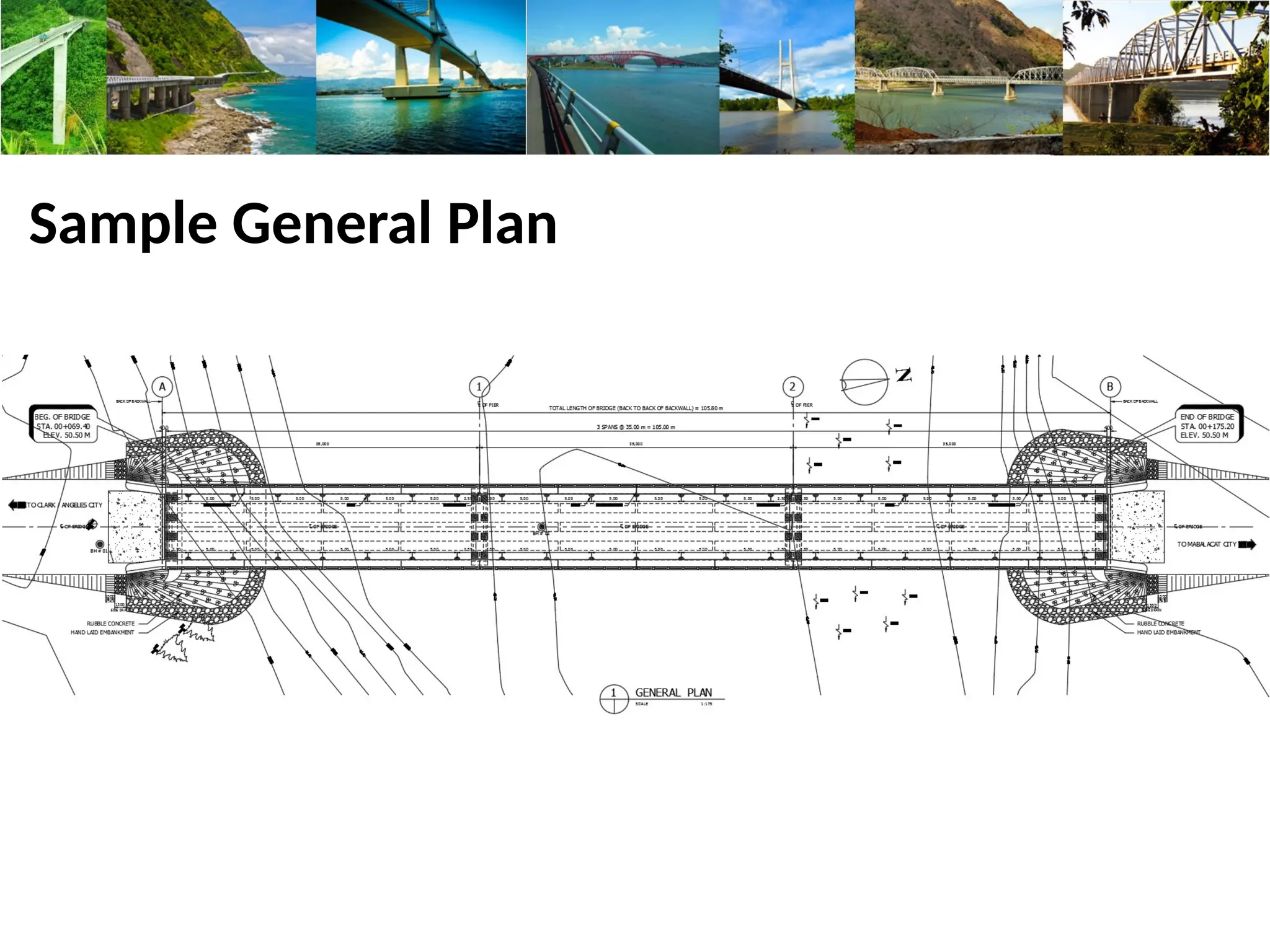

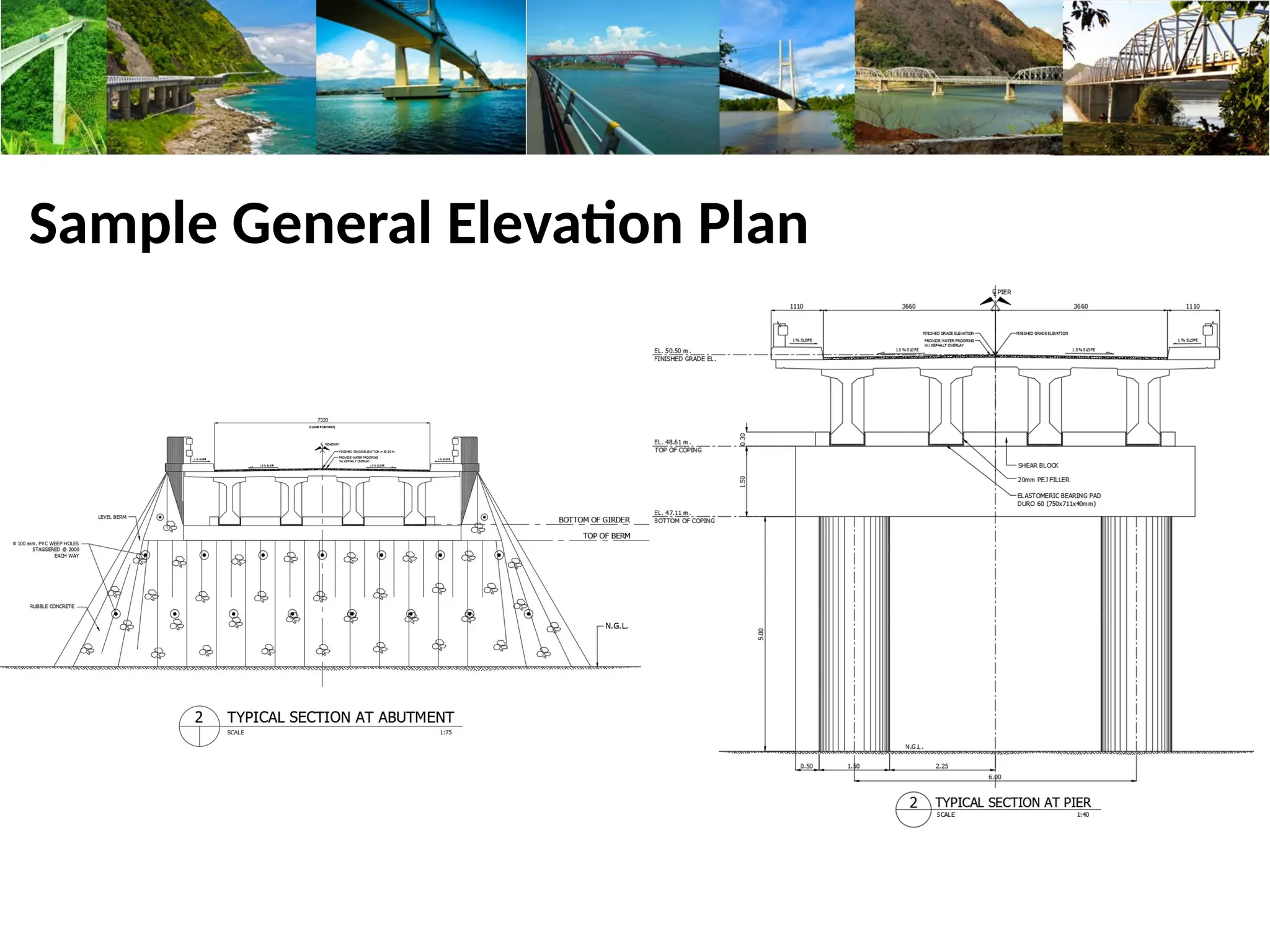

