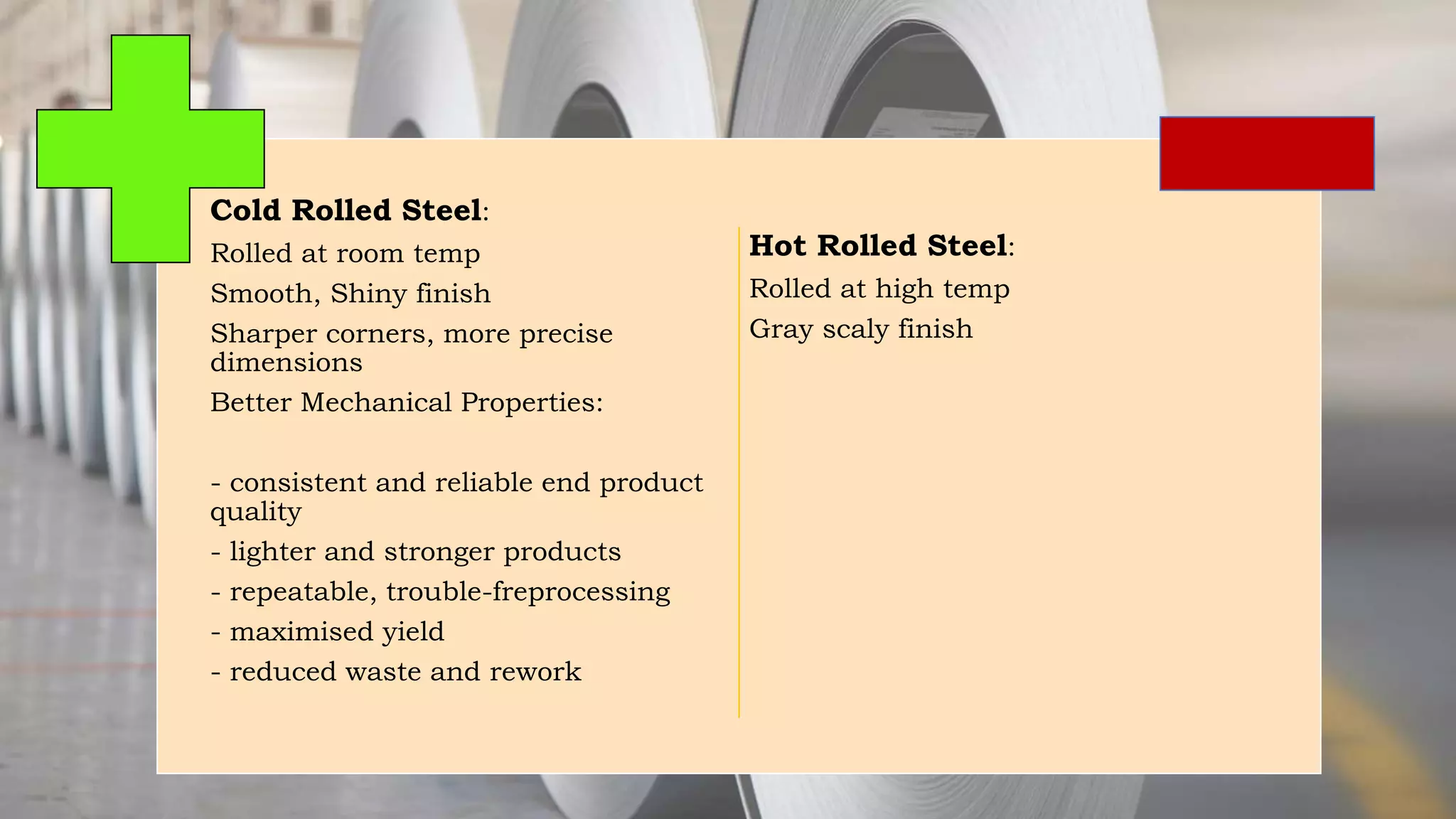

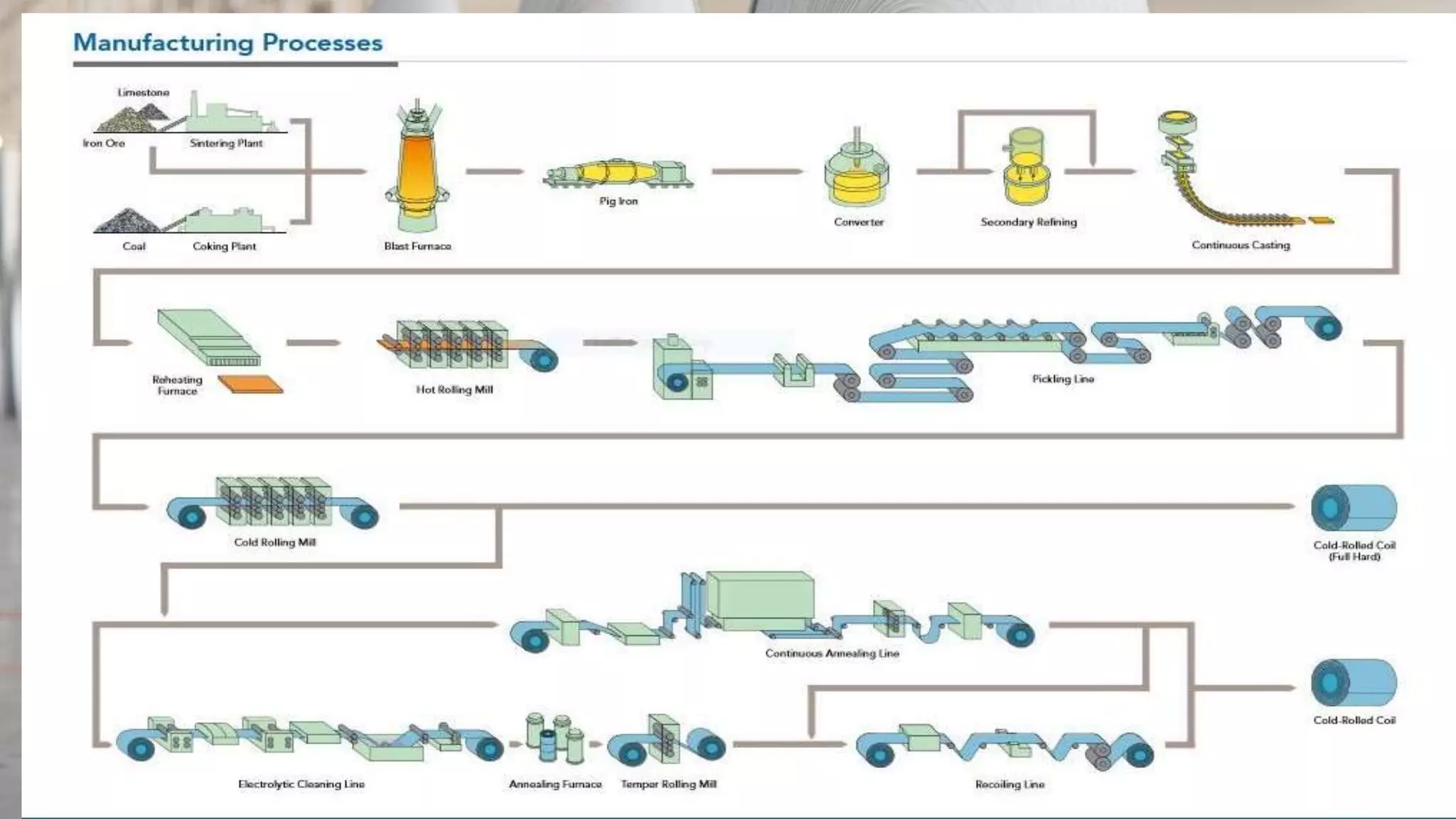

The document discusses cold rolled steel, highlighting its smoother appearance, higher yield and tensile strength compared to hot rolled steel. It outlines various rolling processes, such as roll bending and forge rolling, and their applications in producing components for automotive parts, construction, and appliances. Additionally, it emphasizes the benefits of cold rolling, including enhanced mechanical properties, reduced waste, and improved product quality.

