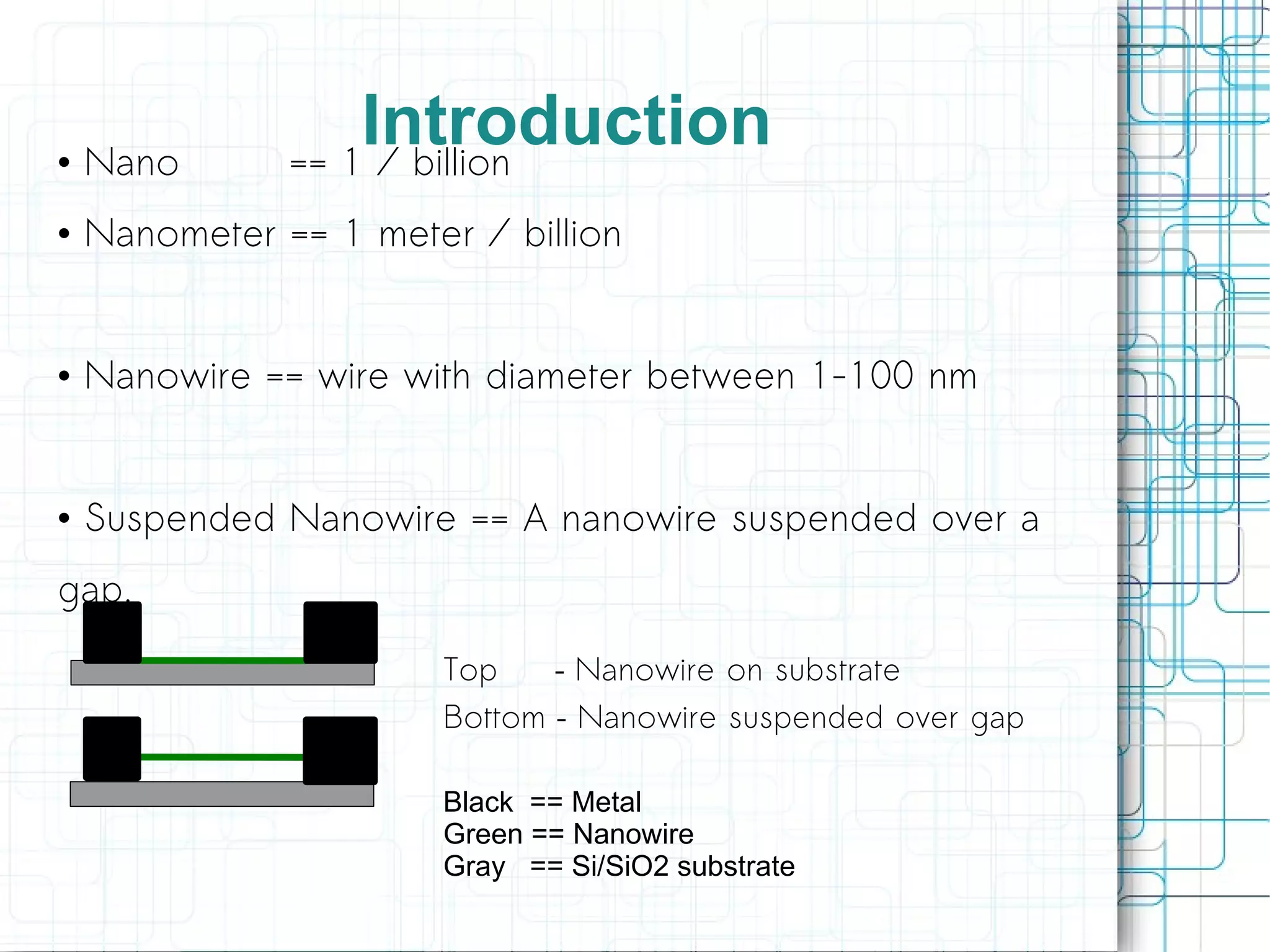

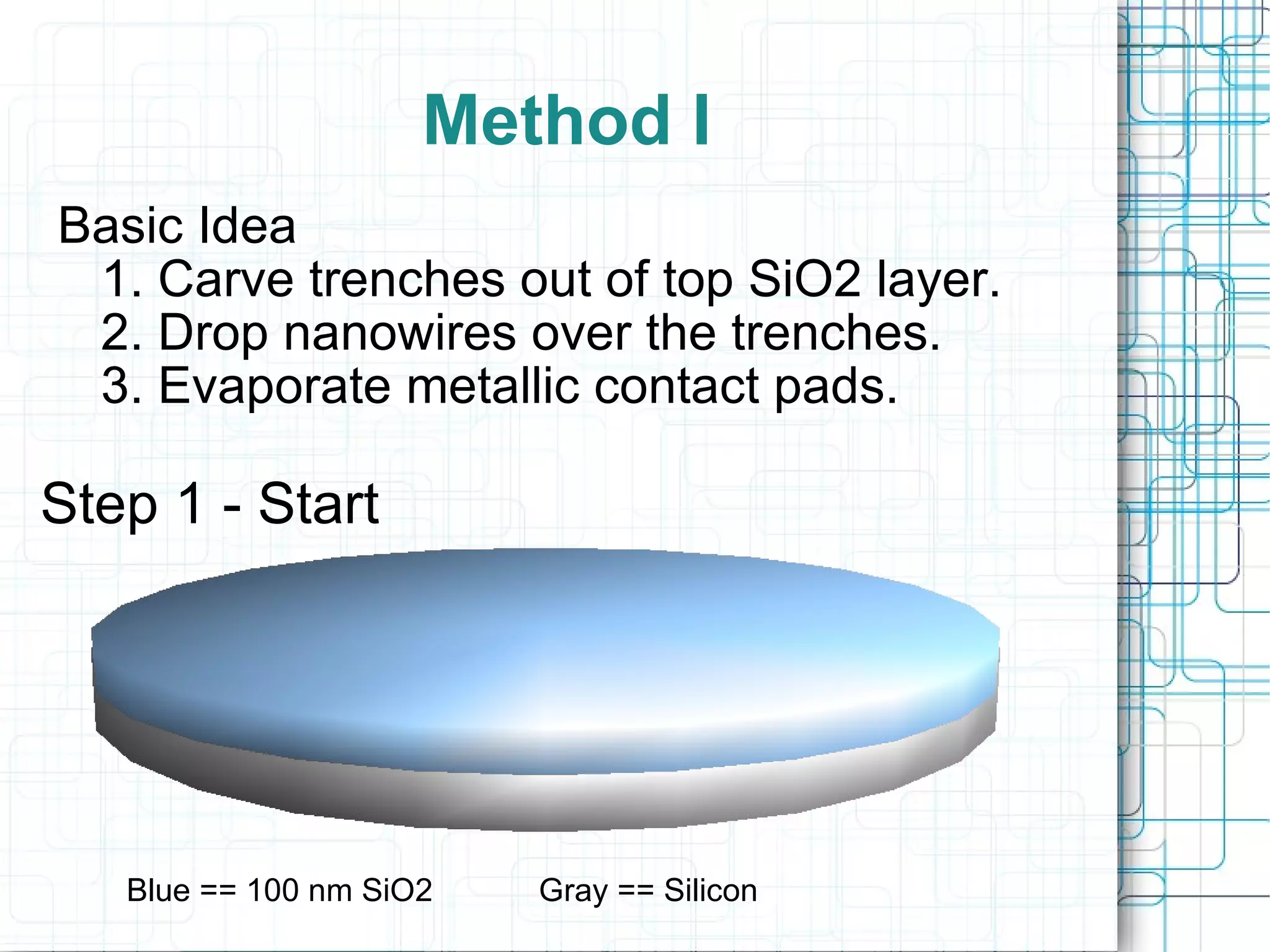

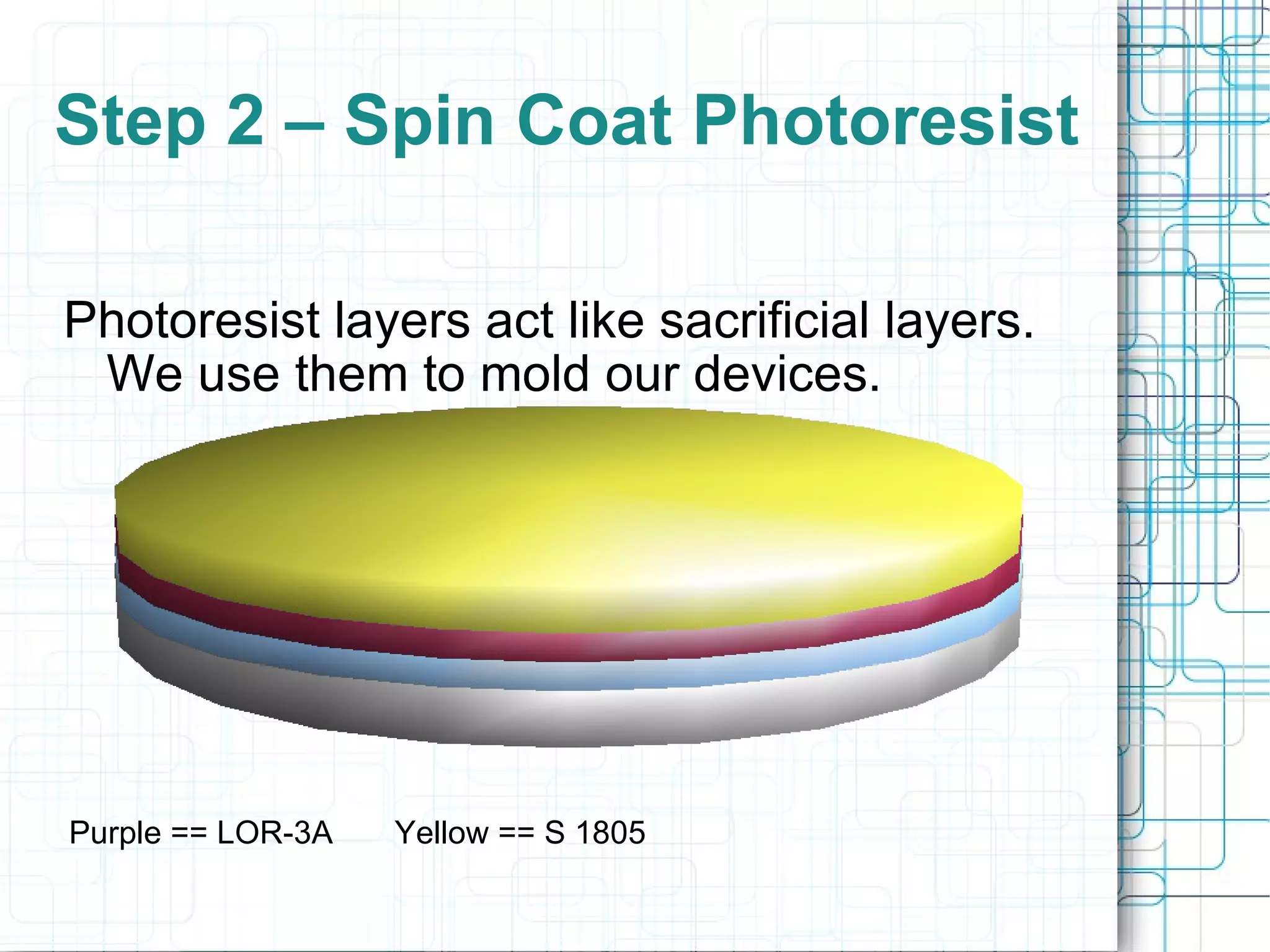

