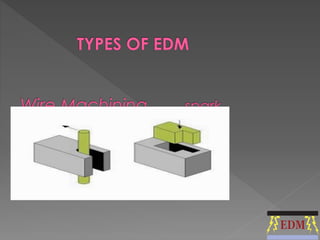

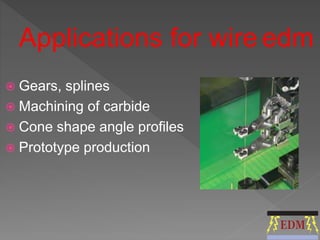

The document discusses electro discharge machining (EDM), a machining method used for hard, electrically conductive metals. EDM works by using electrical sparks to erode unwanted material away from a workpiece. This allows machining of metals that other techniques cannot cut. The document covers the history of EDM's development, how the process works using sparks and a dielectric fluid, and different EDM techniques like wire EDM and spark EDM as well as their applications and advantages/disadvantages.