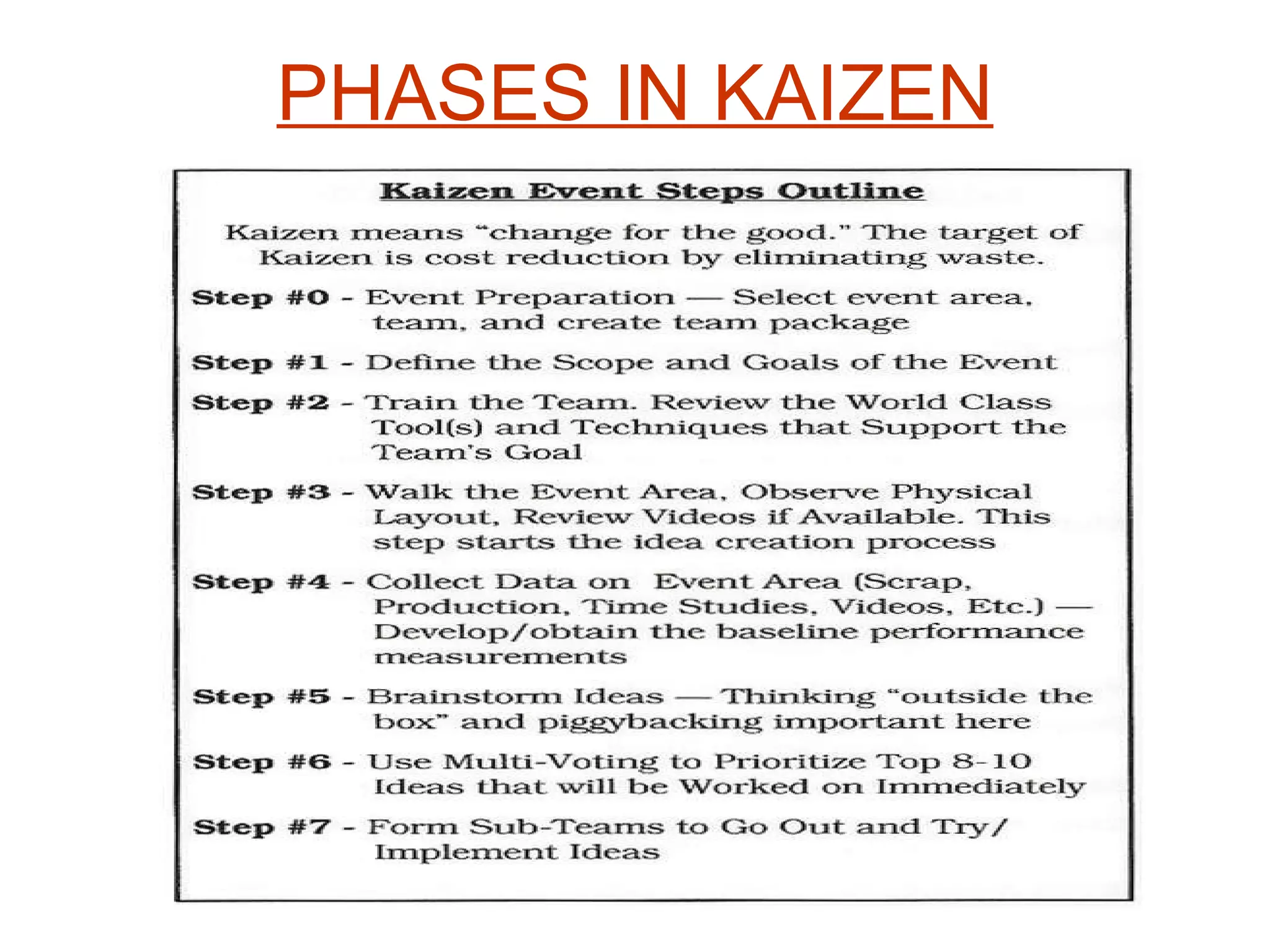

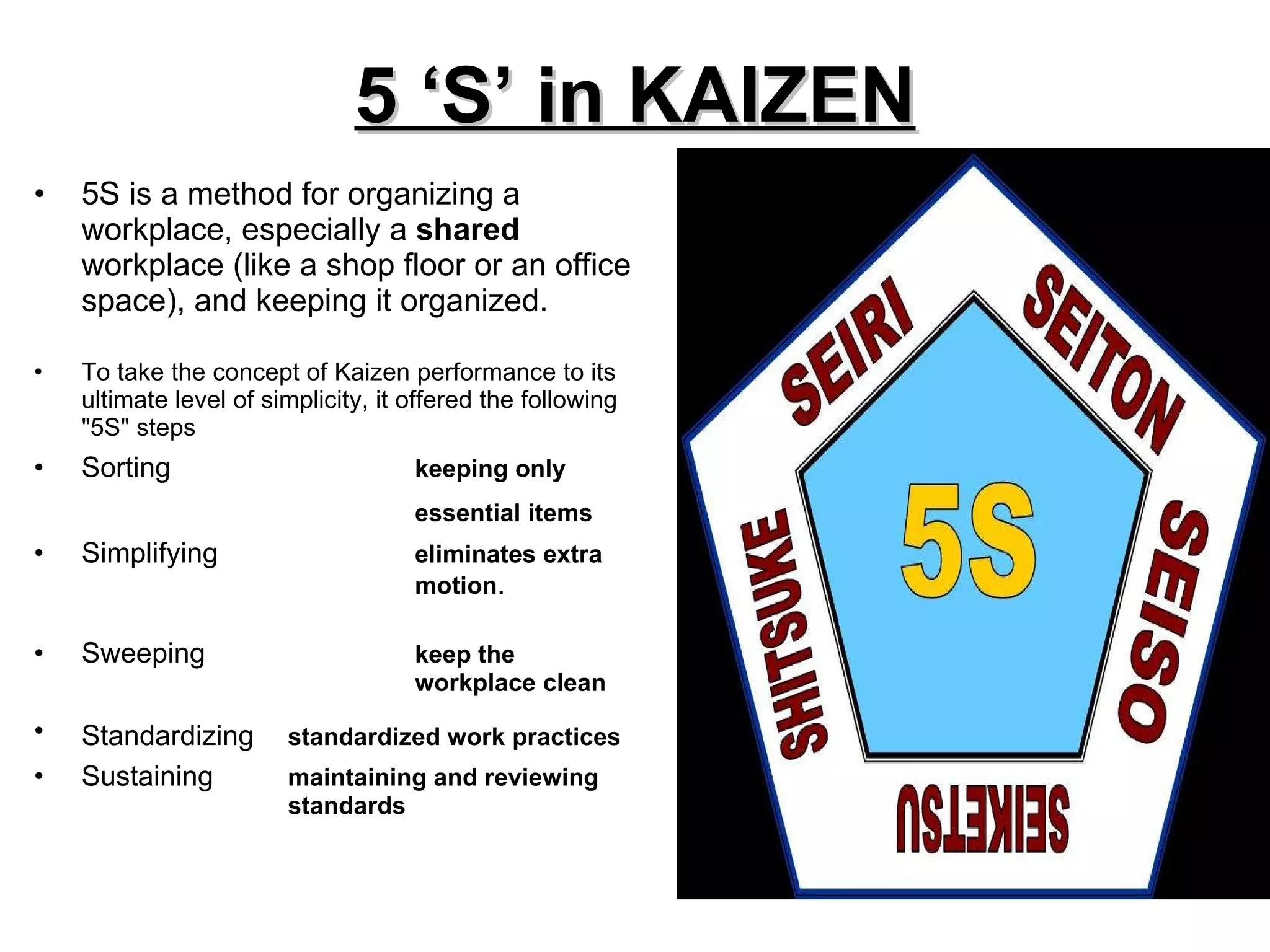

The document discusses the concept of Kaizen, which refers to continuous improvement through small, incremental changes. It describes the key features and benefits of Kaizen, including that it is widely applicable, results-oriented, a learning experience, team-based, and reduces waste. The document also outlines the typical phases of a Kaizen event and different Kaizen methods, and discusses the "5S" approach and potential pitfalls to Kaizen implementation.