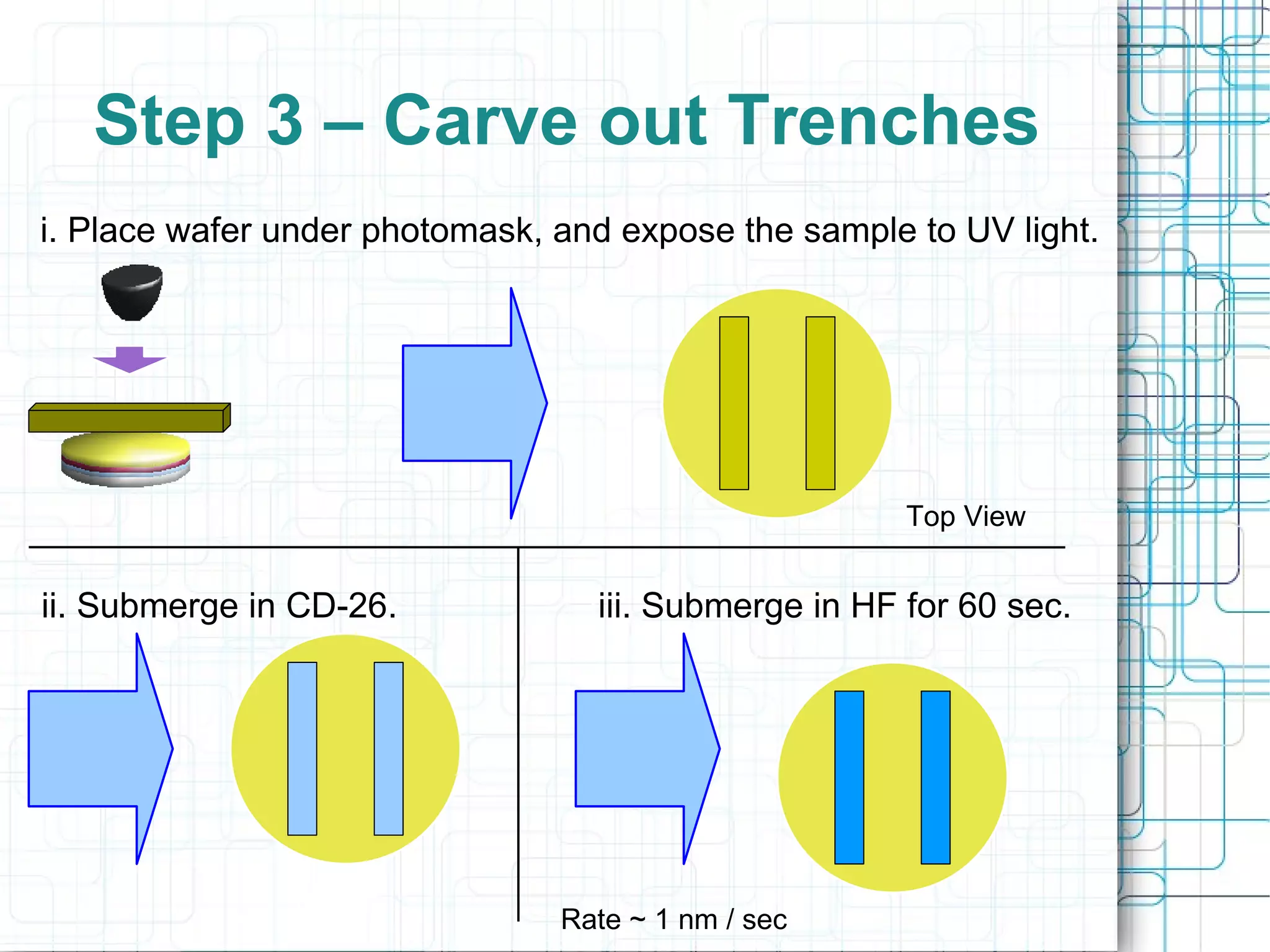

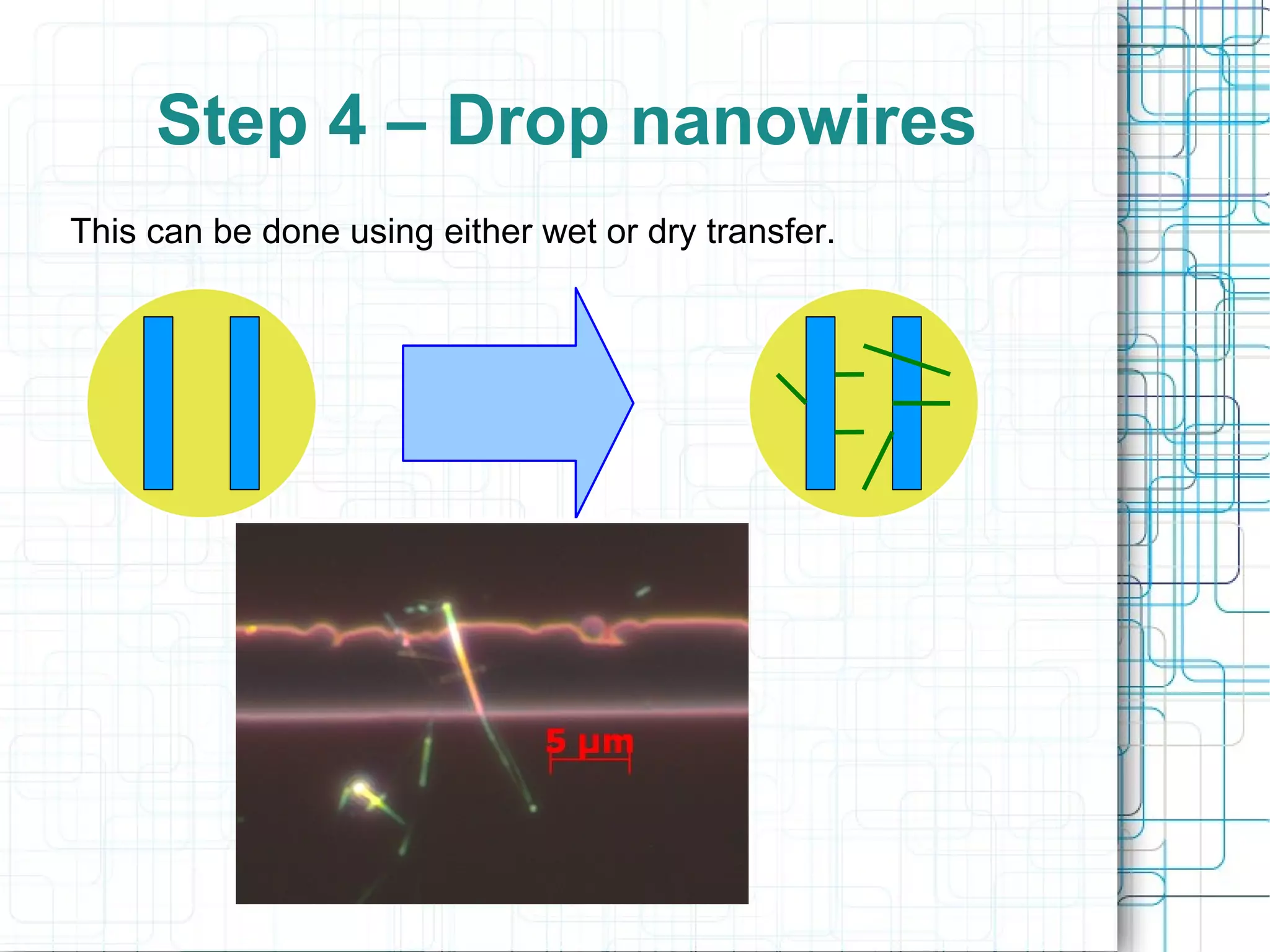

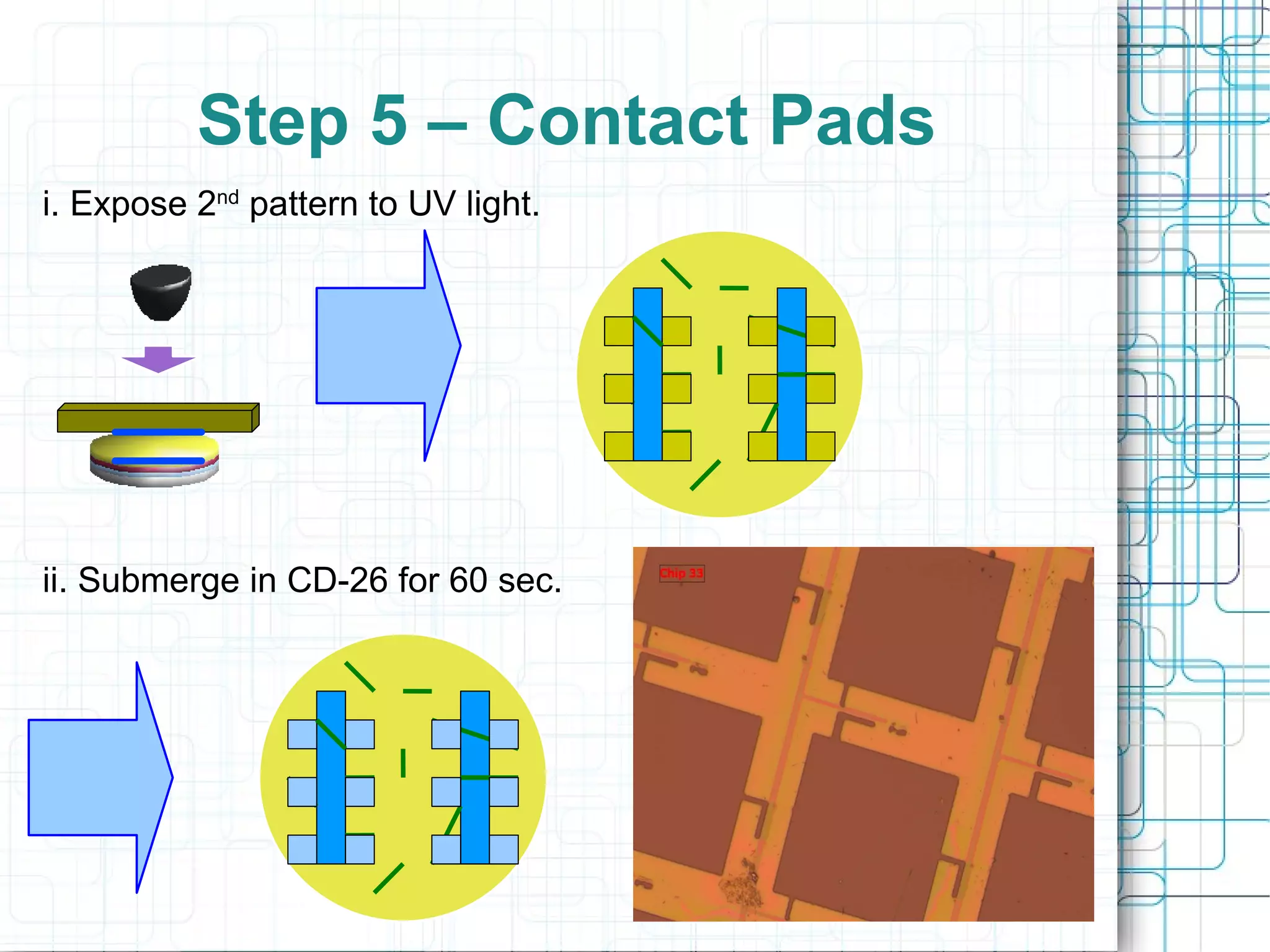