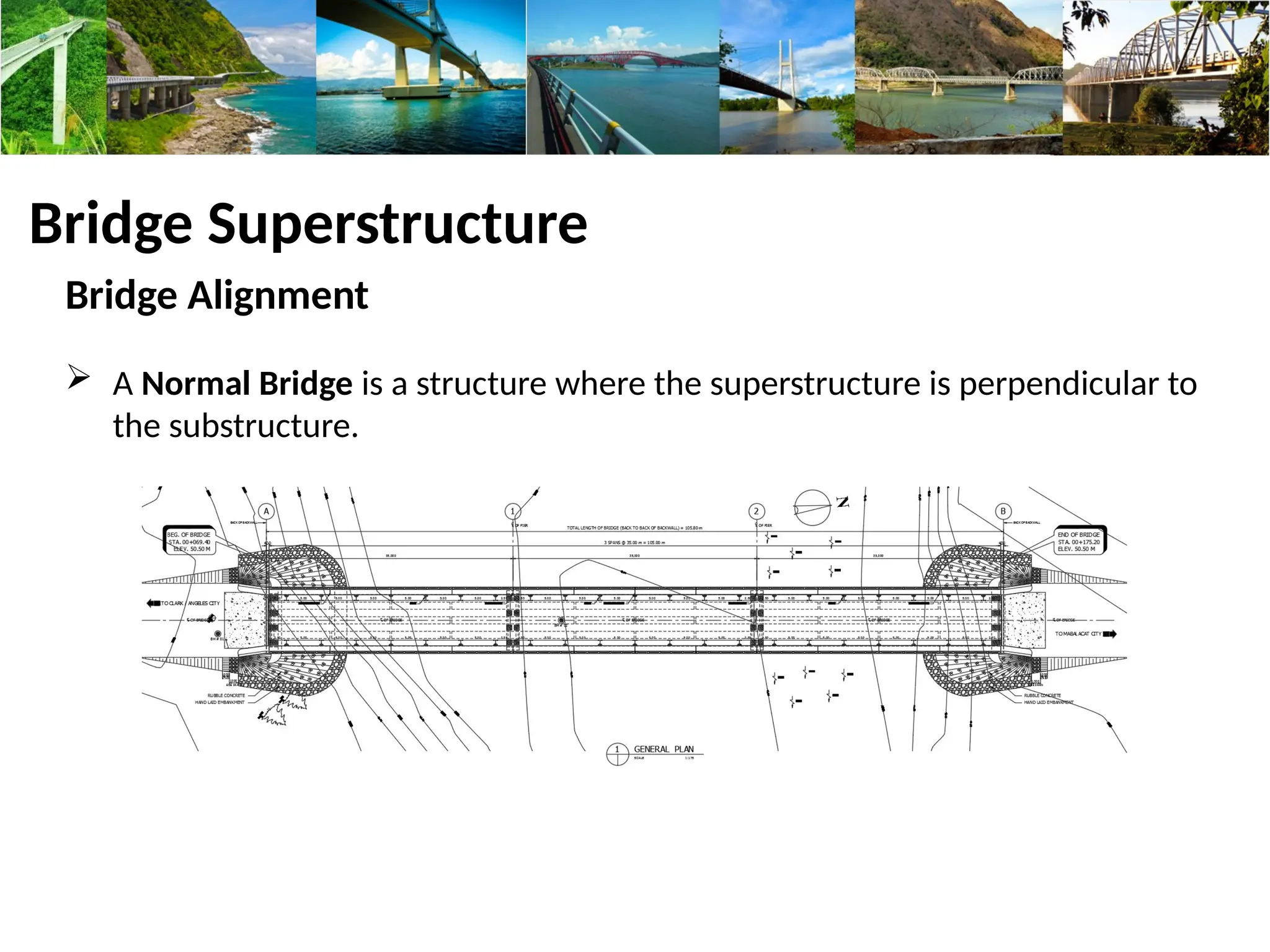

