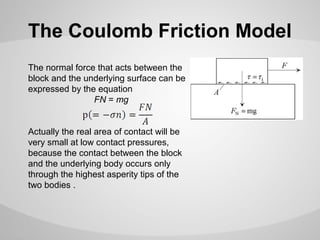

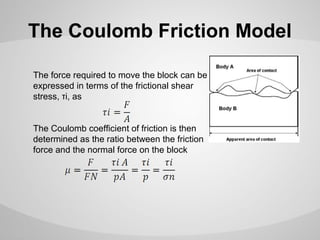

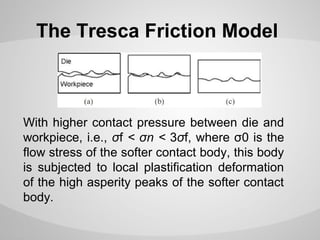

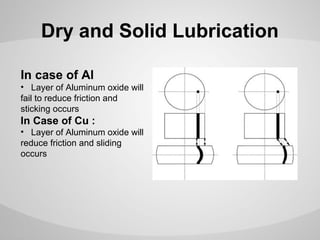

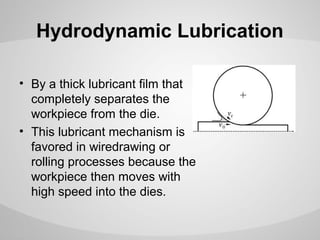

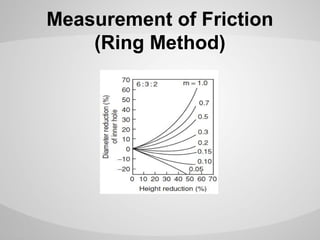

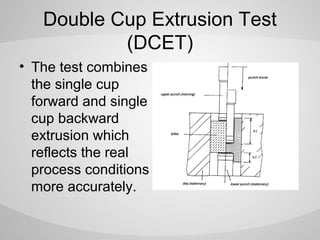

This document discusses friction and lubrication in metal forming processes. It describes two models of friction - the Coulomb friction model which applies at normal stresses below the workpiece's flow stress, and the Tresca friction model at higher normal stresses. The key lubrication mechanisms are also outlined, including dry lubrication, hydrodynamic lubrication using high-speed fluid films, and boundary film lubrication preferred for sheet metal forming. Methods for measuring friction coefficients like the ring test and double cup extrusion test are also presented.