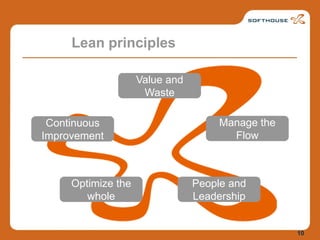

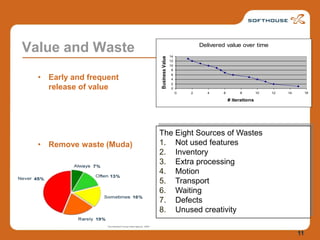

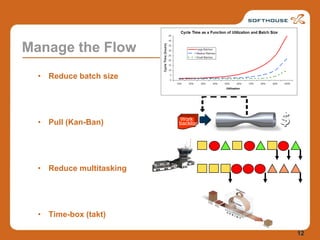

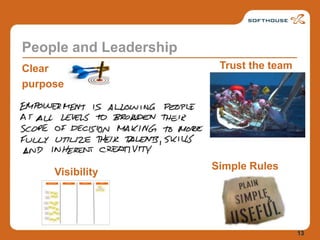

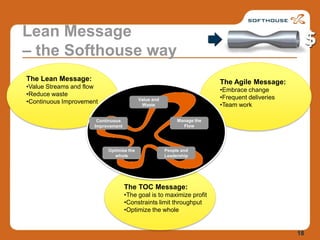

Anders Sixtensson, an expert with over 20 years of experience in business consultancy, aims to enhance understanding of lean and agile principles in a workshop setting for Company X. The agenda includes discussions on the current state of lean practices, group discussions on practical examples, and a focus on continuous improvement and waste reduction. The session is designed to inspire participants to adopt lean methodologies in their daily operations.