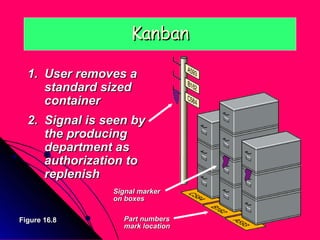

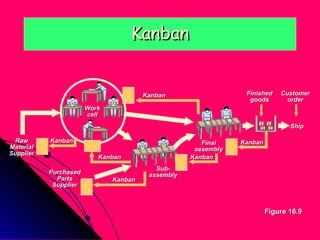

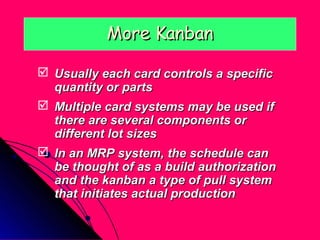

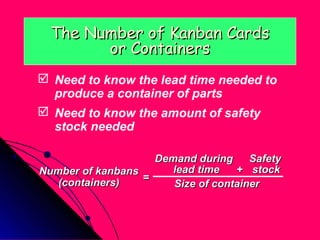

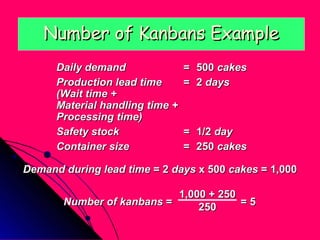

JIT (Just In Time) manufacturing is a philosophy based on eliminating waste and continuously improving productivity. It uses a 'pull' system where actual customer orders trigger production of only what is needed, when it's needed, in the required quantity. Key benefits include lower stock levels and working capital requirements, less waste from obsolete or expired stock, and improved quality from an emphasis on getting production right the first time. However, JIT relies on reliable suppliers and lacks buffer stock for unexpected demand. Kanban is a visual signal system used in JIT to authorize production of new containers/lots and pull materials through the process.