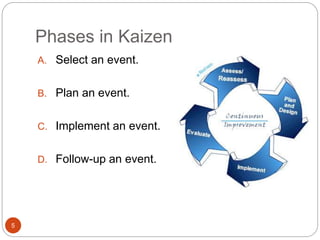

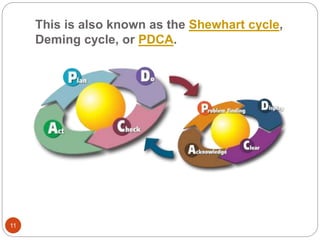

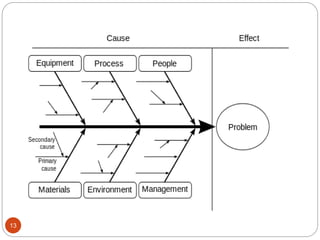

Kaizen is a Japanese philosophy that focuses on continuous improvement of processes in small incremental steps. It was developed by Masaaki Imai and means "change for better" with "Kai" meaning change and "Zen" meaning good. The main principles of Kaizen involve considering the entire process, evaluating how to best complete a job, and making improvements without blame. Kaizen aims to be widely applicable, effective, a learning experience, and team-based. It uses techniques like PDCA cycles and 5 whys to standardize, measure, innovate, and continuously improve processes over time. The goals of Kaizen are to reduce waste, improve quality and space utilization, and increase employee satisfaction and problem solving.