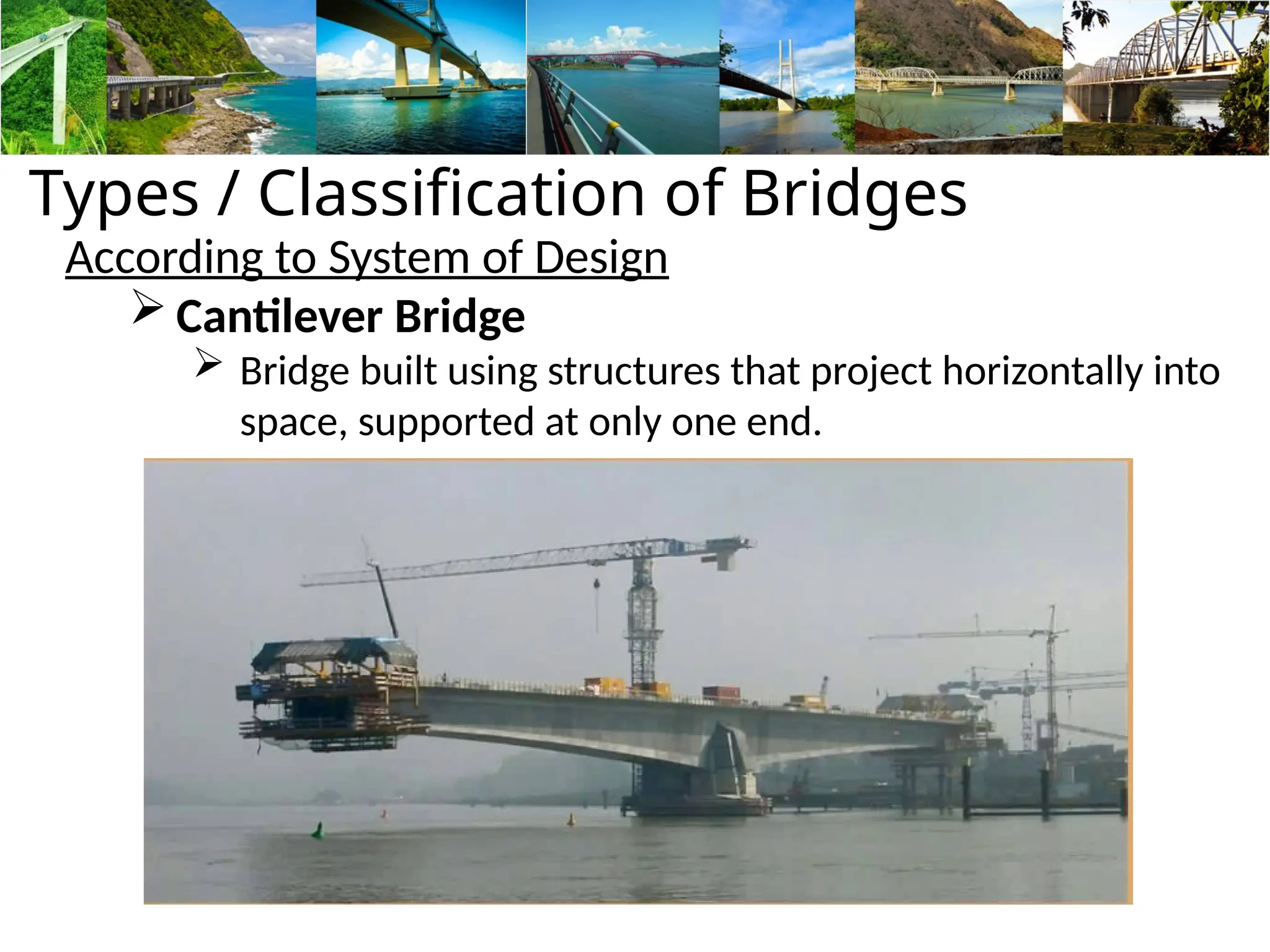

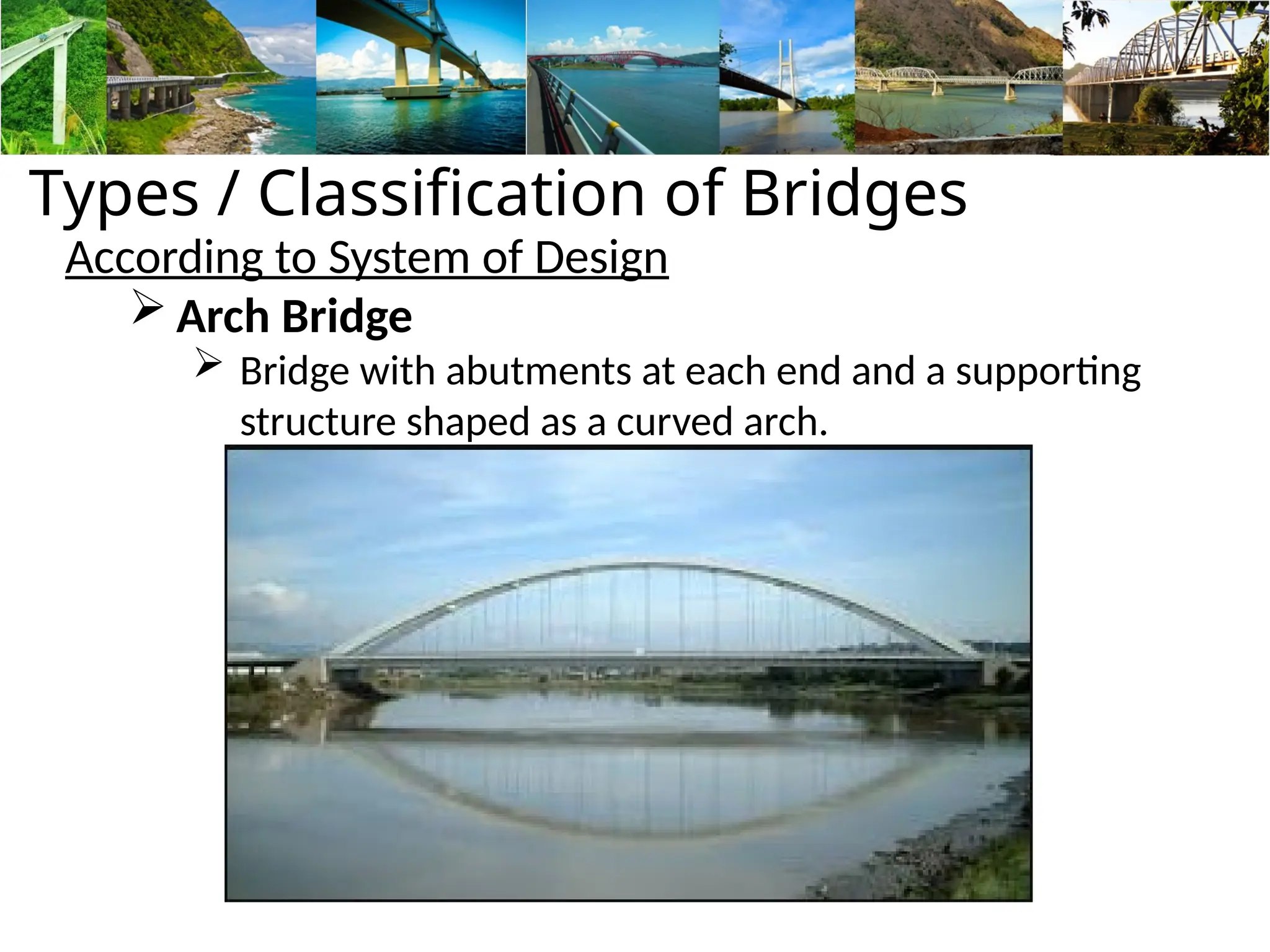

