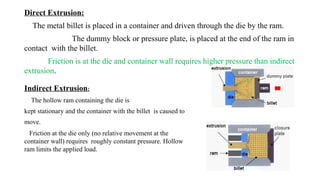

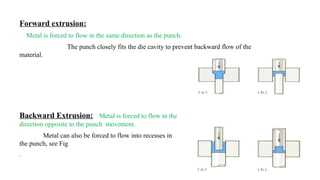

The document discusses the extrusion process. It begins by defining extrusion as forcing a block of metal through a die under high pressure to reduce its cross-section. Extrusion is commonly used to produce cylindrical bars or tubes from metals like aluminum. The document then covers the basic extrusion process, common extrusion products, different types of extrusion processes based on direction and temperature, and key equipment used like presses and dies. It concludes by listing factors that affect the required extrusion force.