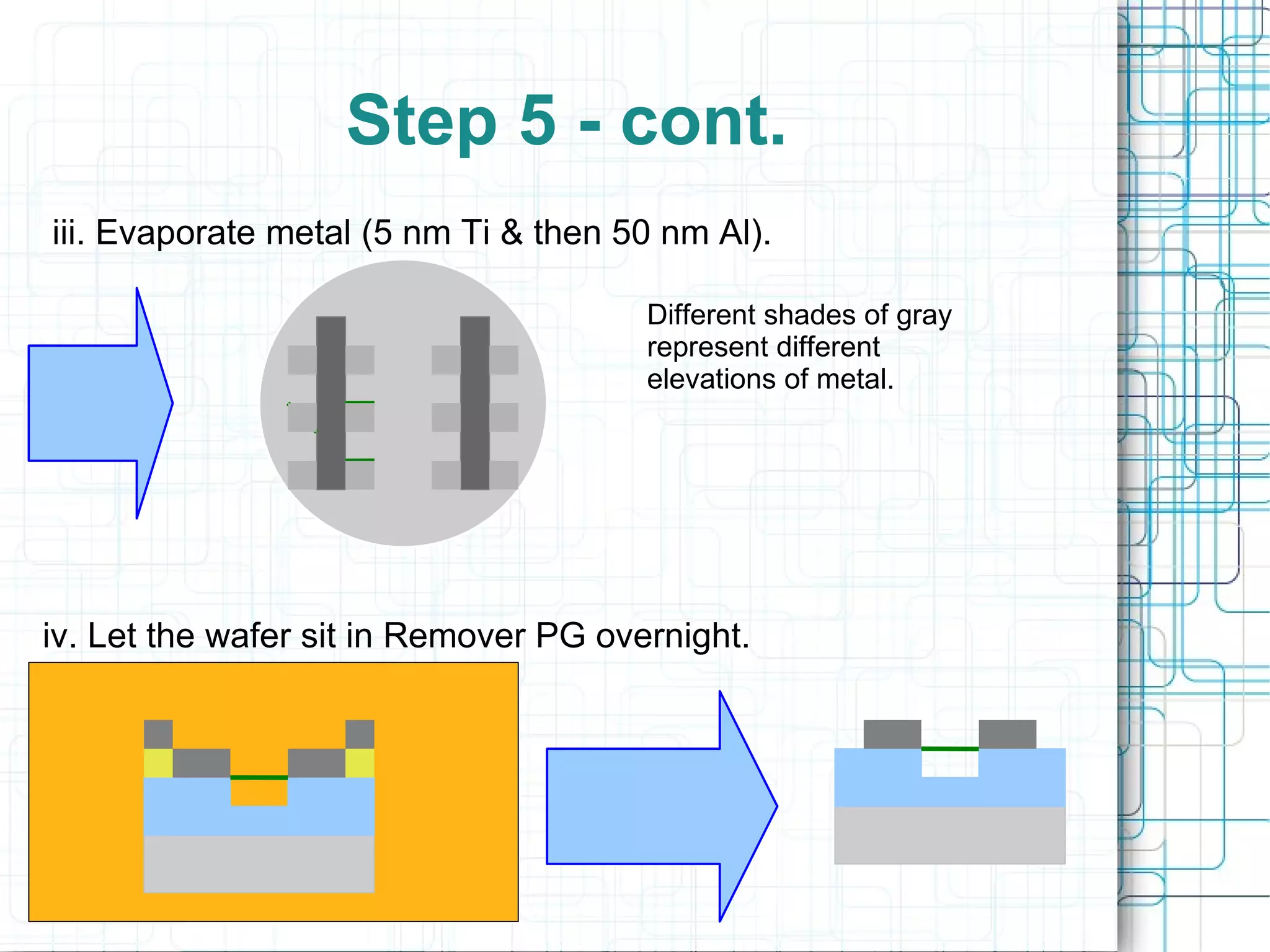

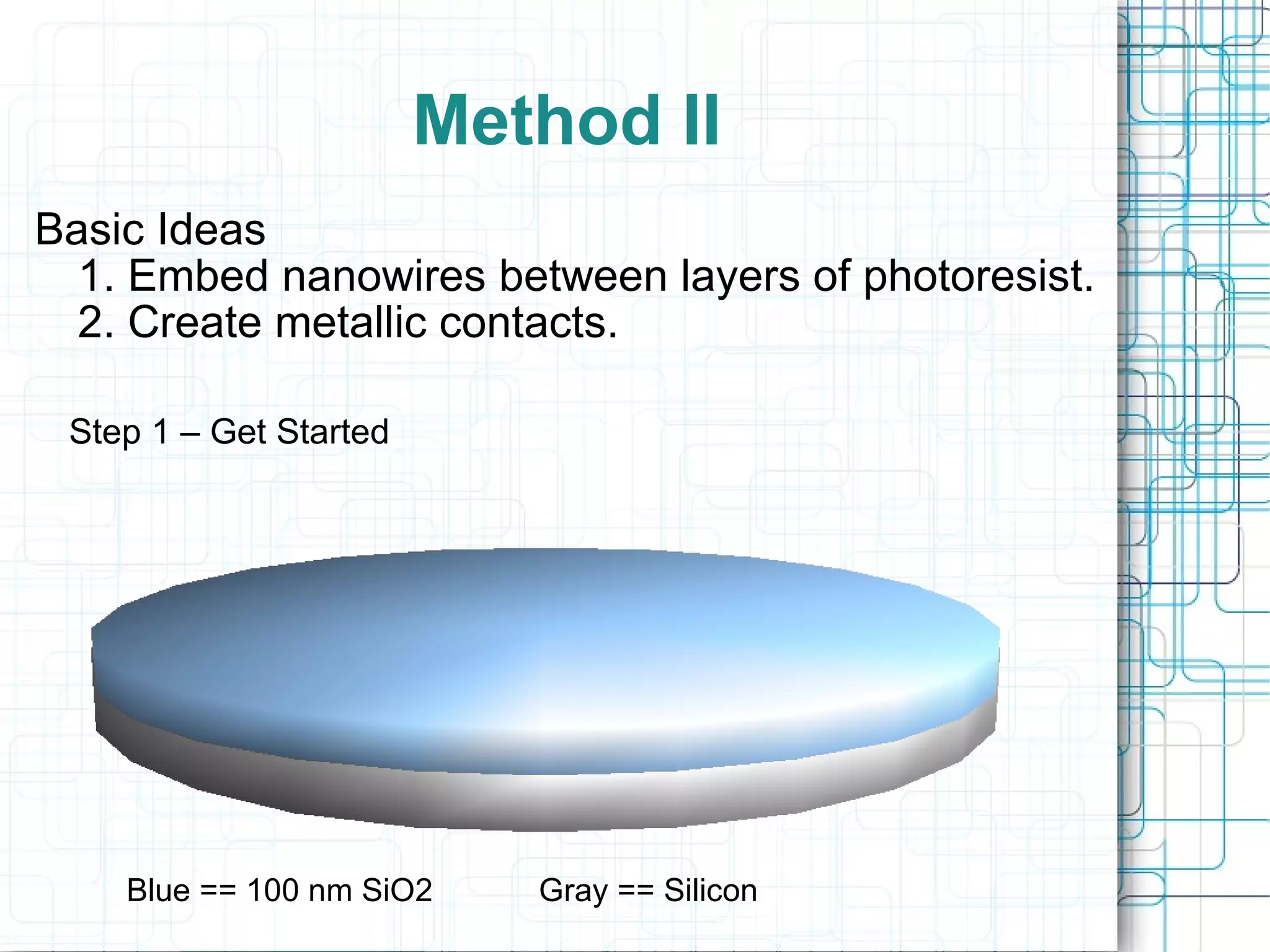

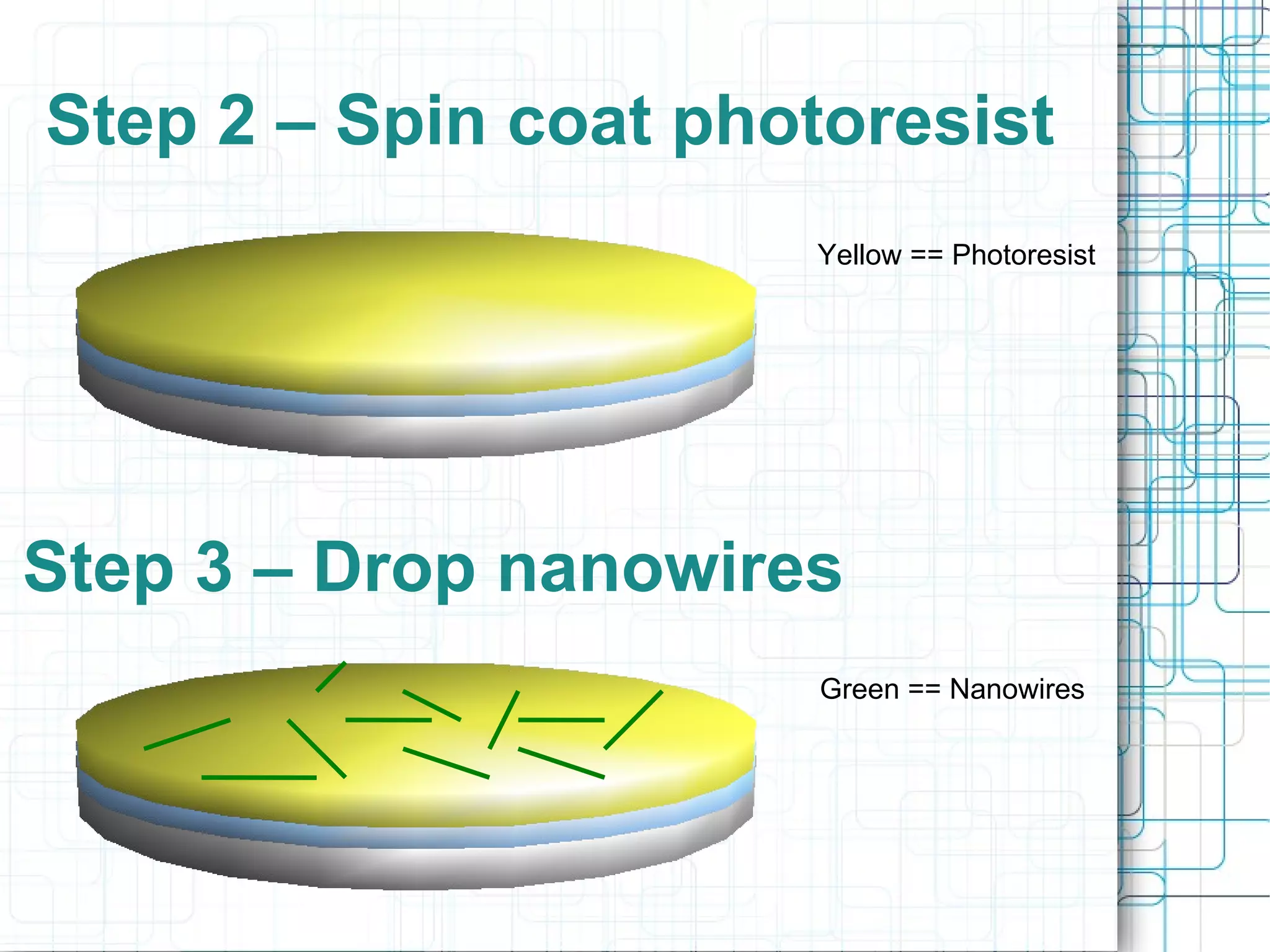

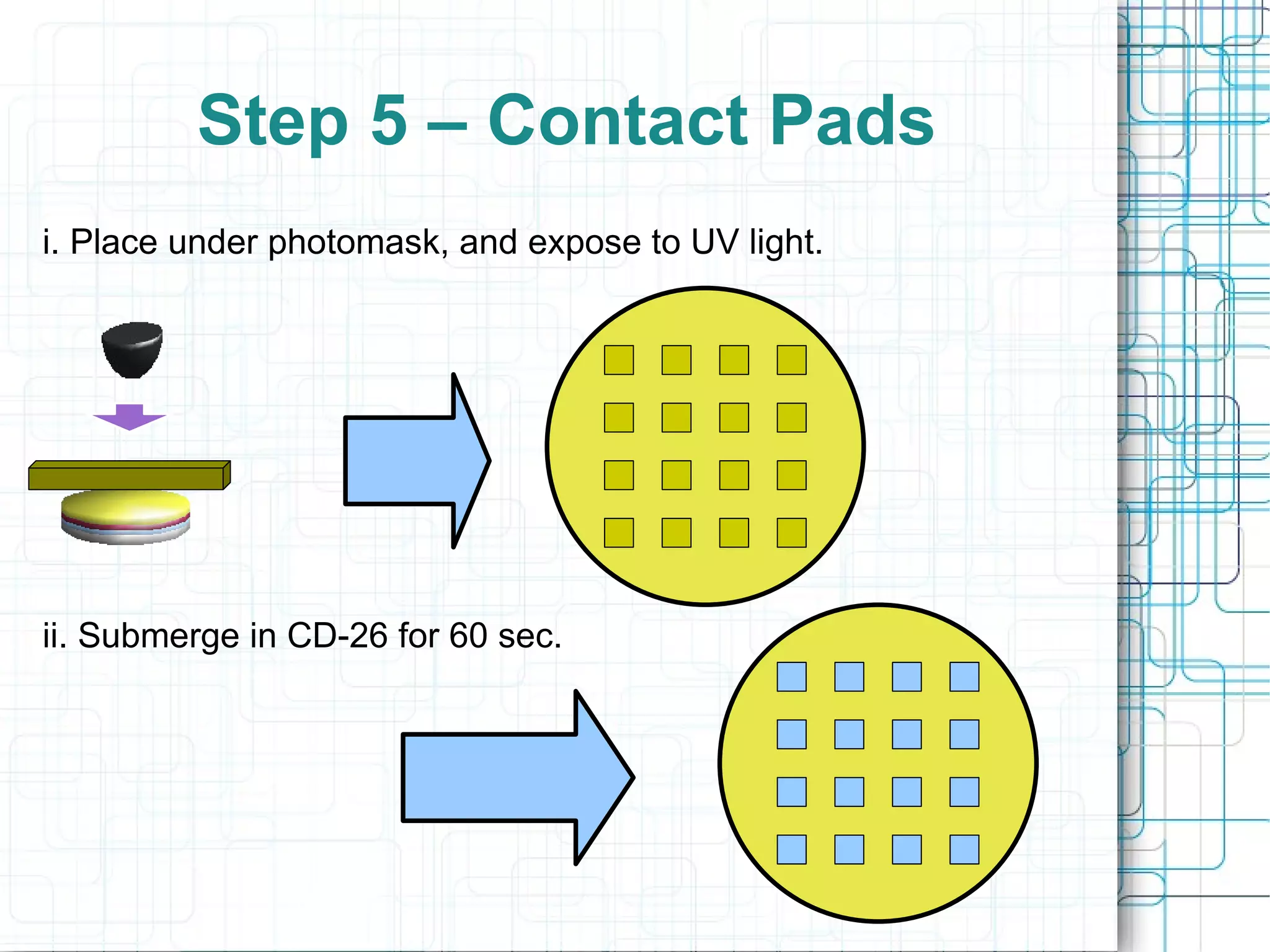