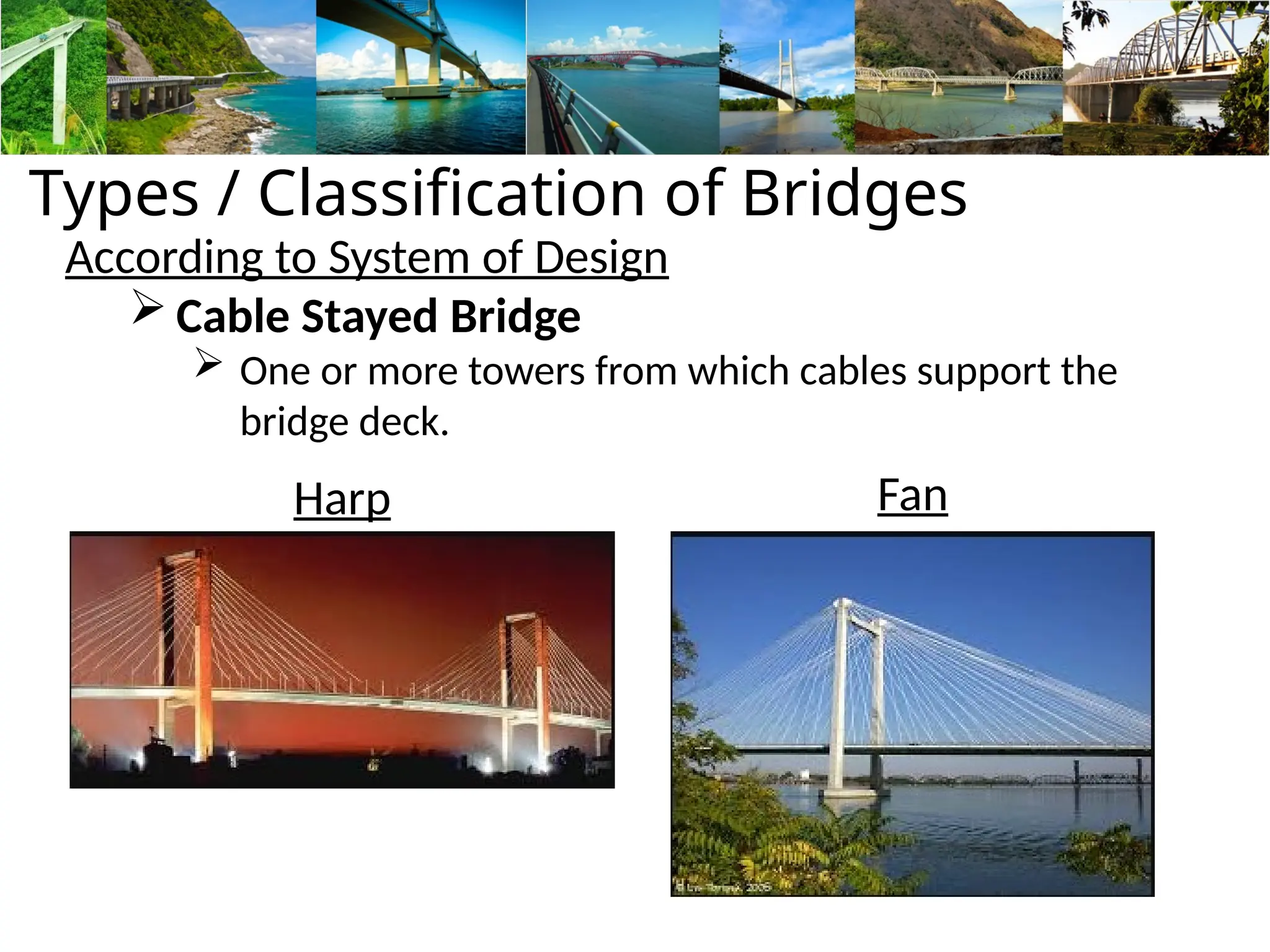

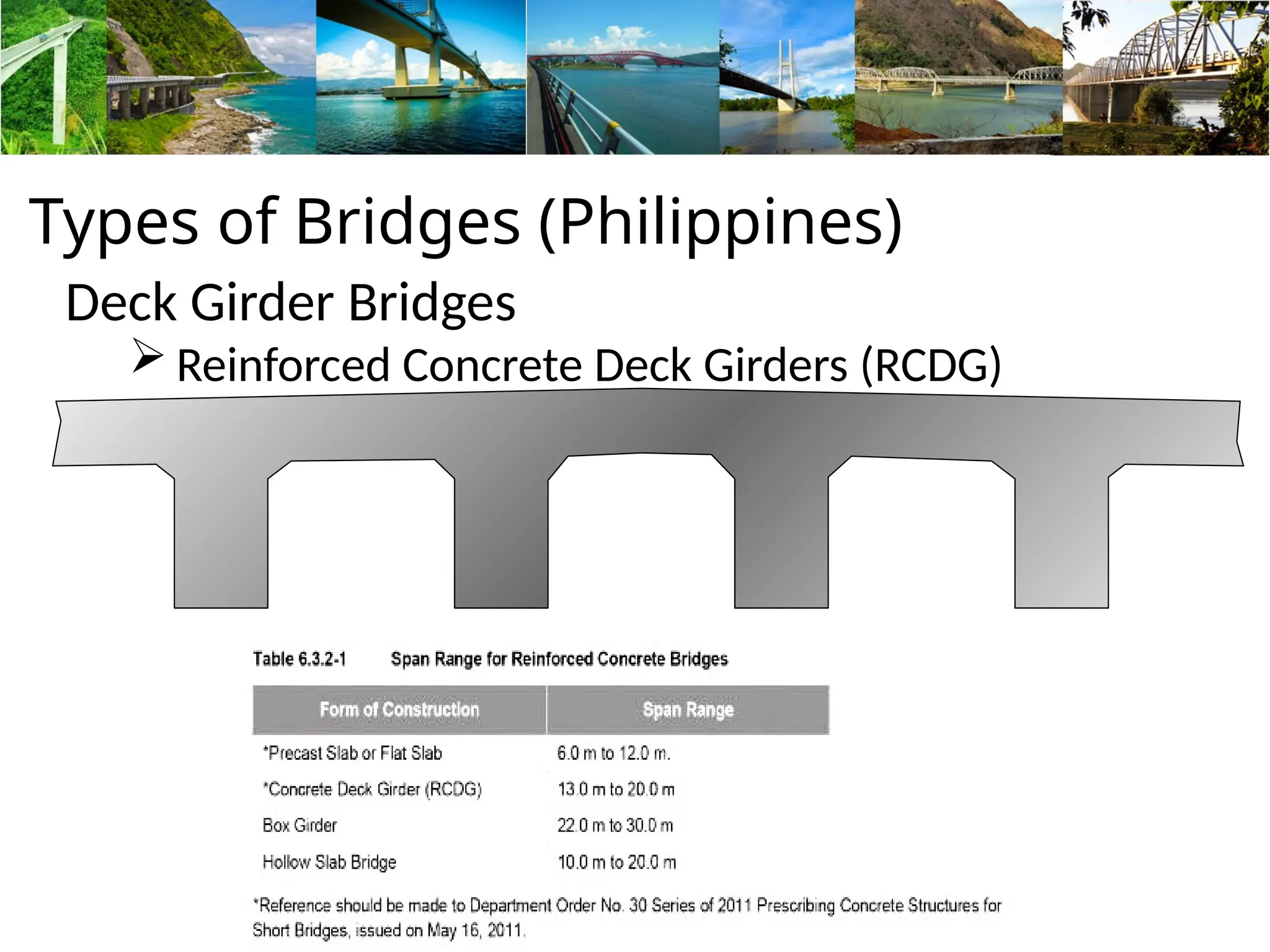