![After the Rolls/Coils are procured, it further undergoes a more detailed process [ SMALL SCALE]

ROLL BENDING

ROLL FORMING

FLAT ROLLING RING ROLLING

STRUCTURAL SHAPE ROLLING

CONTROLLED ROLLING

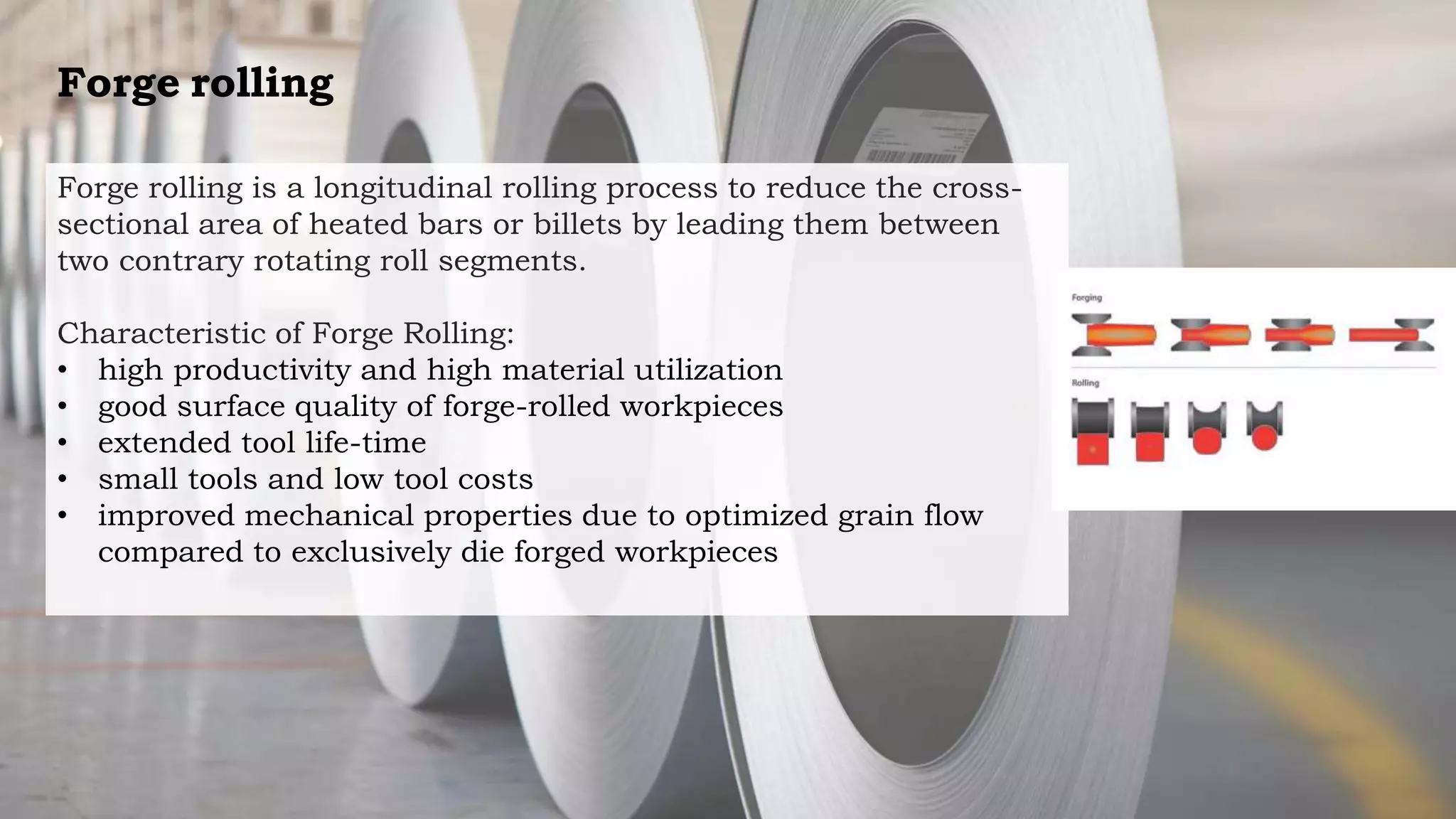

FORGE ROLLING](https://image.slidesharecdn.com/personalcrs-160726124829/75/Cold-Rolled-Sheets-5-2048.jpg)