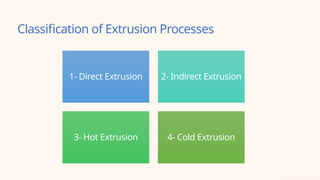

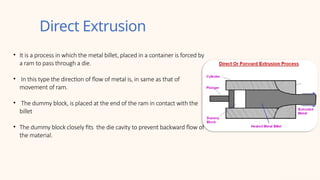

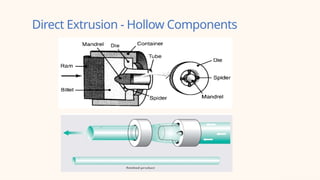

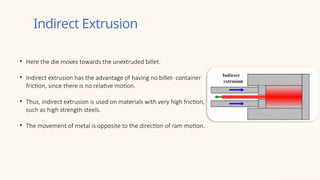

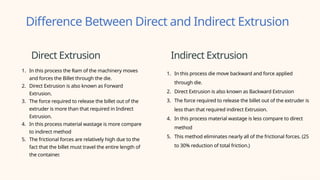

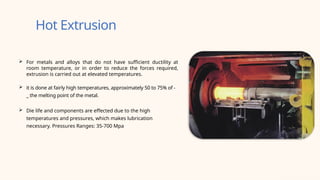

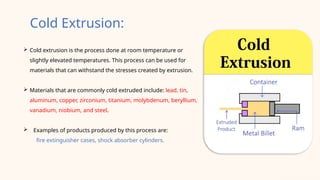

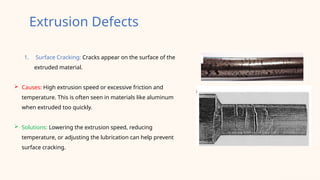

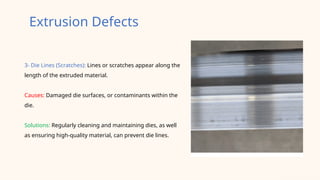

The document discusses the extrusion process, a manufacturing technique for shaping materials by forcing them through a die, with a historical overview dating back to the 18th century and notable developments by Joseph Bramah and Thomas Burr. It covers various types of extrusion methods, including direct and indirect extrusion, as well as hot and cold extrusion, highlighting their differences and applications. Additionally, the document addresses common extrusion defects and the materials used for dies in the process.