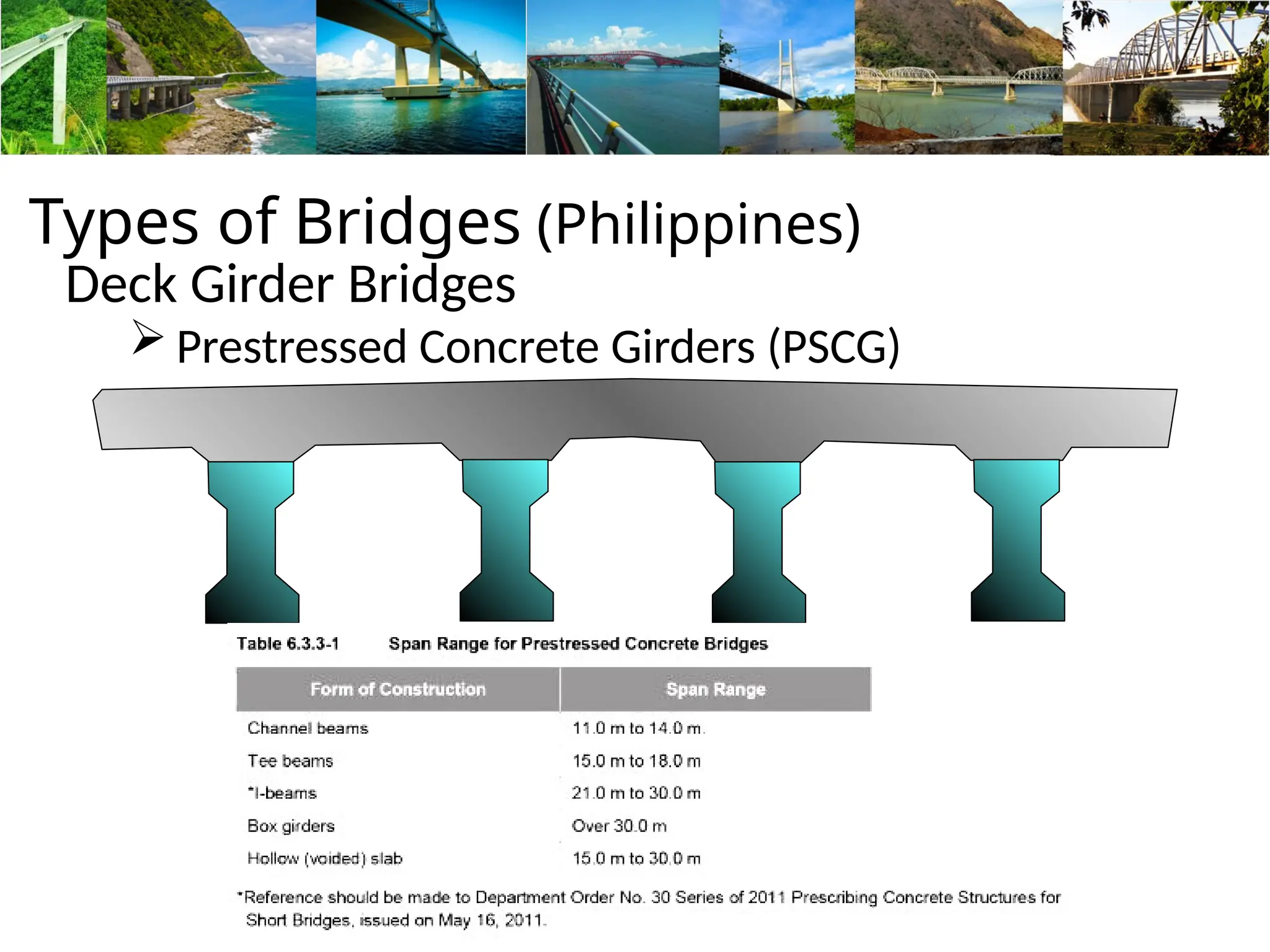

