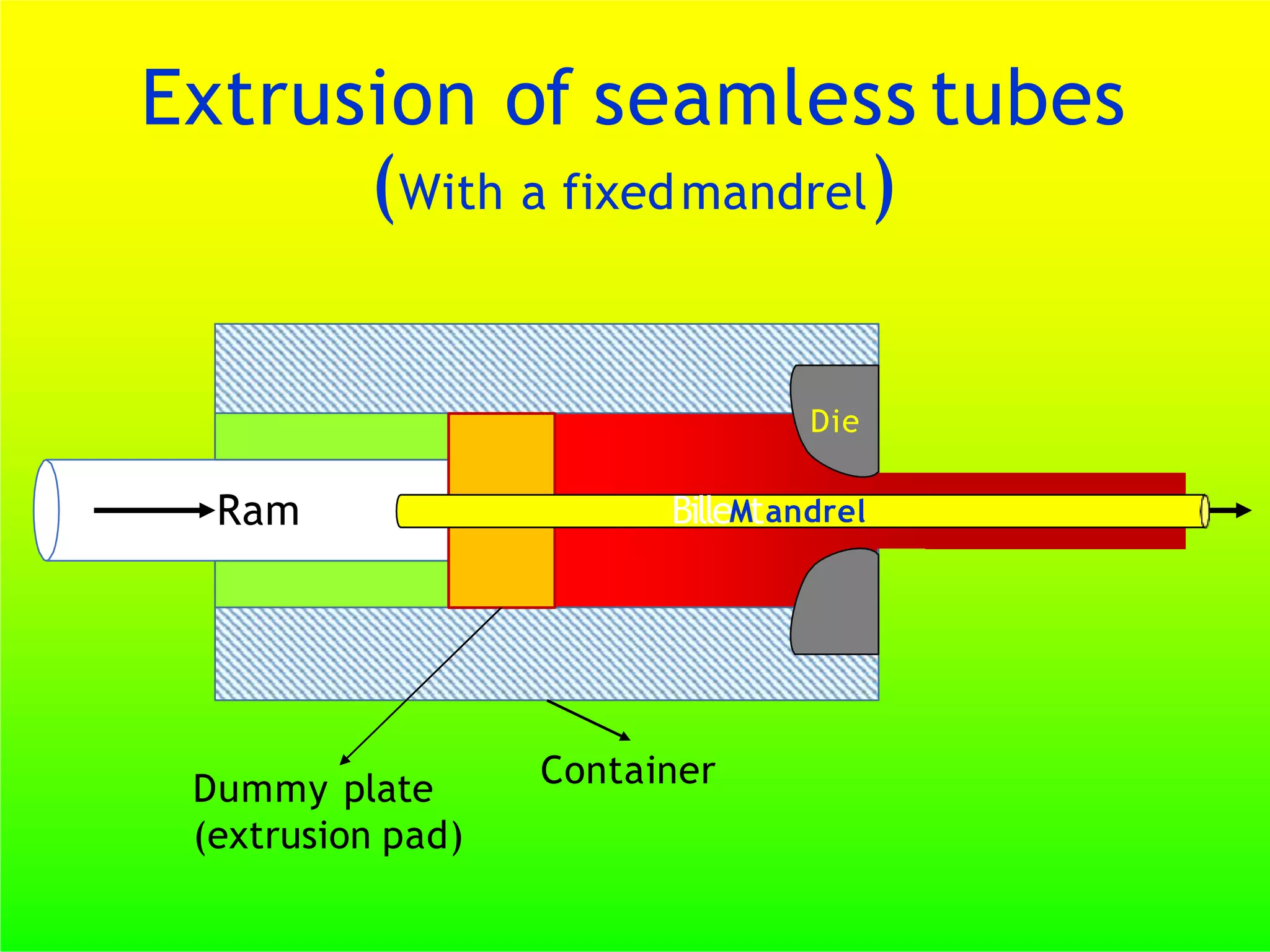

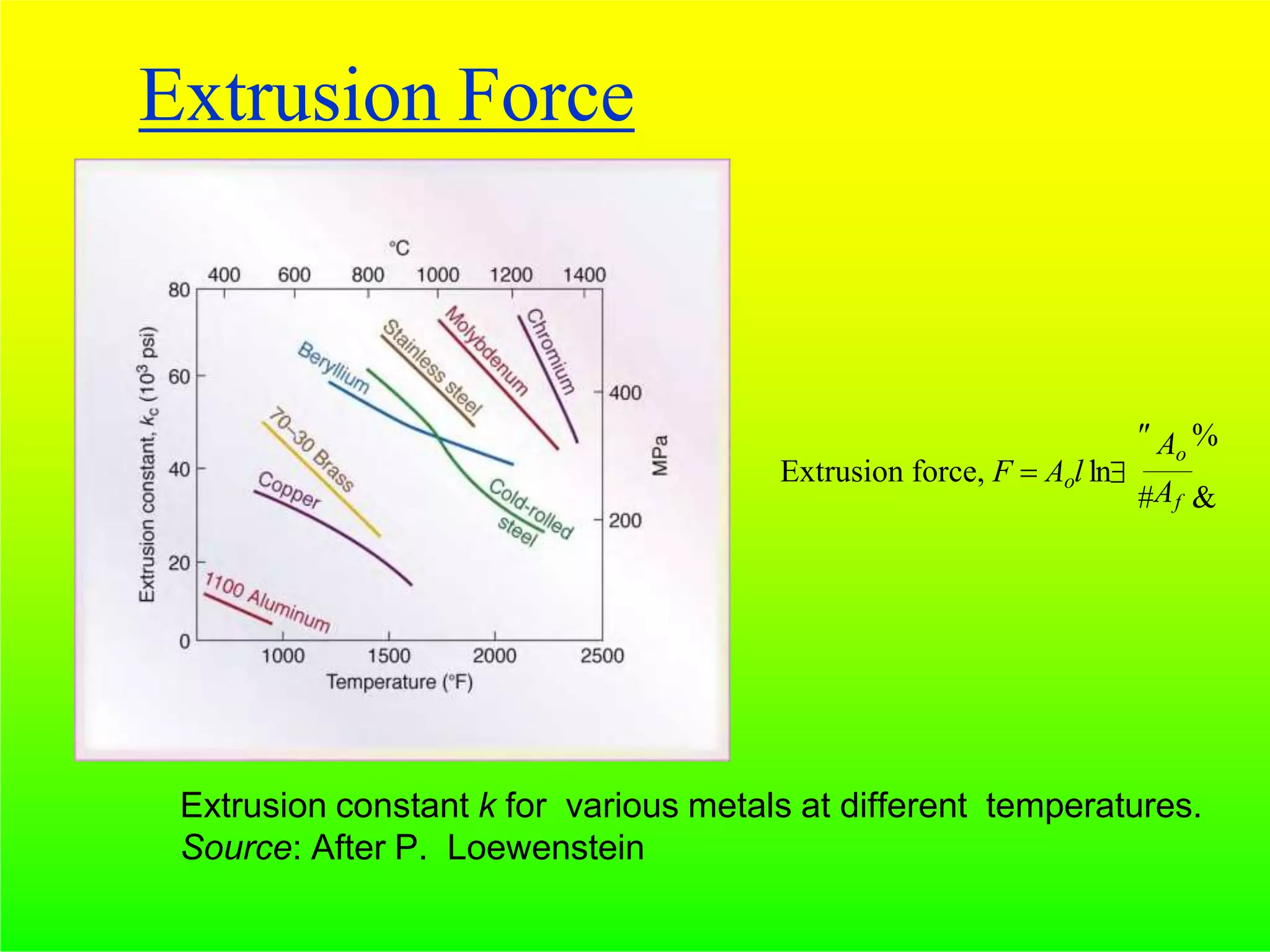

The document provides an overview of the extrusion