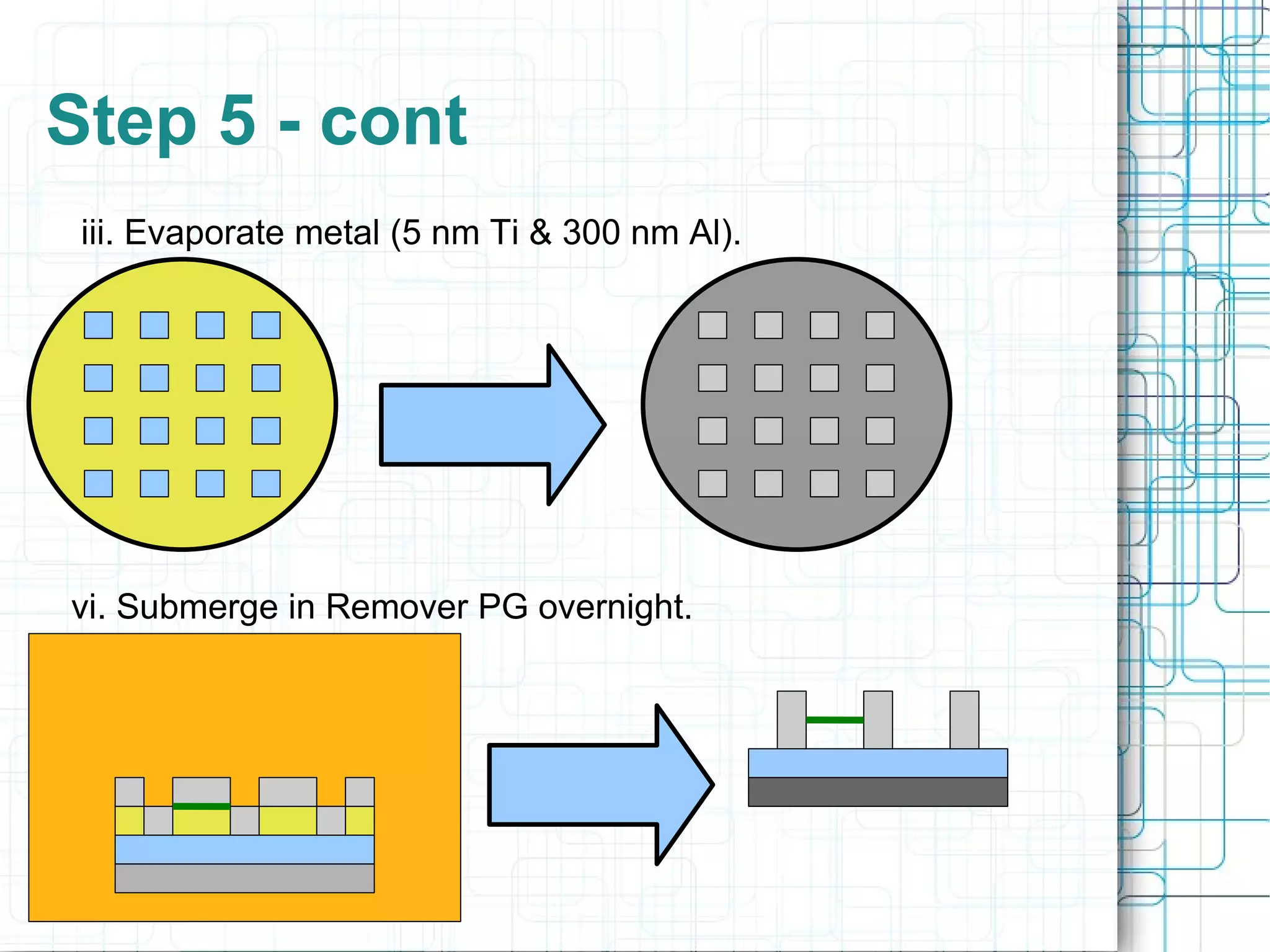

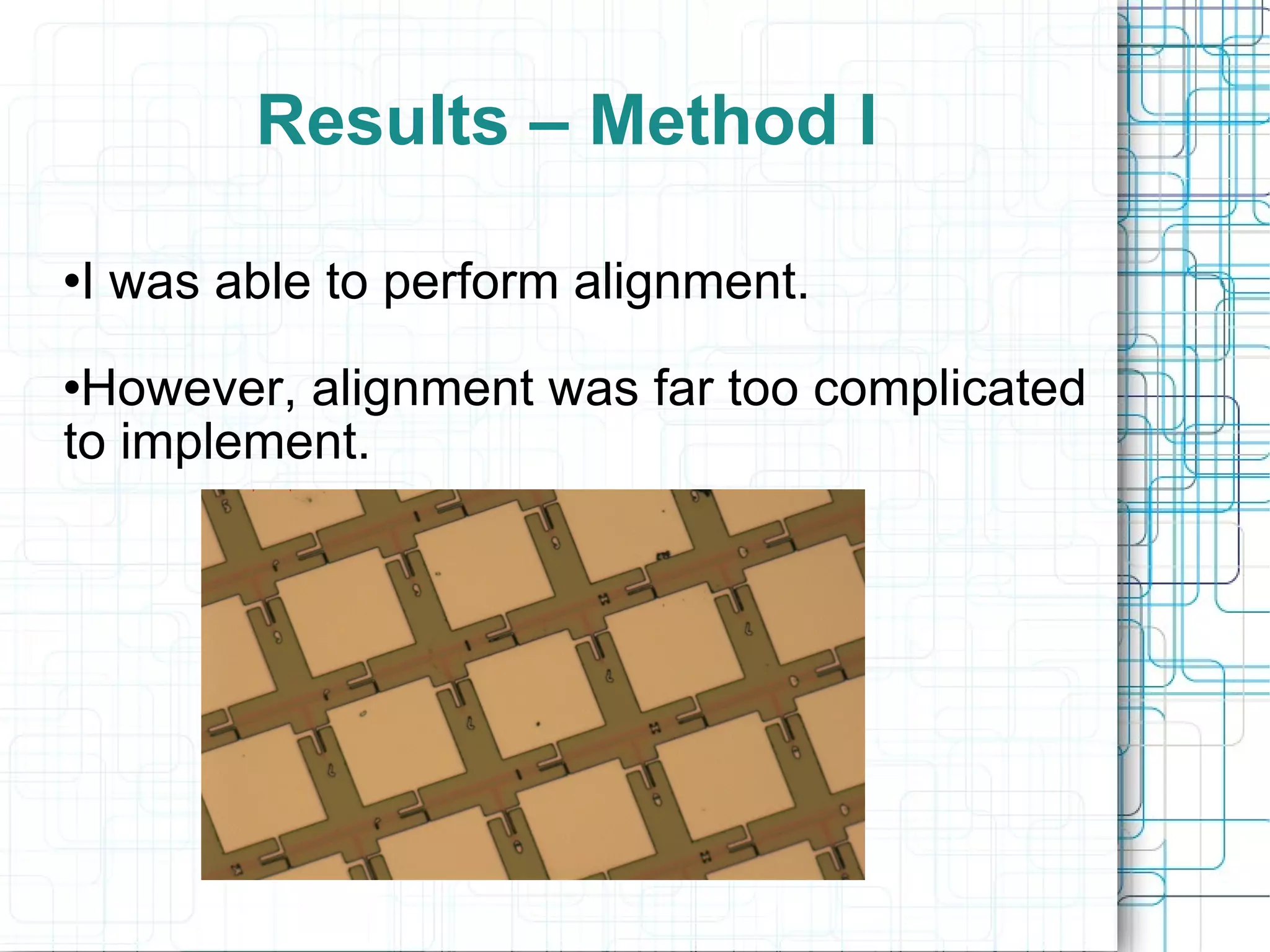

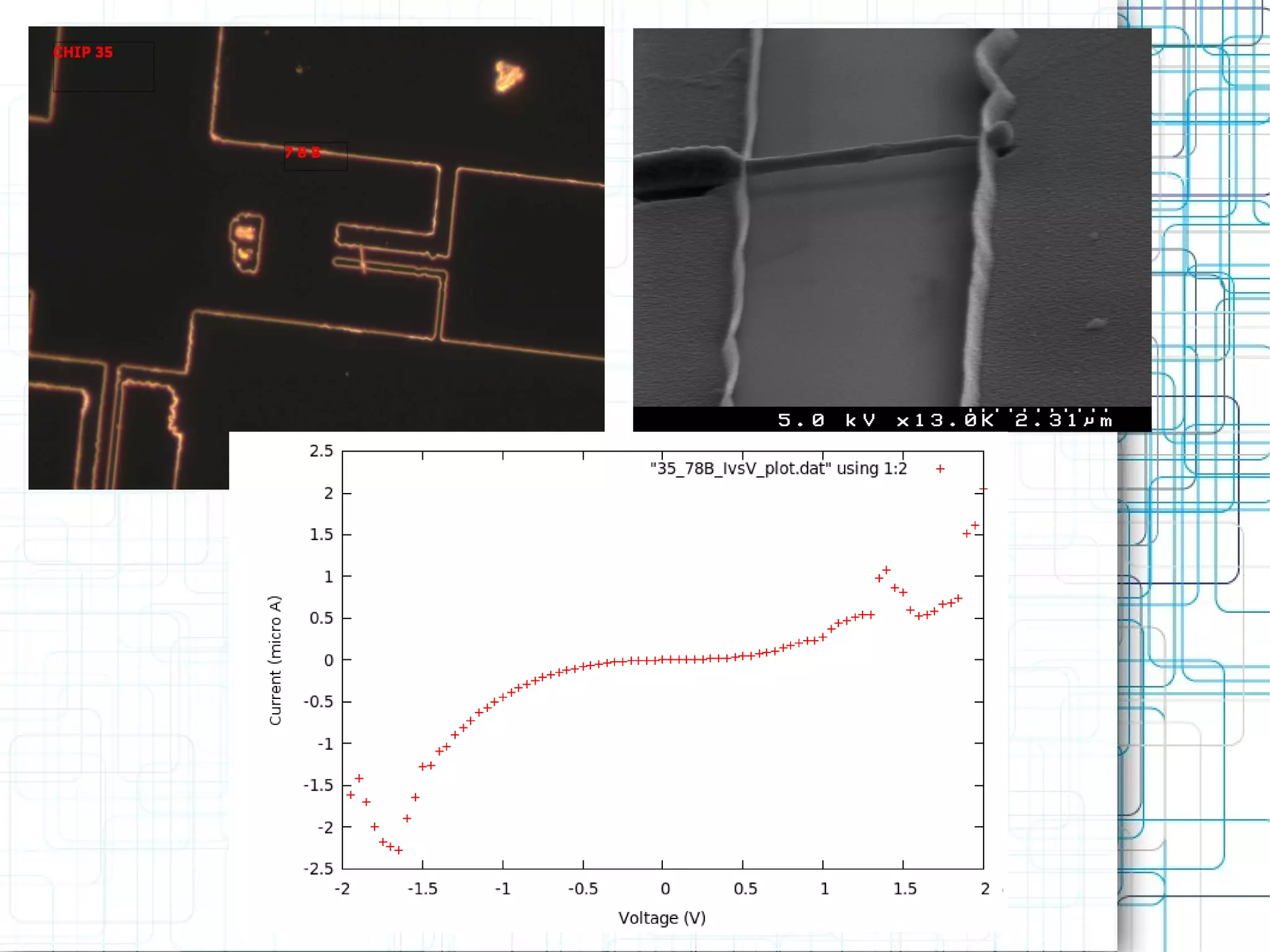