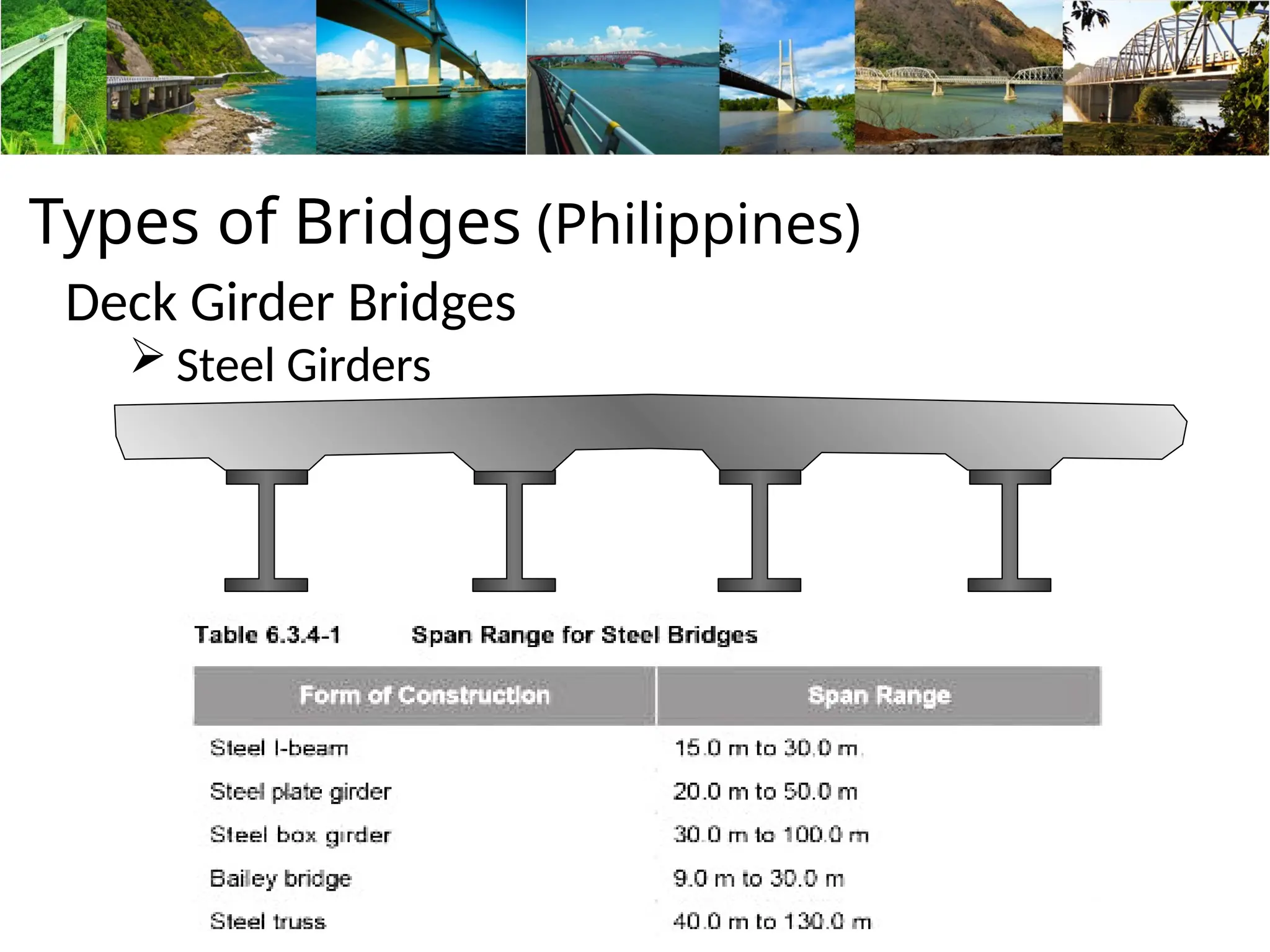

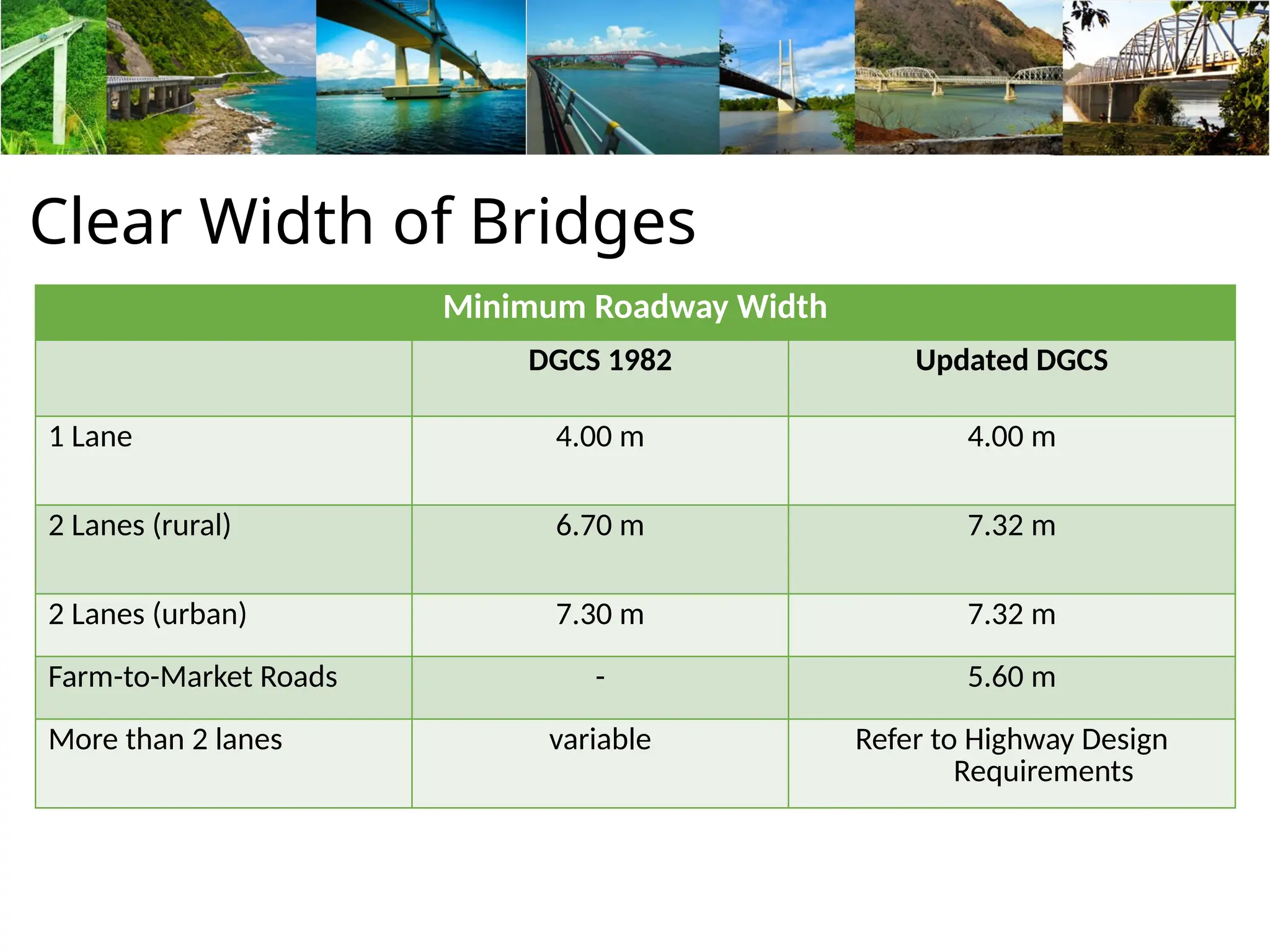