process for metals. It discusses different types of extrusion including direct/indirect, hot/cold, and hydrostatic extrusion. It also covers extruding tubes and pipes. Key points include:

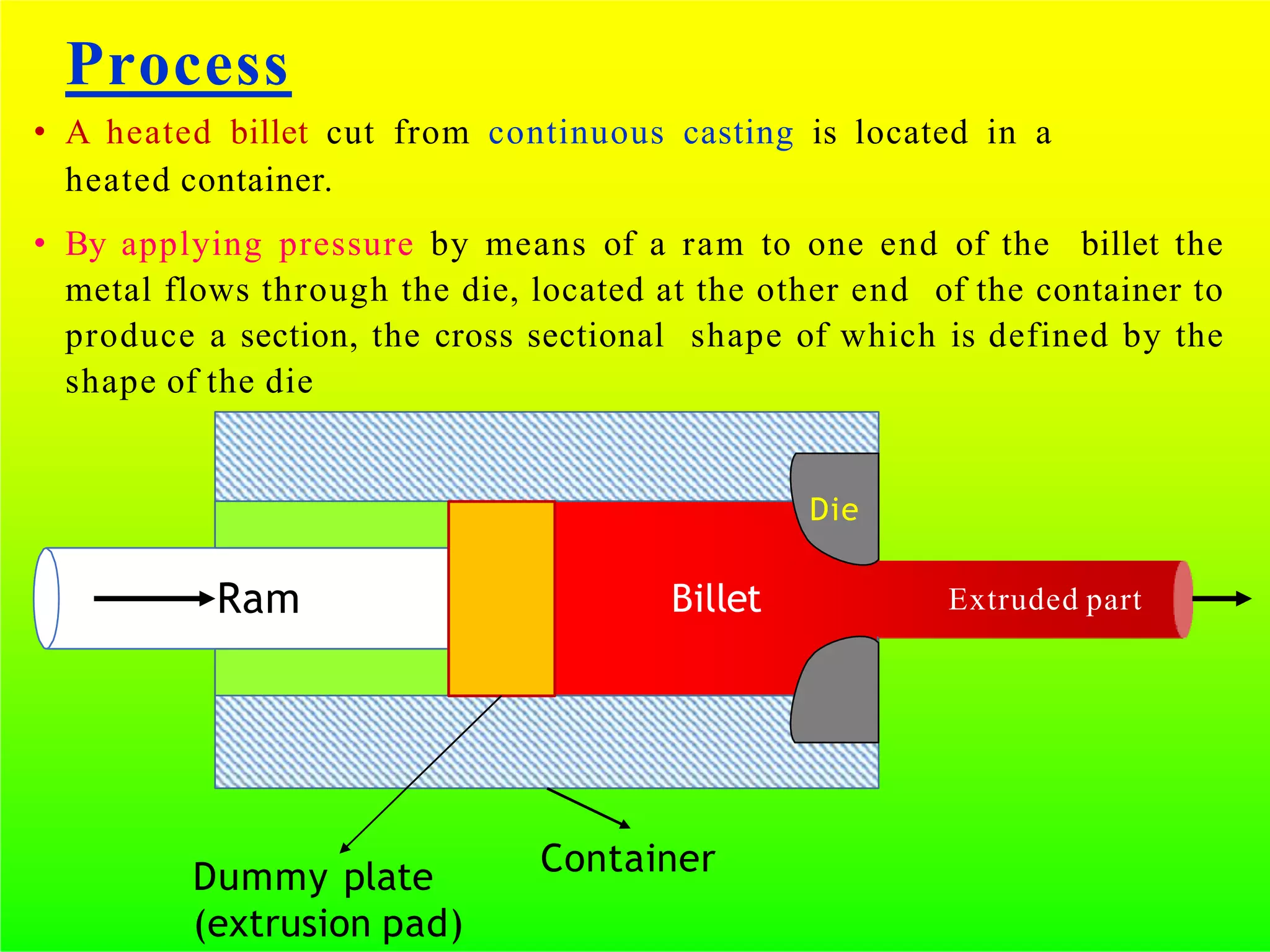

- Extrusion involves pushing heated metal