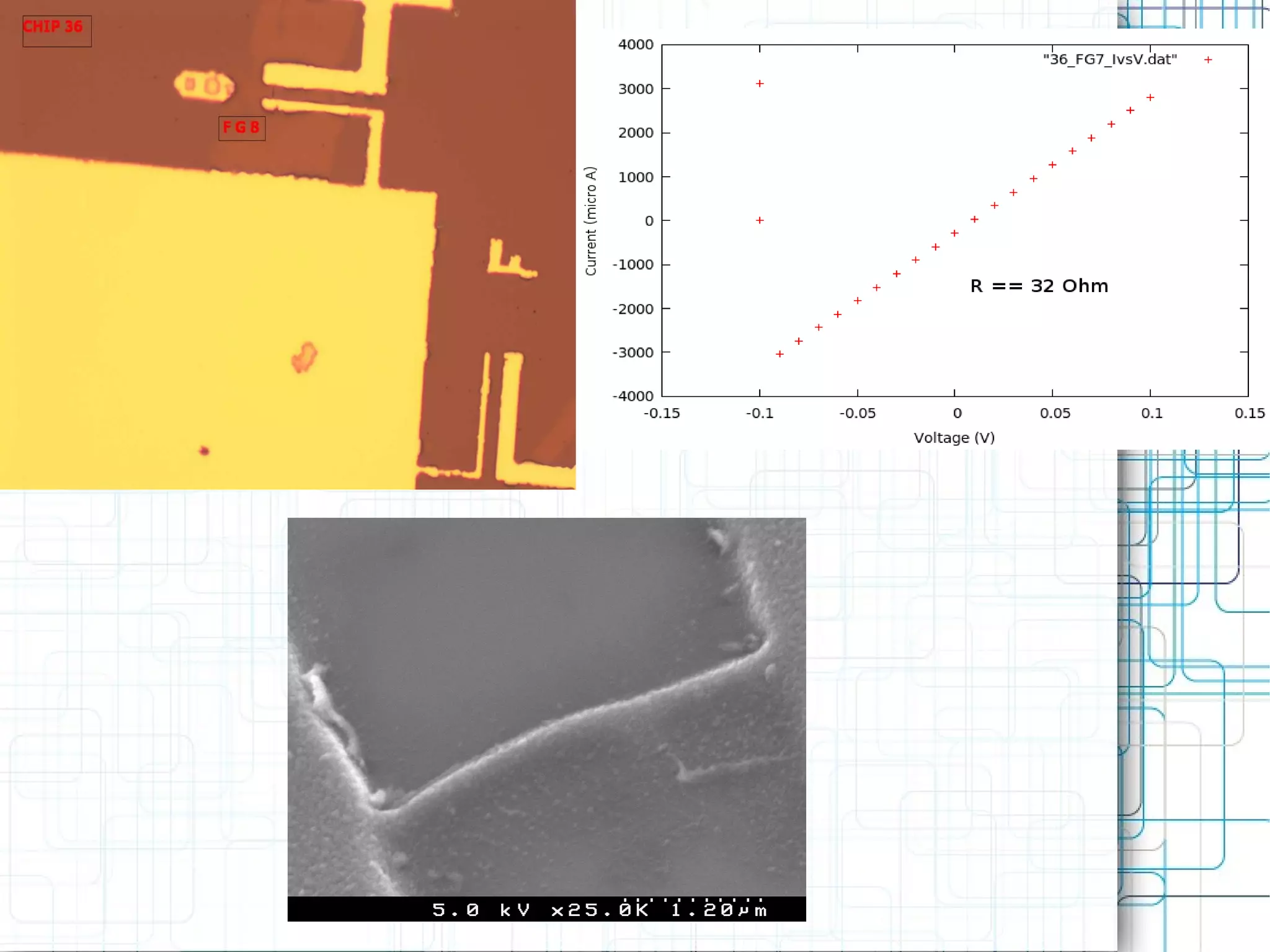

This document summarizes two methods for fabricating suspended nanowire structures. Method 1 involves carving trenches in silicon dioxide and dropping nanowires over the trenches. Method 2 embeds nanowires between layers of photoresist and creates metallic contacts. The goals are to fabricate suspended nanowire devices and test their I-V curves. While alignment was too complicated in Method 1, Method 2 successfully produced suspended nanowire structures and preliminary I-V curve measurements.