This document describes a reciprocating water pump designed to be operated by foot pedals. It contains the following key points:

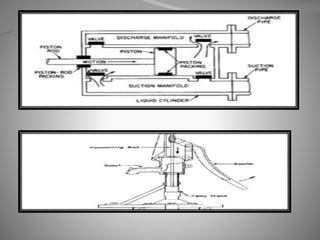

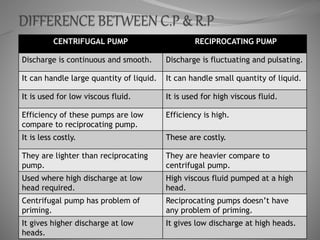

1. The pump uses a reciprocating mechanism powered by foot pedals to lift water from a depth of up to 7 meters, providing an efficient alternative to hand pumps.

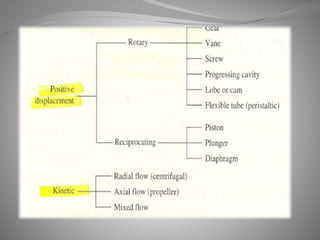

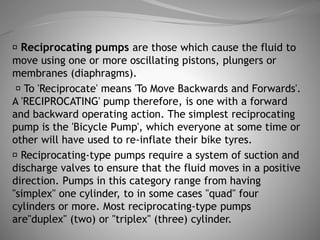

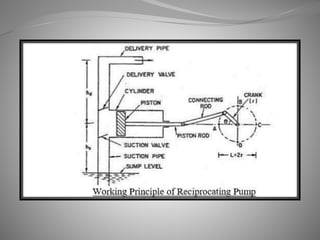

2. Reciprocating pumps are described as having oscillating pistons or plungers that move water in a positive direction through inlet and outlet valves.

3. The pedal-powered reciprocating pump is compact, portable, requires no electricity, and is low-cost making it suitable for rural applications to lift water without heavy lifting or electrical power.