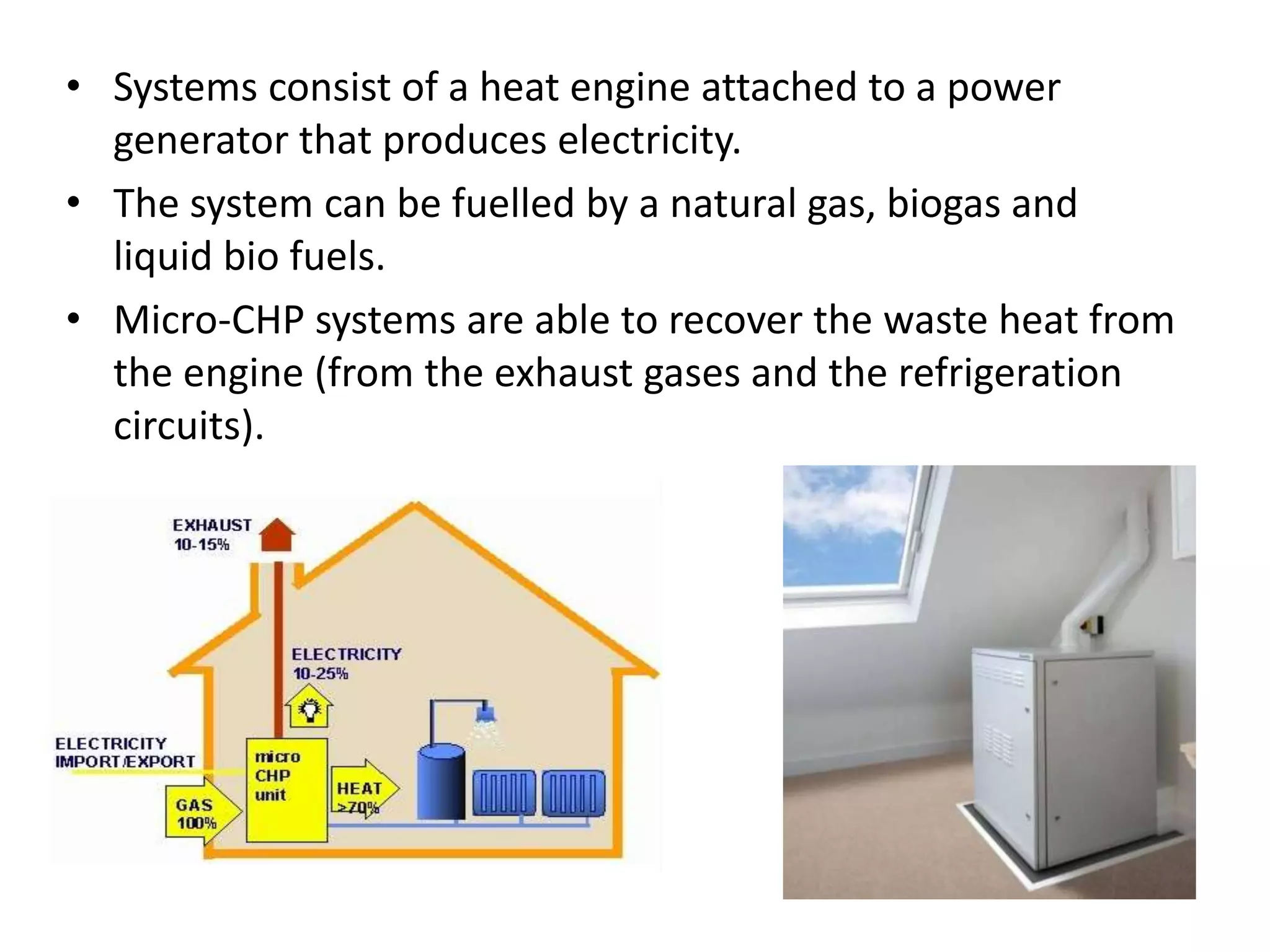

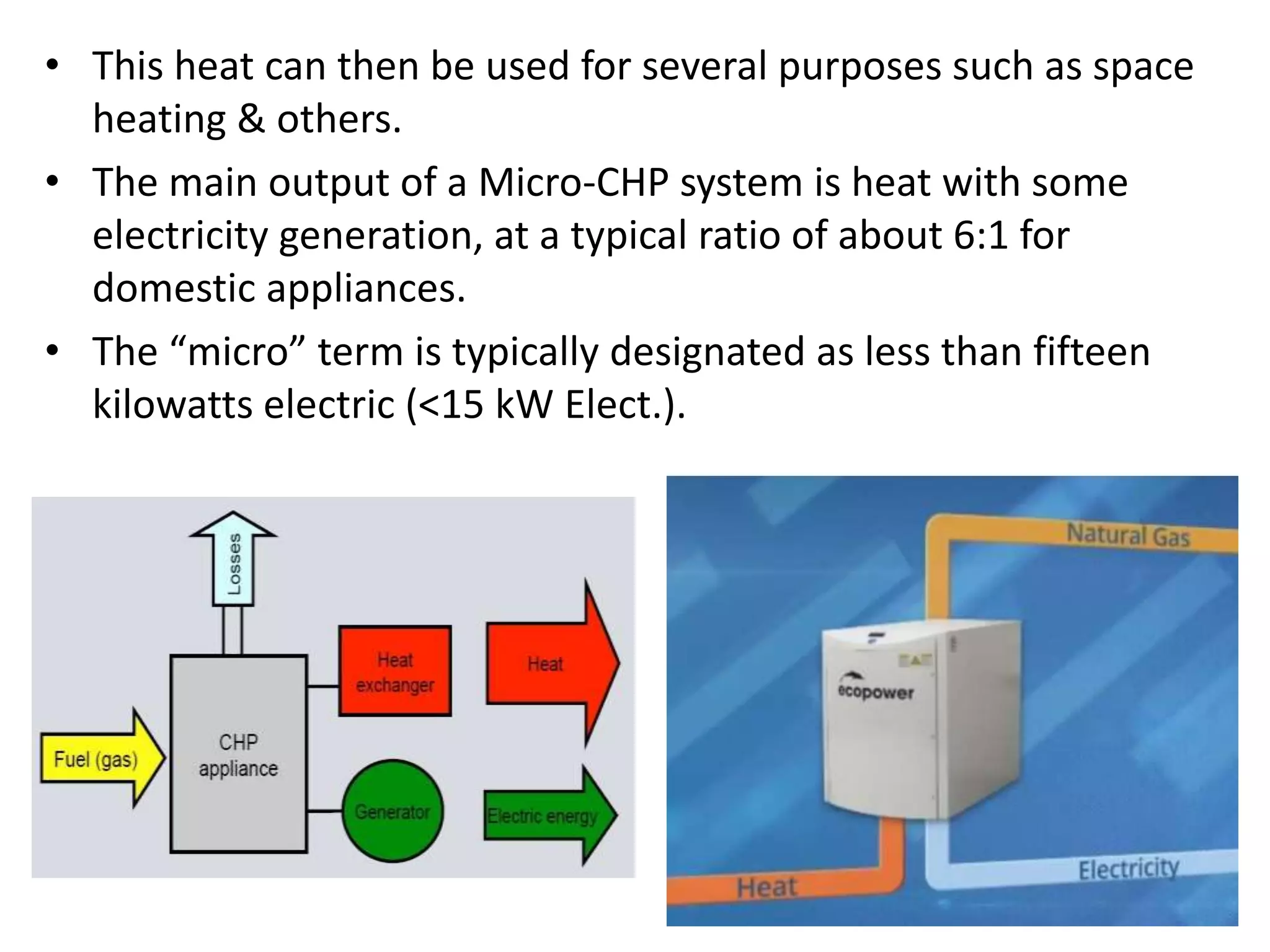

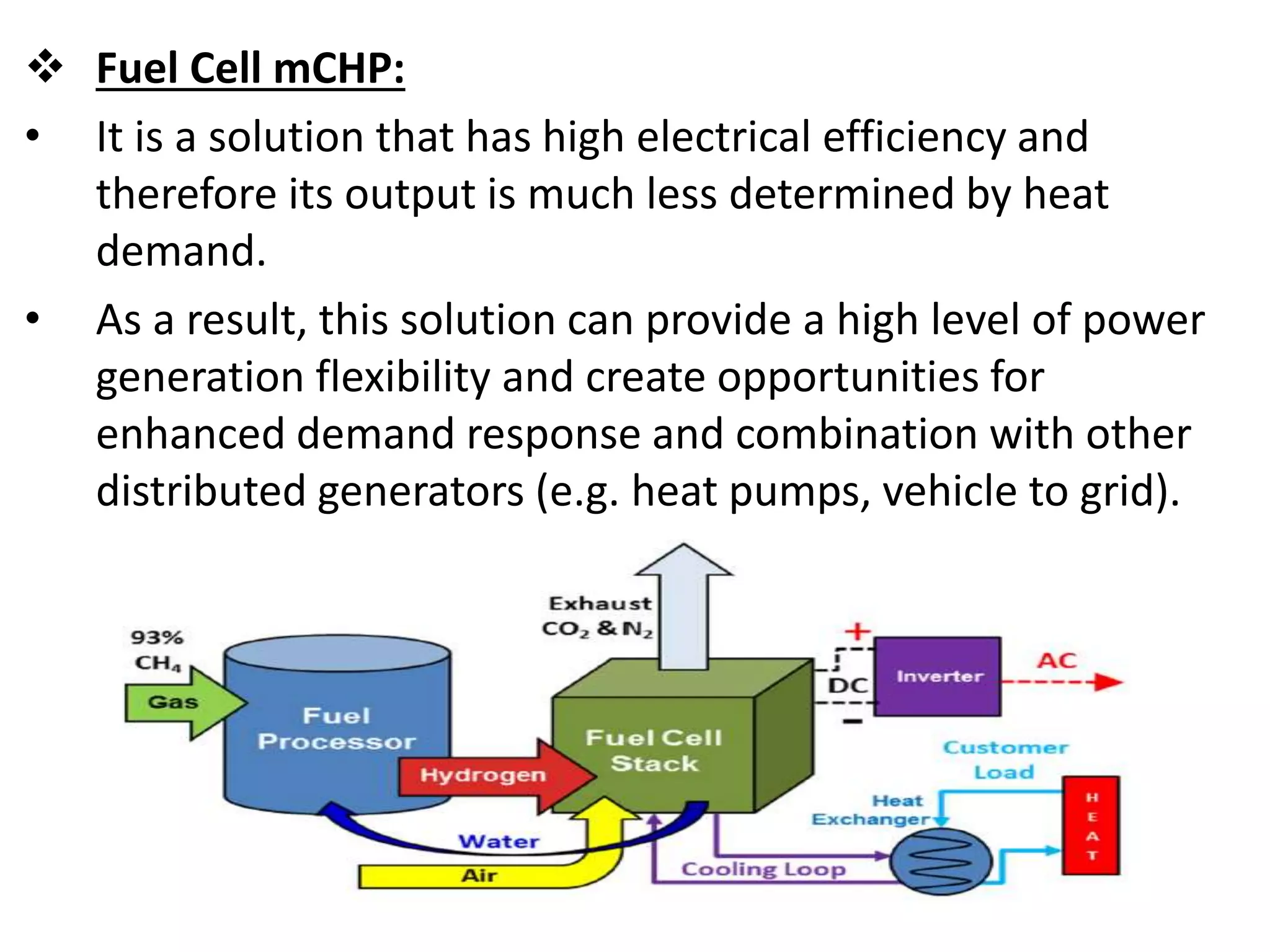

