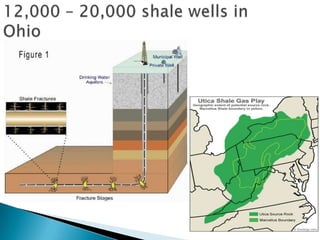

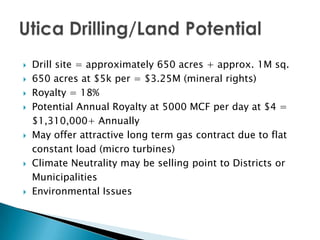

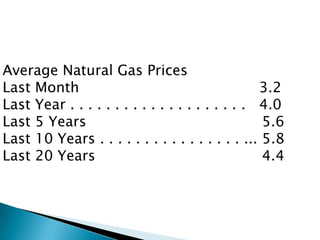

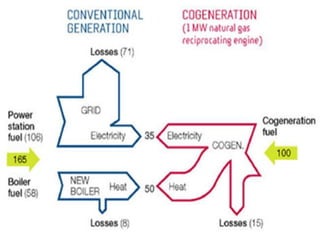

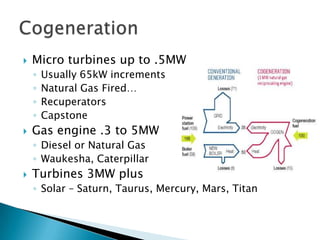

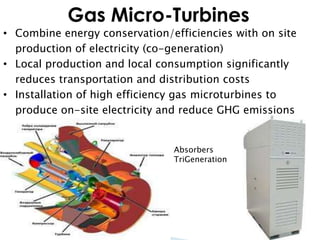

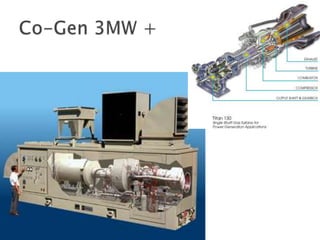

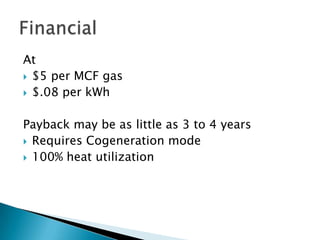

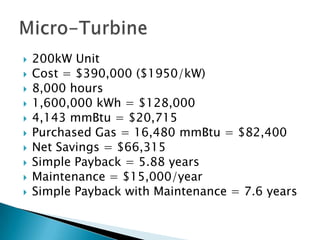

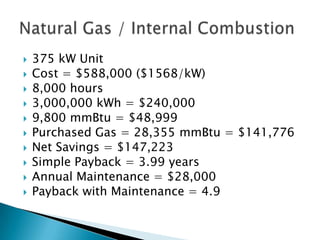

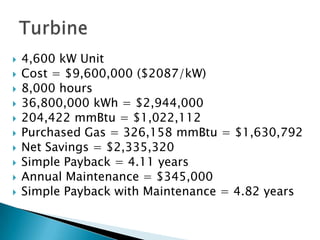

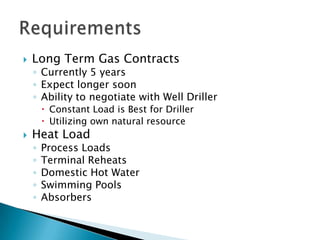

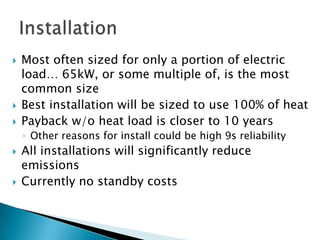

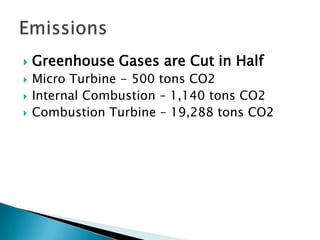

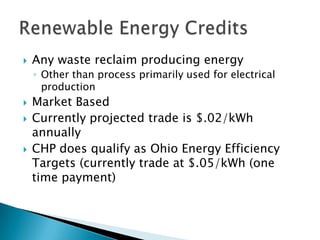

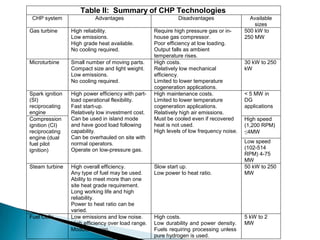

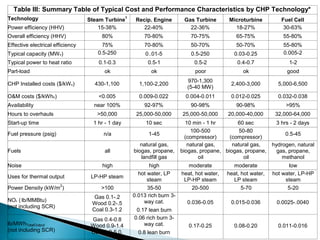

The document discusses the economic and environmental potential of the Utica Shale natural gas reserves in Ohio, highlighting job creation and energy independence benefits. It explores various natural gas applications, like micro-turbines and co-generation, and provides financial examples for installing gas-fired systems with associated payback periods. It underlines the advantages of natural gas vehicles and infrastructure while noting environmental impacts and technological specifics of different cogeneration technologies.