billets through a die to reduce the cross-section and shape the material.

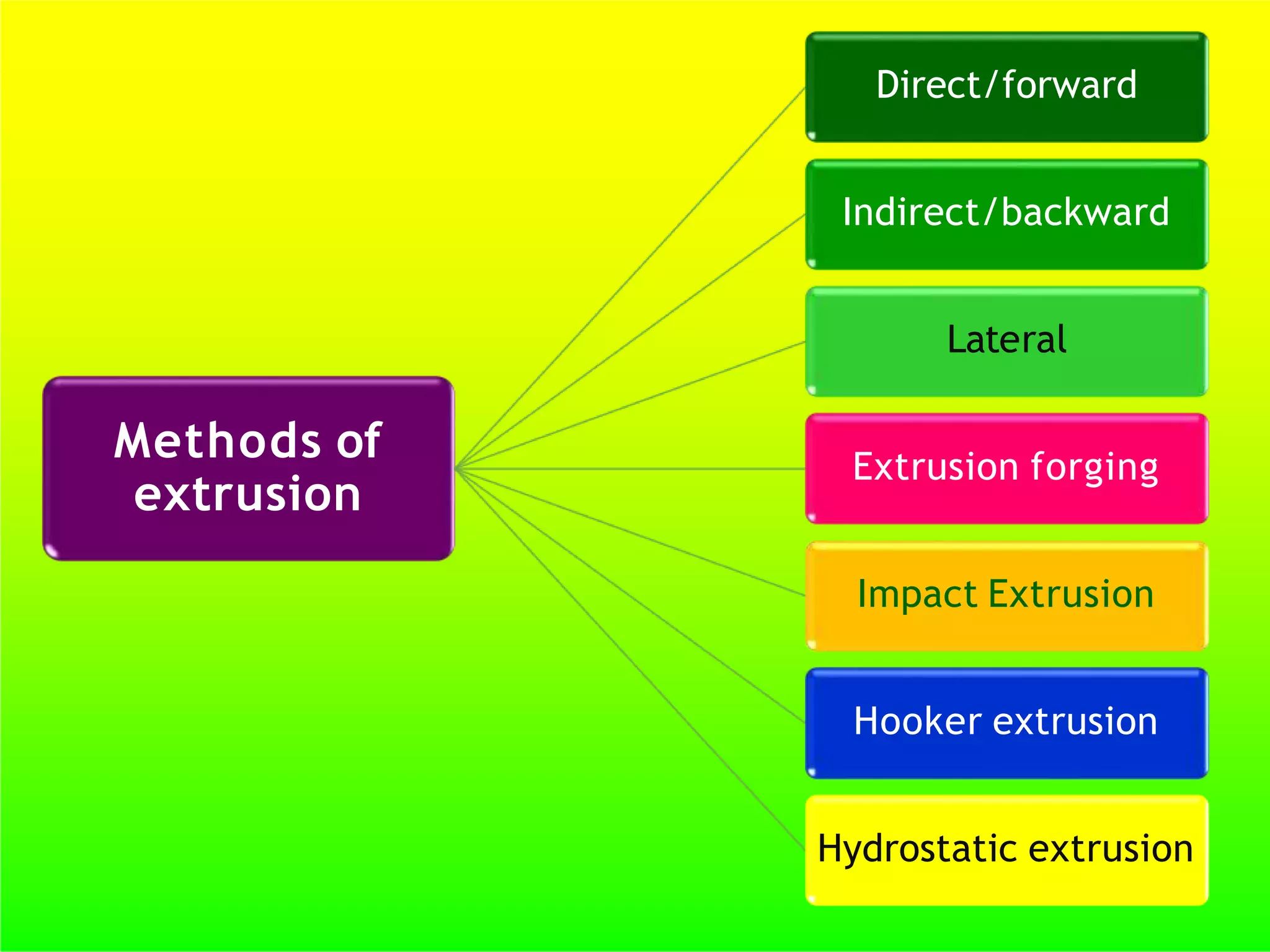

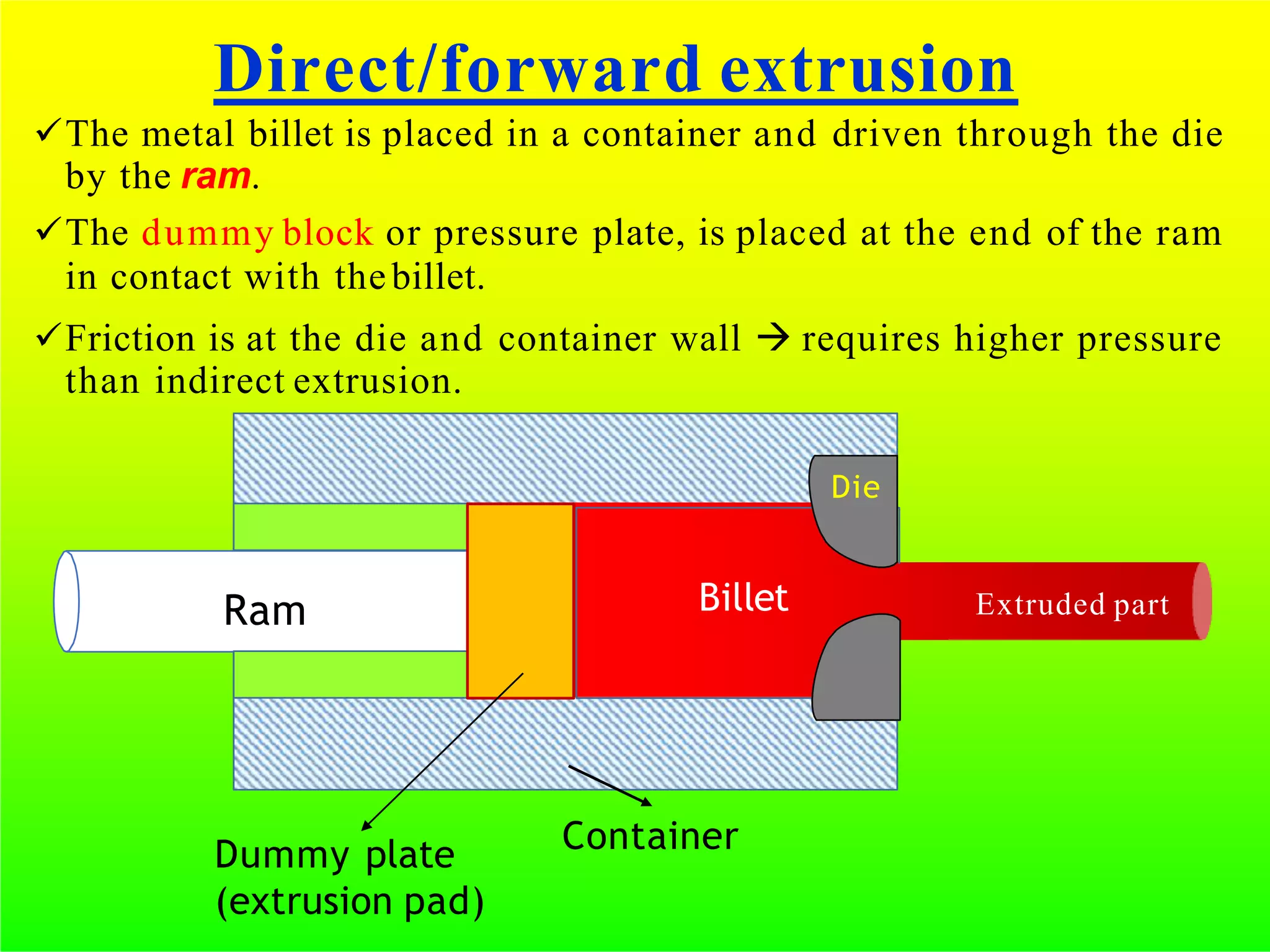