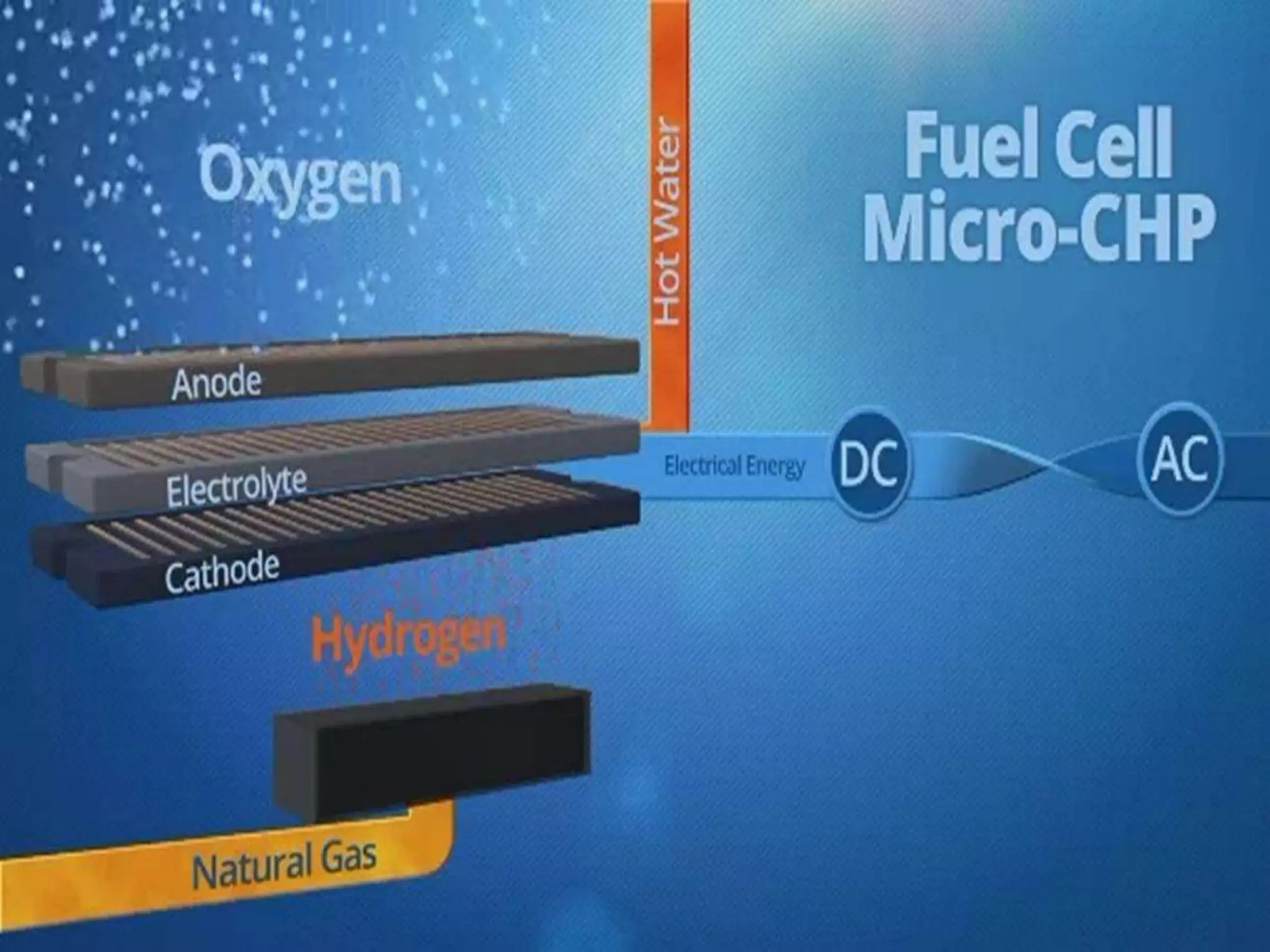

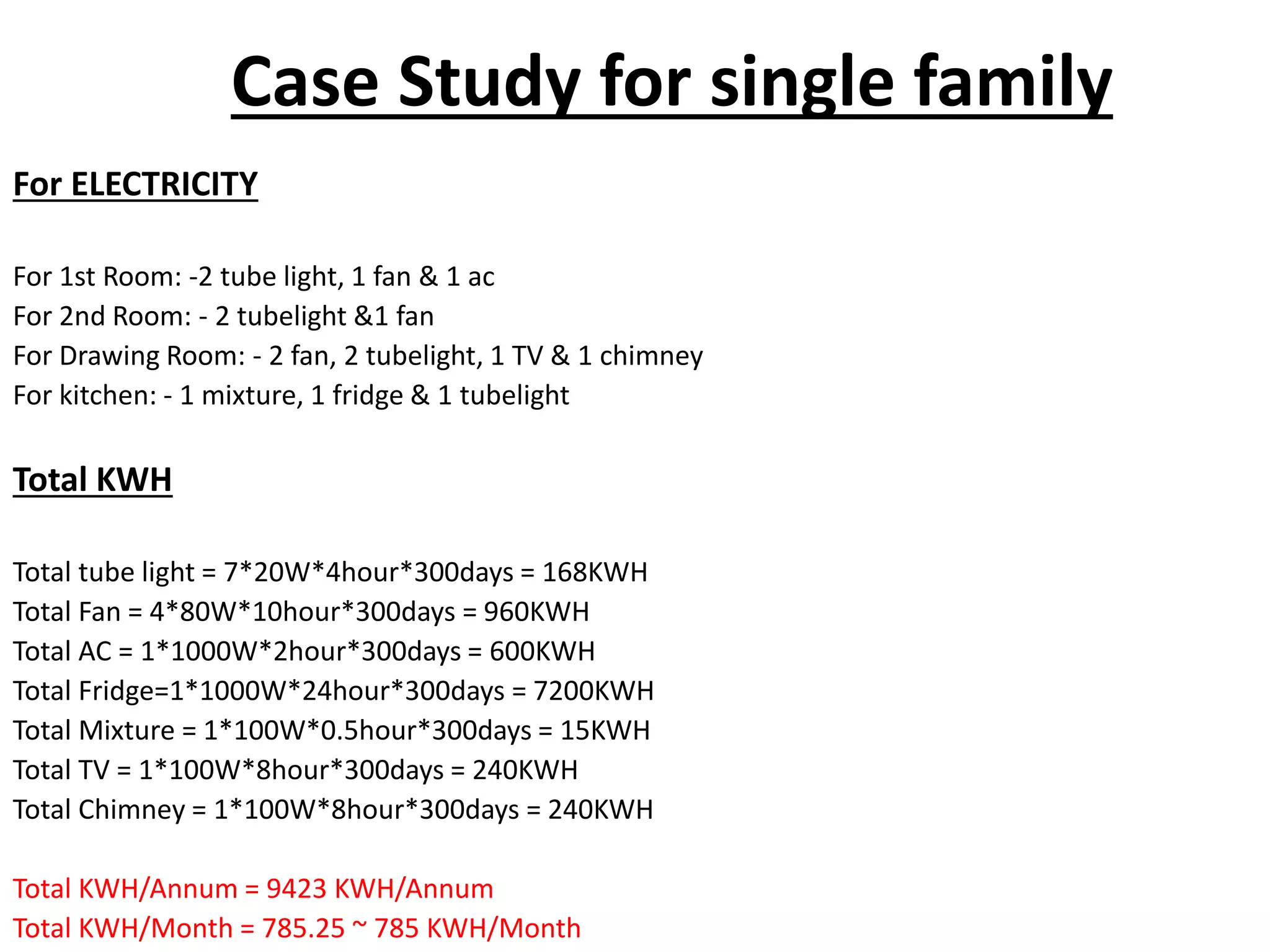

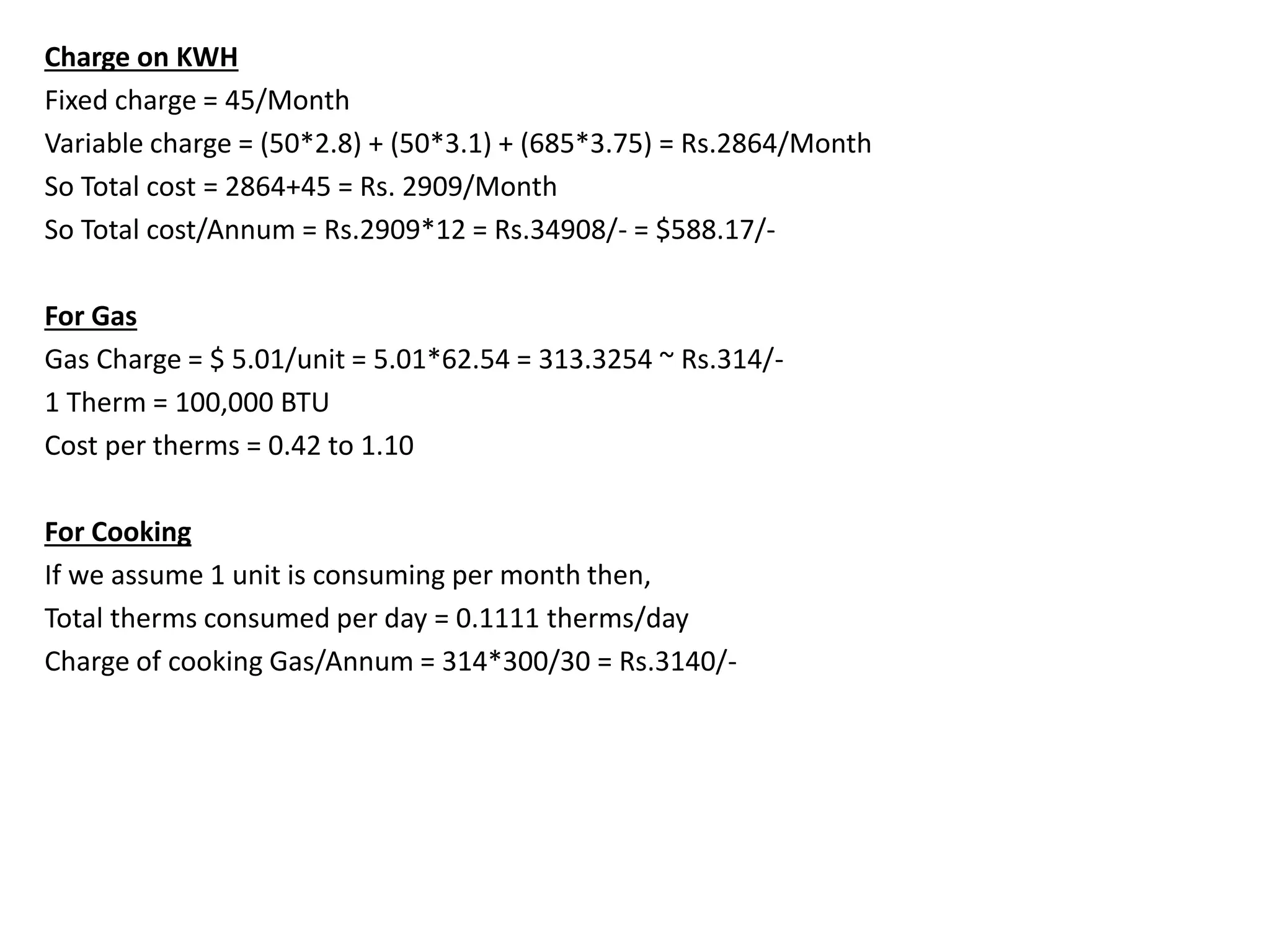

