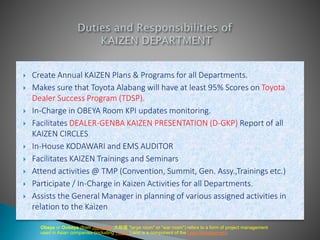

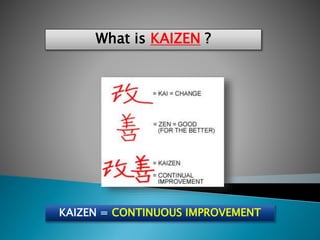

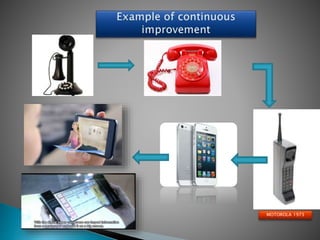

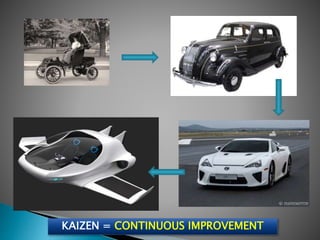

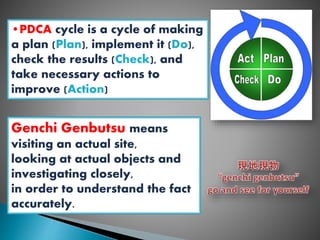

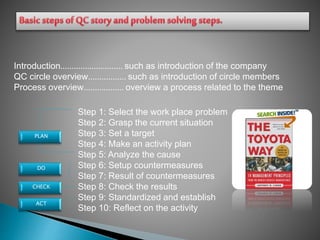

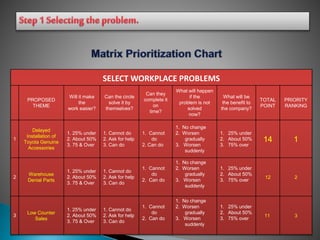

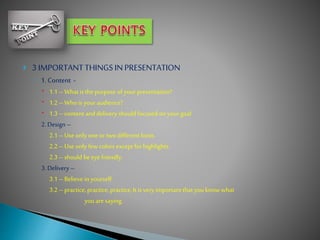

The document provides an overview of a company orientation on Kaizen and quality control circles. It discusses the meaning of Kaizen as continuous improvement and outlines the Toyota Production System. It then explains the basic principles and significance of quality control circle activities, including selecting problems, grasping current situations, setting targets, and using the PDCA cycle. The document concludes by outlining best practices for presentations, including focusing on clear content for the intended audience and effective design and delivery techniques.