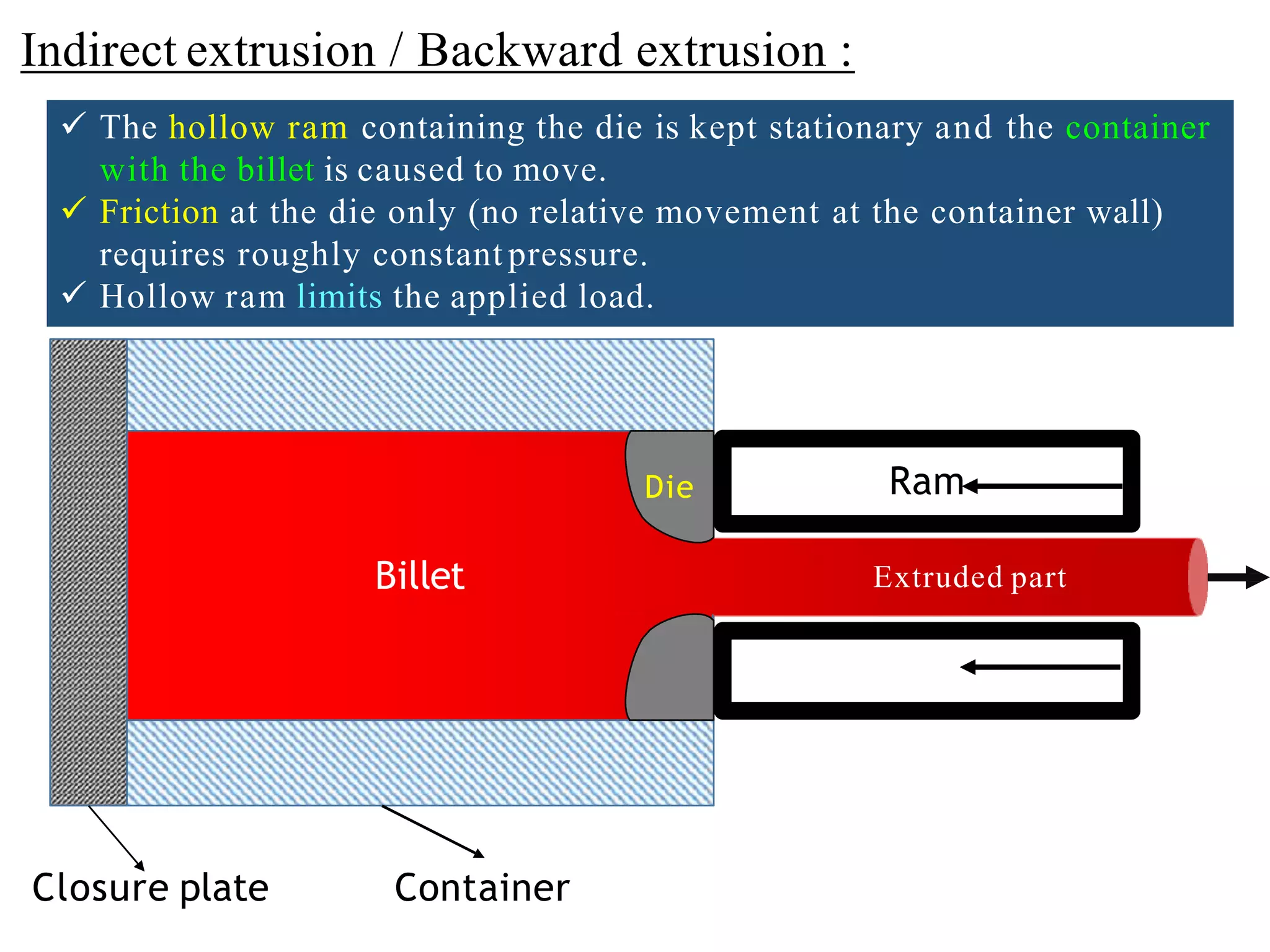

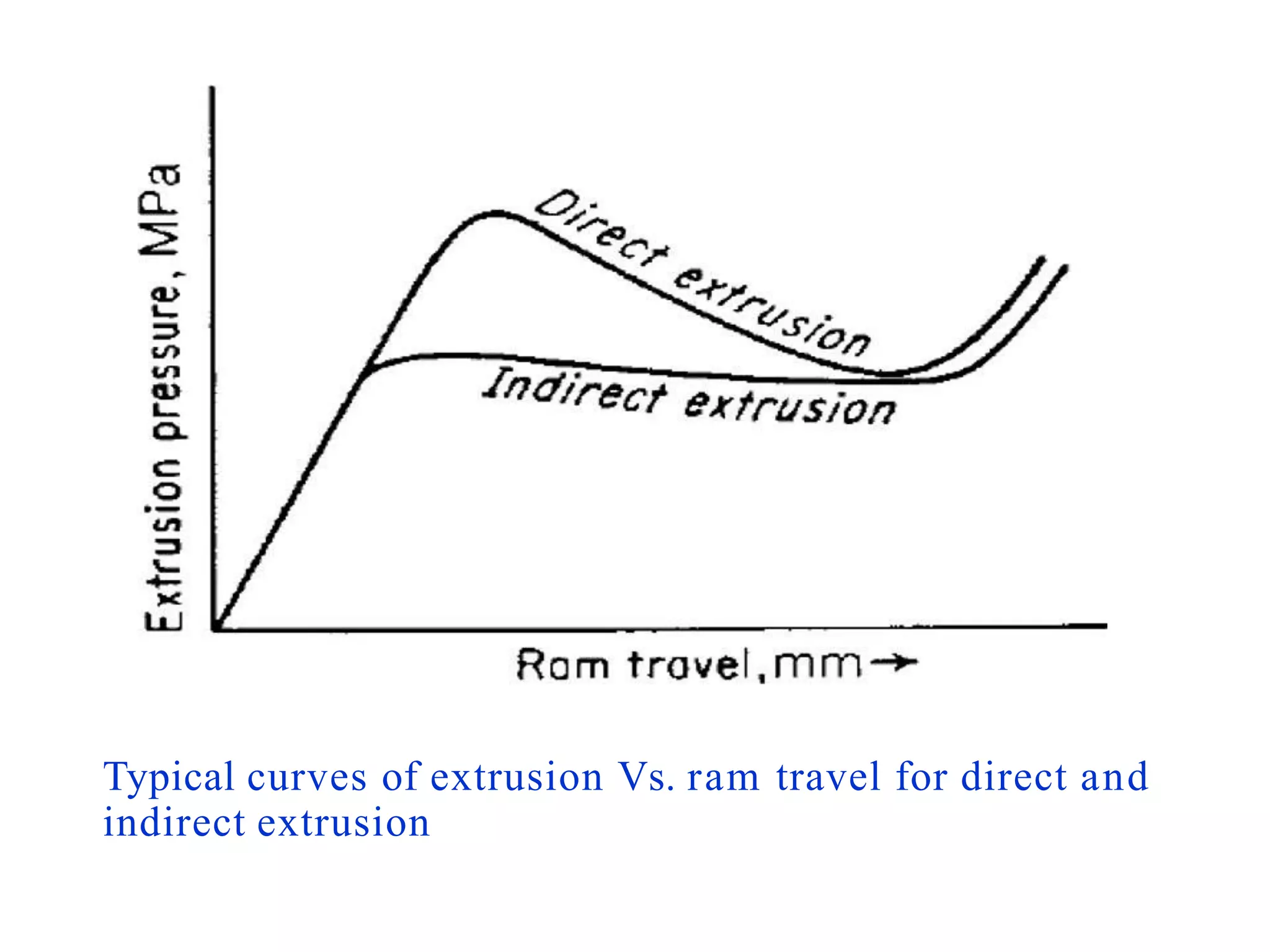

- Direct extrusion uses a stationary