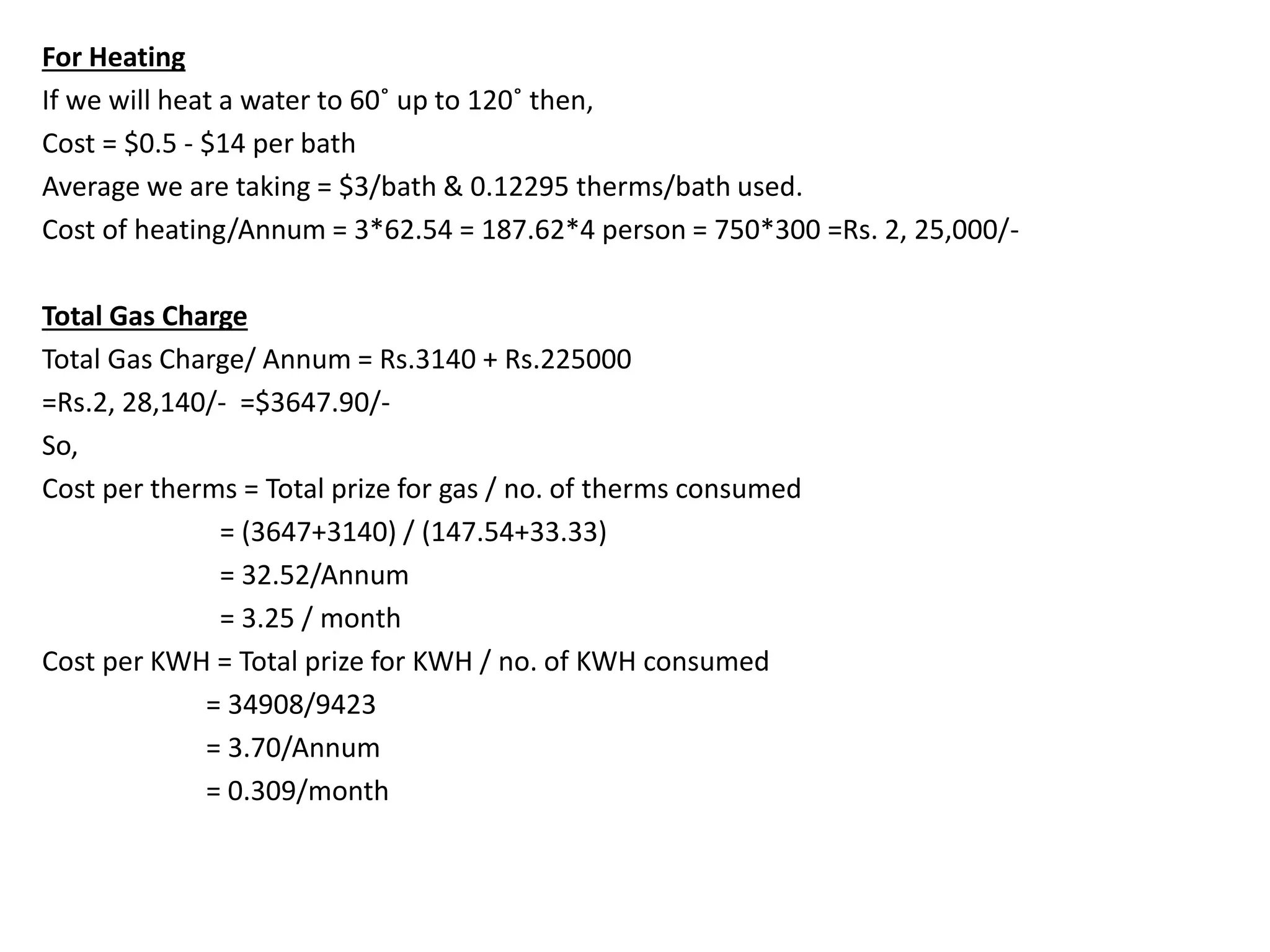

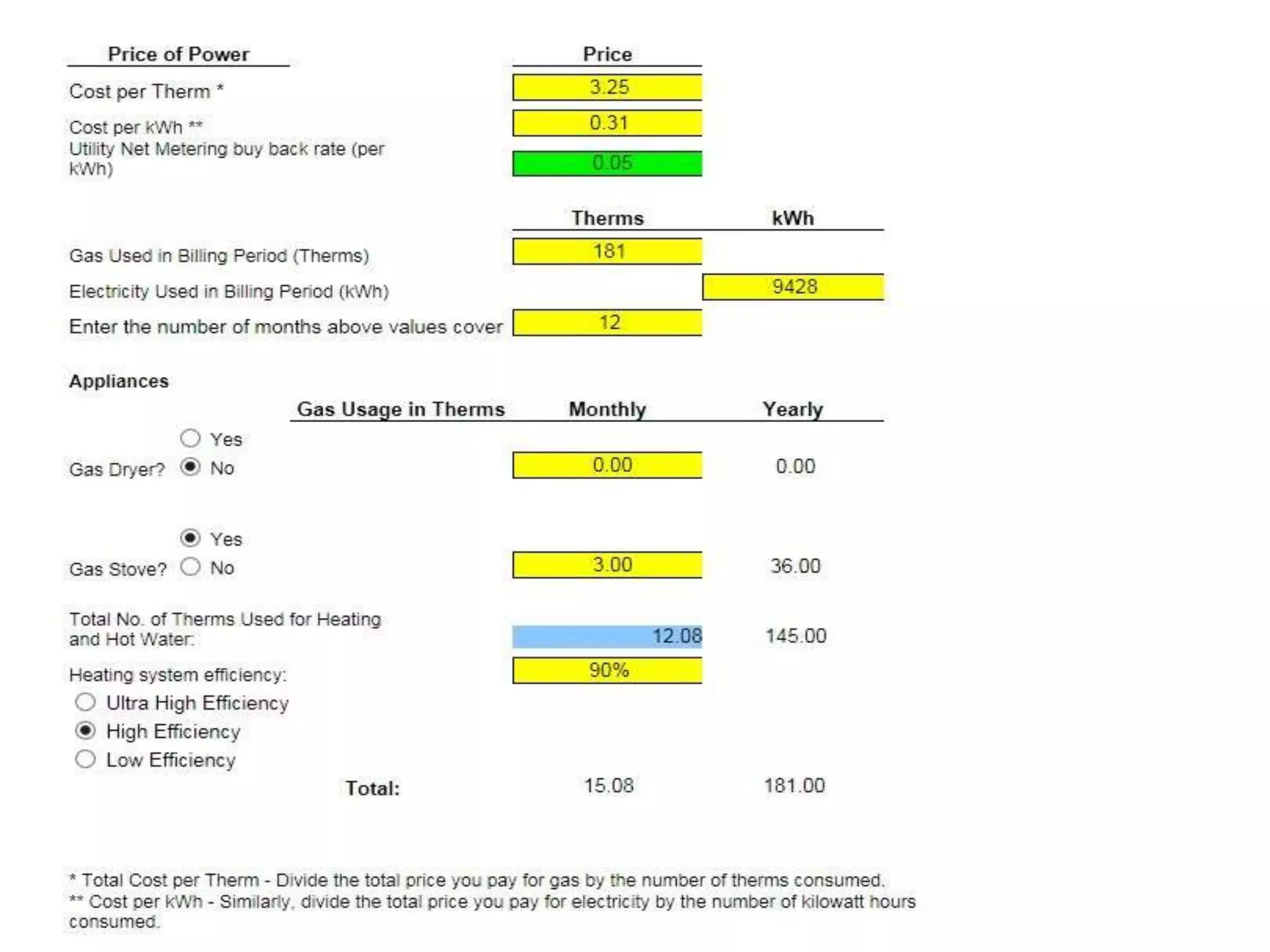

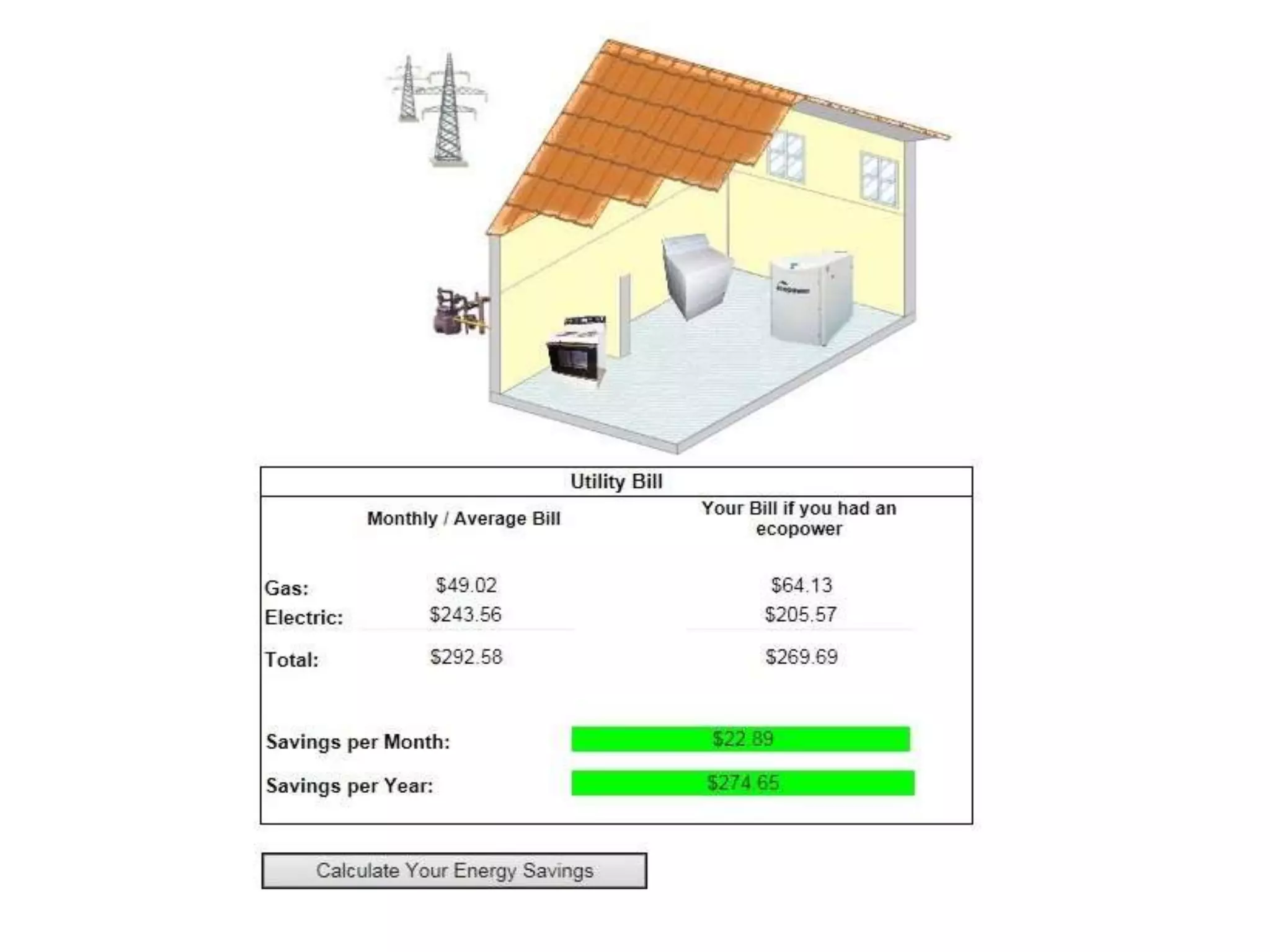

