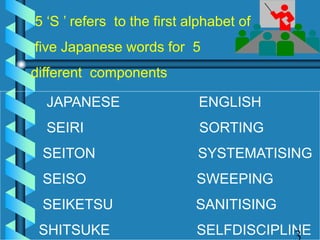

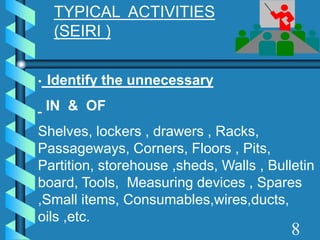

This document provides an overview of the 5S methodology, which consists of five Japanese words that each represent an element of workplace organization and standardization: Seiri (Sorting), Seiton (Systematizing), Seiso (Sweeping), Seiketsu (Sanitizing), and Shitsuke (Self-Discipline). It describes each element in detail, explaining the goals and typical activities. Maintaining 5S standards helps create a cleaner, safer, more productive work environment through visual controls and strict organization of tools and equipment.