container and moving ram, while indirect uses a stationary die and moving container.

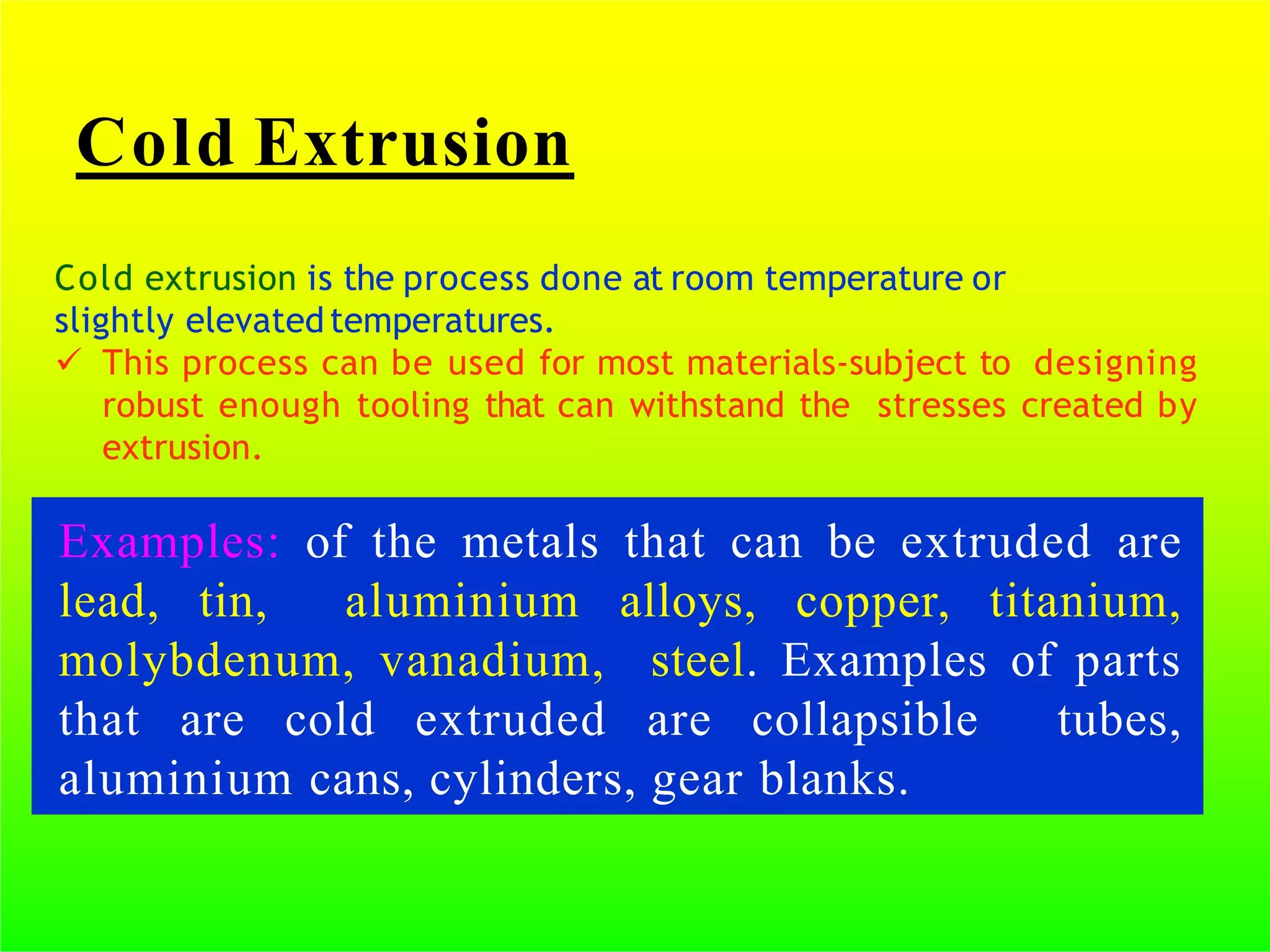