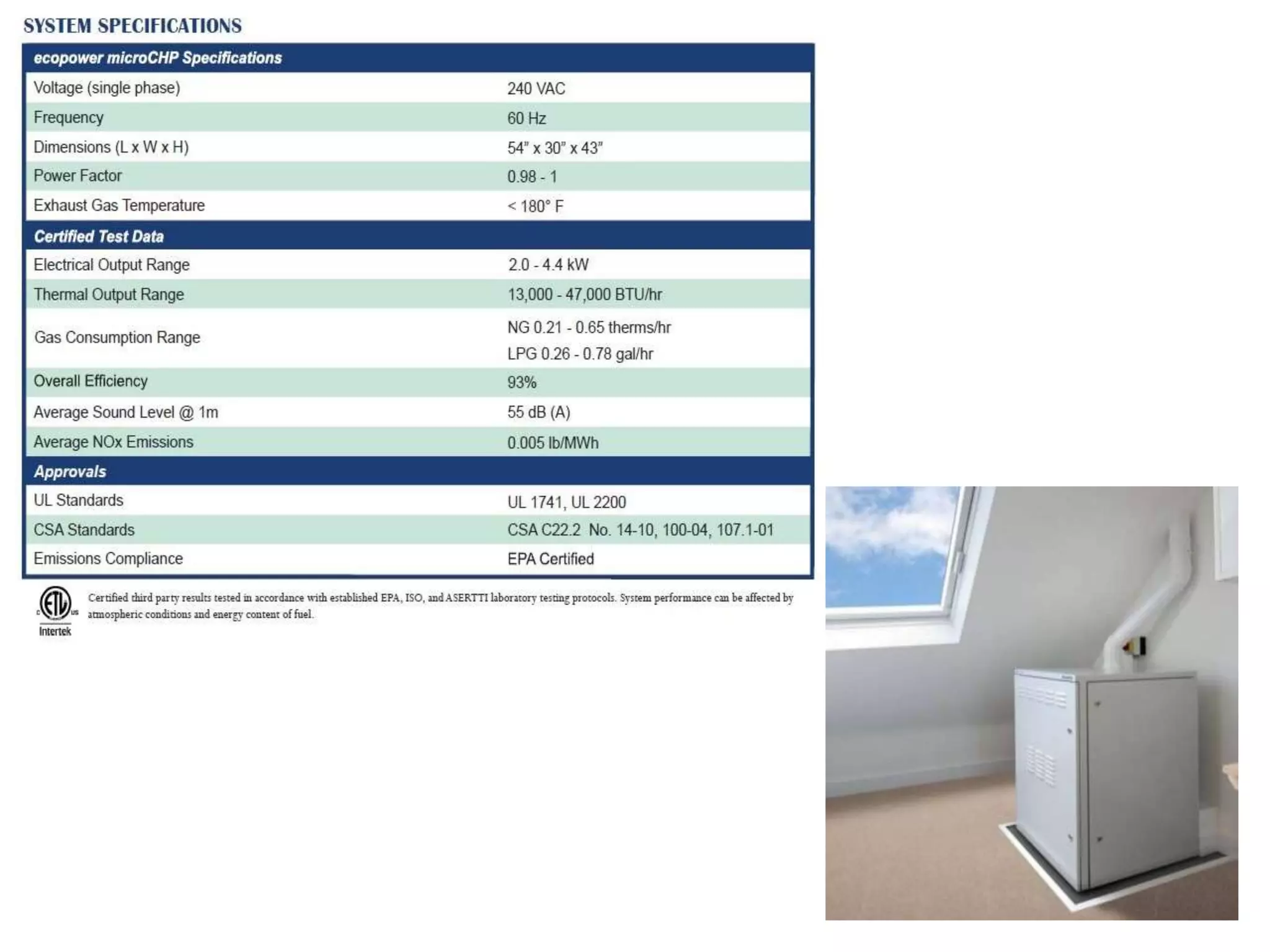

Micro combined heat and power (micro CHP) simultaneously generates electricity and usable heat from a single fuel source. It provides environmental, economic and social benefits. Micro CHP systems are typically under 15 kW and use natural gas, biogas or liquid biofuels. They capture waste heat from power generation to heat spaces and water. Compared to separate electricity and heating systems, micro CHP can achieve over 70% total fuel efficiency. It offers savings on energy costs and reduced emissions. Fuel cell and internal combustion engine micro CHP are well suited to residential and small commercial applications.