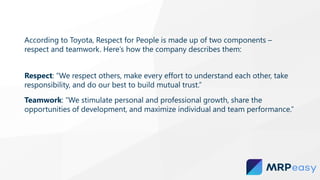

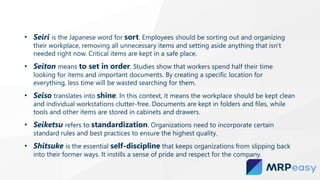

Kaizen, meaning 'continuous improvement,' is a philosophy popularized by Masaaki Imai that emphasizes incremental changes and employee involvement in problem-solving within organizations. It operates on core principles that challenge assumptions, encourage initiative, and foster a culture of collaboration and respect, with the process structured in a cyclical method for ongoing assessment and improvement. Additionally, the 5S program, associated with Kaizen, focuses on workplace organization and cleanliness, driving higher efficiency, safety, and profitability.