- Hot extrusion is done at 50-75% melting temperature for better formability, while cold extrusion is at or near room temperature.

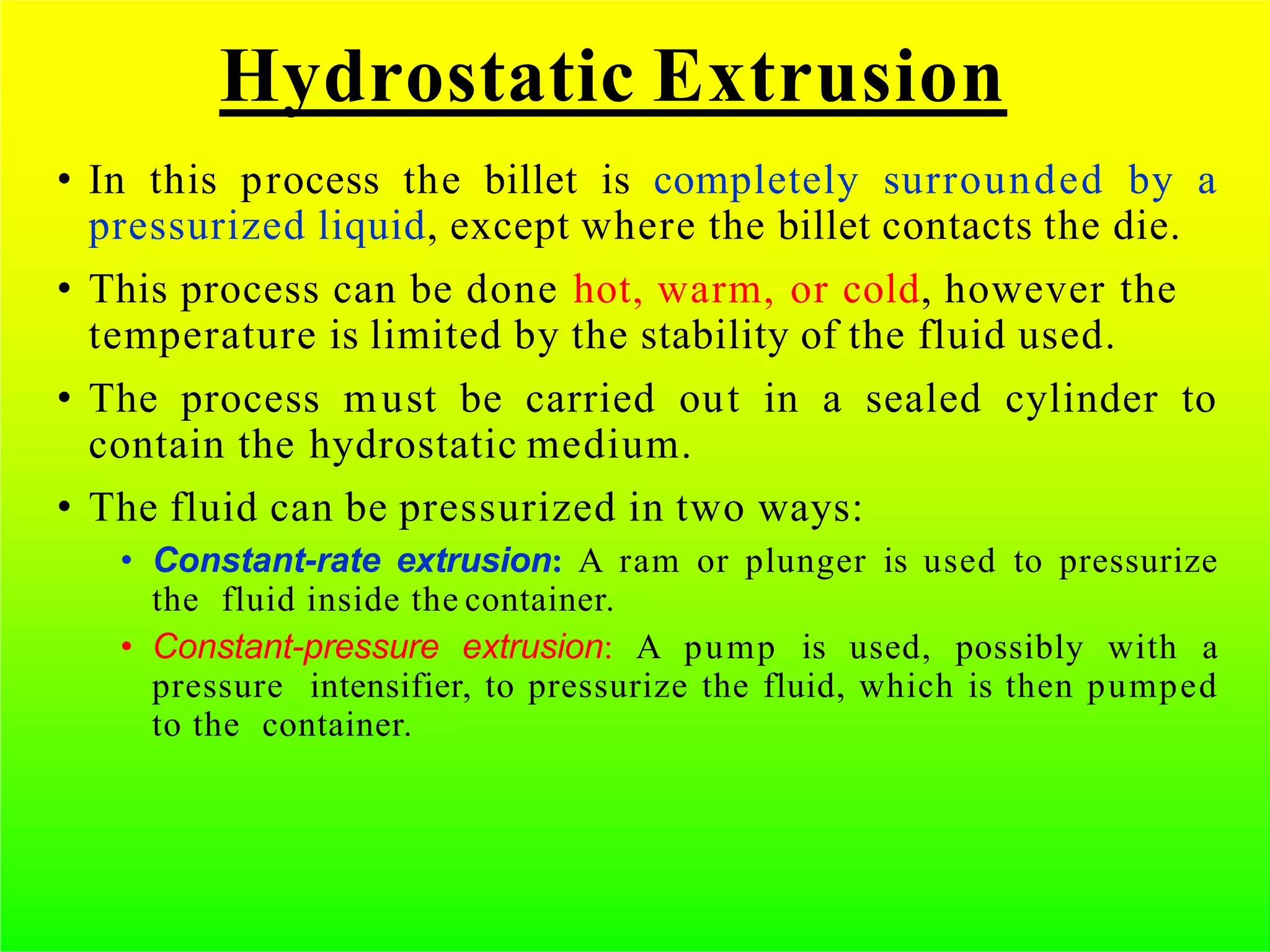

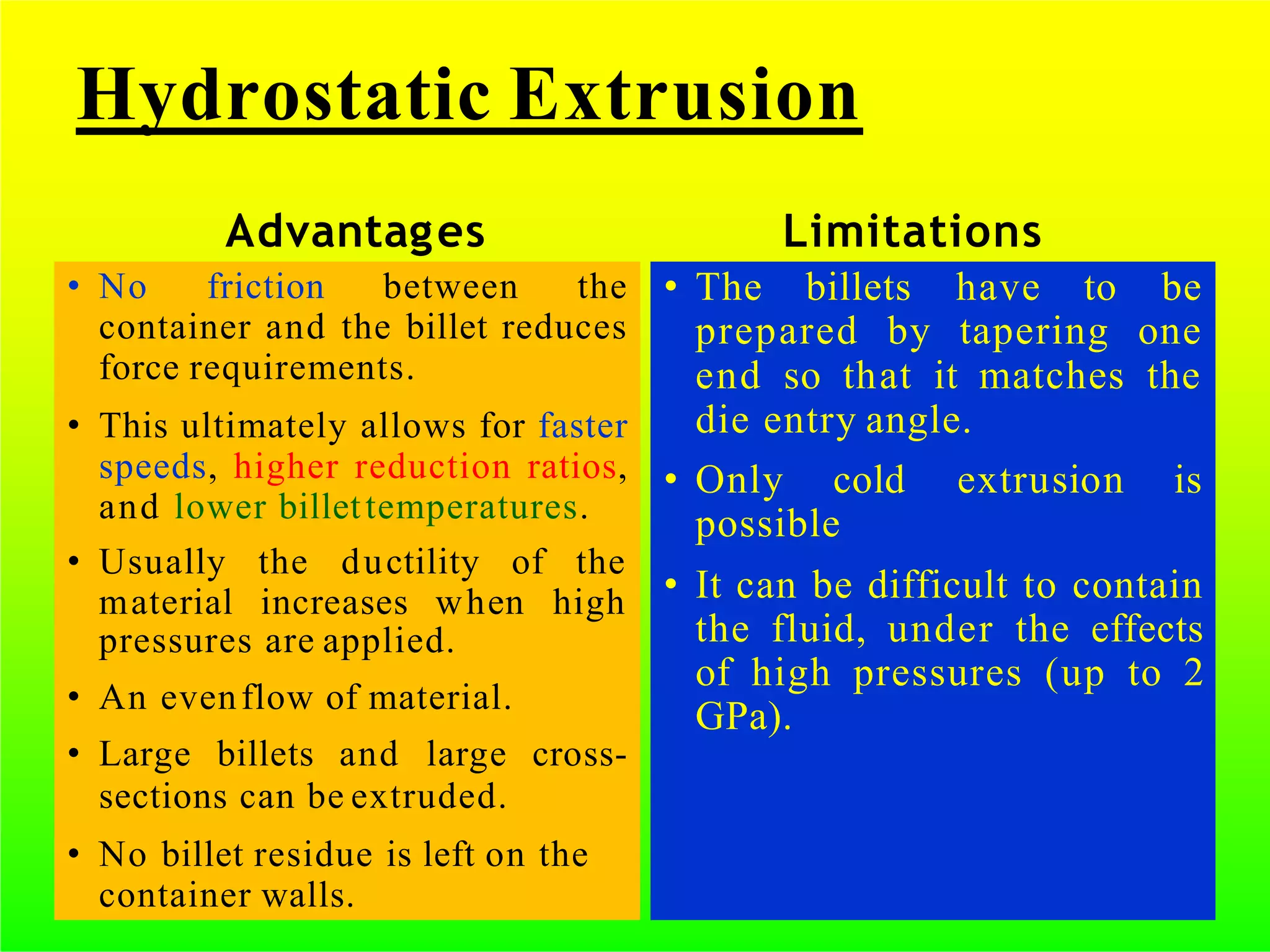

- Hydrostatic extrusion surrounds the billet with pressurized