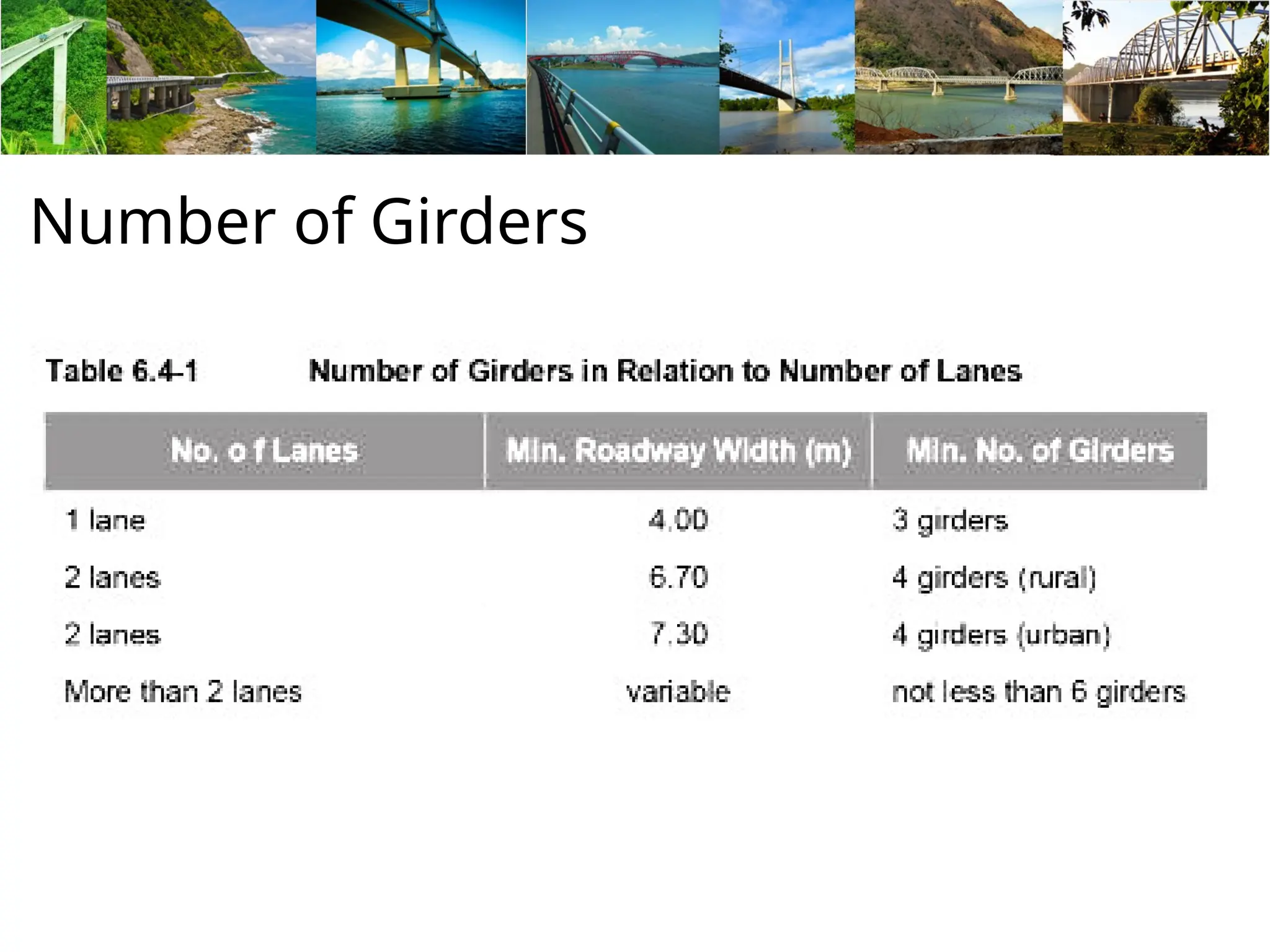

