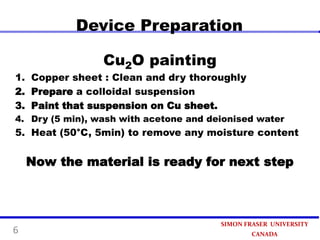

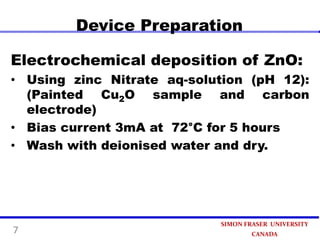

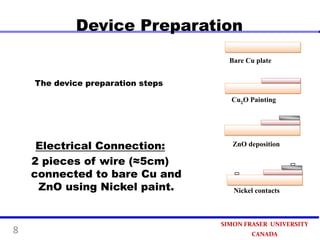

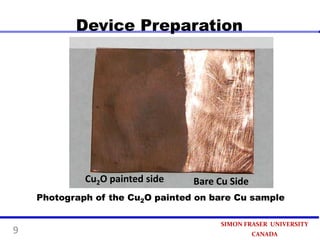

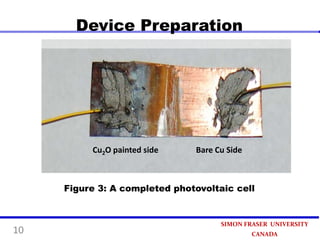

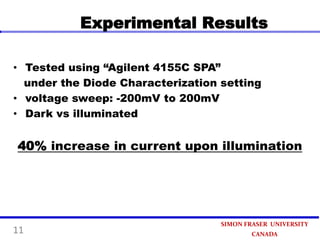

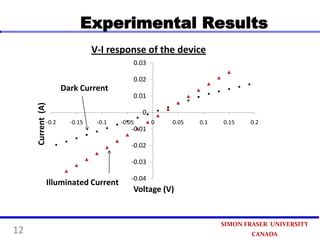

This document summarizes research on developing a low-cost photovoltaic device using copper oxide (Cu2O) and zinc oxide (ZnO). The device is prepared through three steps: 1) painting a copper sheet with a Cu2O colloidal suspension, 2) depositing ZnO using electrochemical deposition, and 3) connecting electrodes. Experimental results found a 40% increase in current when the device was illuminated, demonstrating its photovoltaic effect. The simple preparation process paves the way for an ultra-economical approach to produce photovoltaic devices in the future.

![Background

•

•

•

•

1920s: Cu2O rectifier

1930s: Cu2O photosensitive device

1970s: Research on Cu2O photovoltaic cells

Reported efficiency 2%. At present: 20% [1,2]

• 1980s: Three main issues of Cu2O solar cells:

1. A sound method of preparation of Cu2O

2. Increasing the photoconductivity of Cu2O

3. Making a good P-N junction [3]

3

SIMON FRASER UNIVERSITY

CANADA](https://image.slidesharecdn.com/347cu2osolarcell9-131211043036-phpapp01/85/347-cu2-o-solar-cell-9-3-320.jpg)

![Introduction

• Solar cells research - popular topic now

worldwide need for clean and renewable energy.

• Cu2O Benefits (p-type):

Availability & low cost to develop

Efficiency 20%

Band gap 2 eV[4]

• ZnO (n-type): easy to manufacture and low cost.[4]

The combination of Cu2O and ZnO

inexpensive photoconductive device.

4

SIMON FRASER UNIVERSITY

CANADA](https://image.slidesharecdn.com/347cu2osolarcell9-131211043036-phpapp01/85/347-cu2-o-solar-cell-9-4-320.jpg)