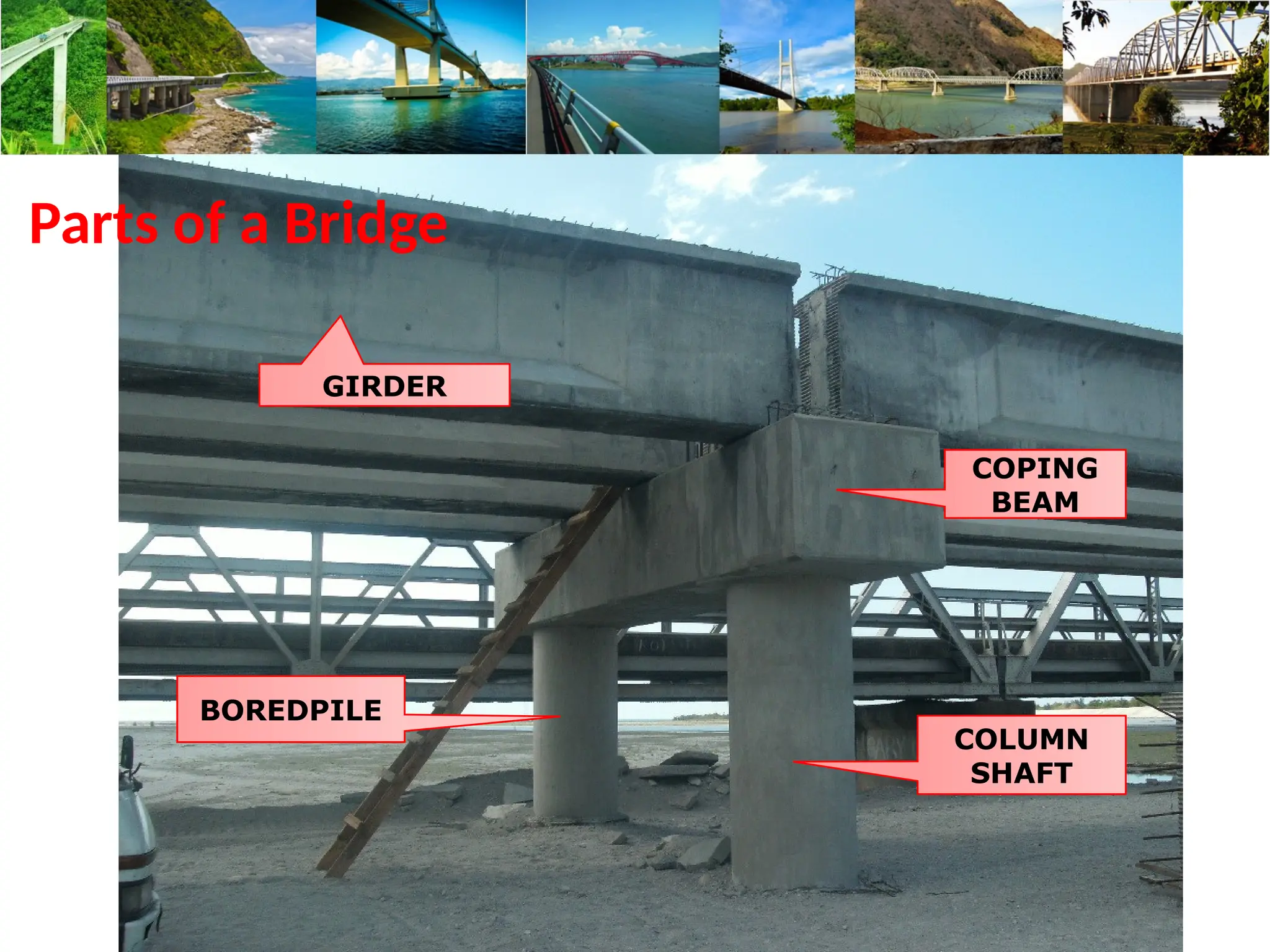

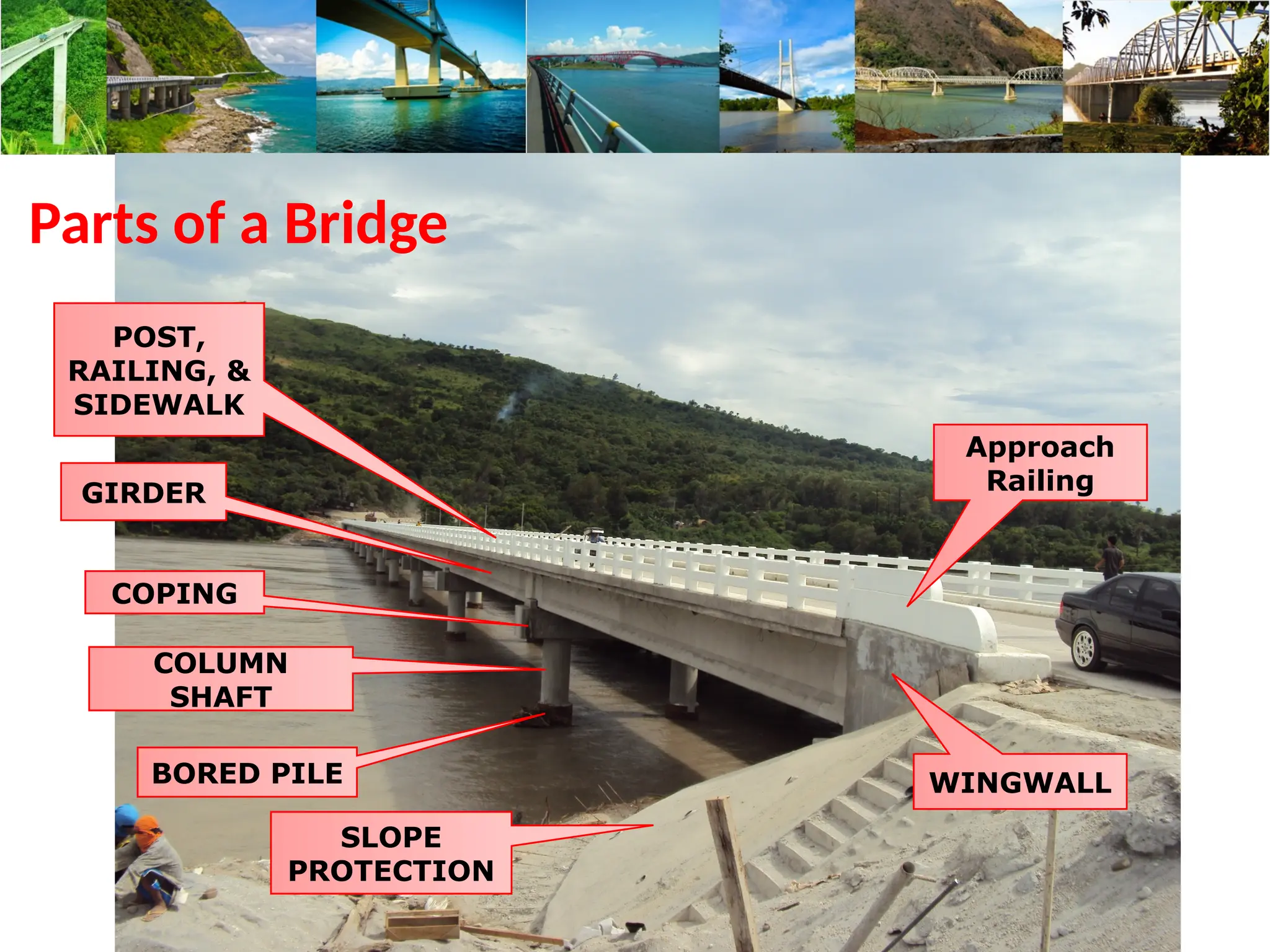

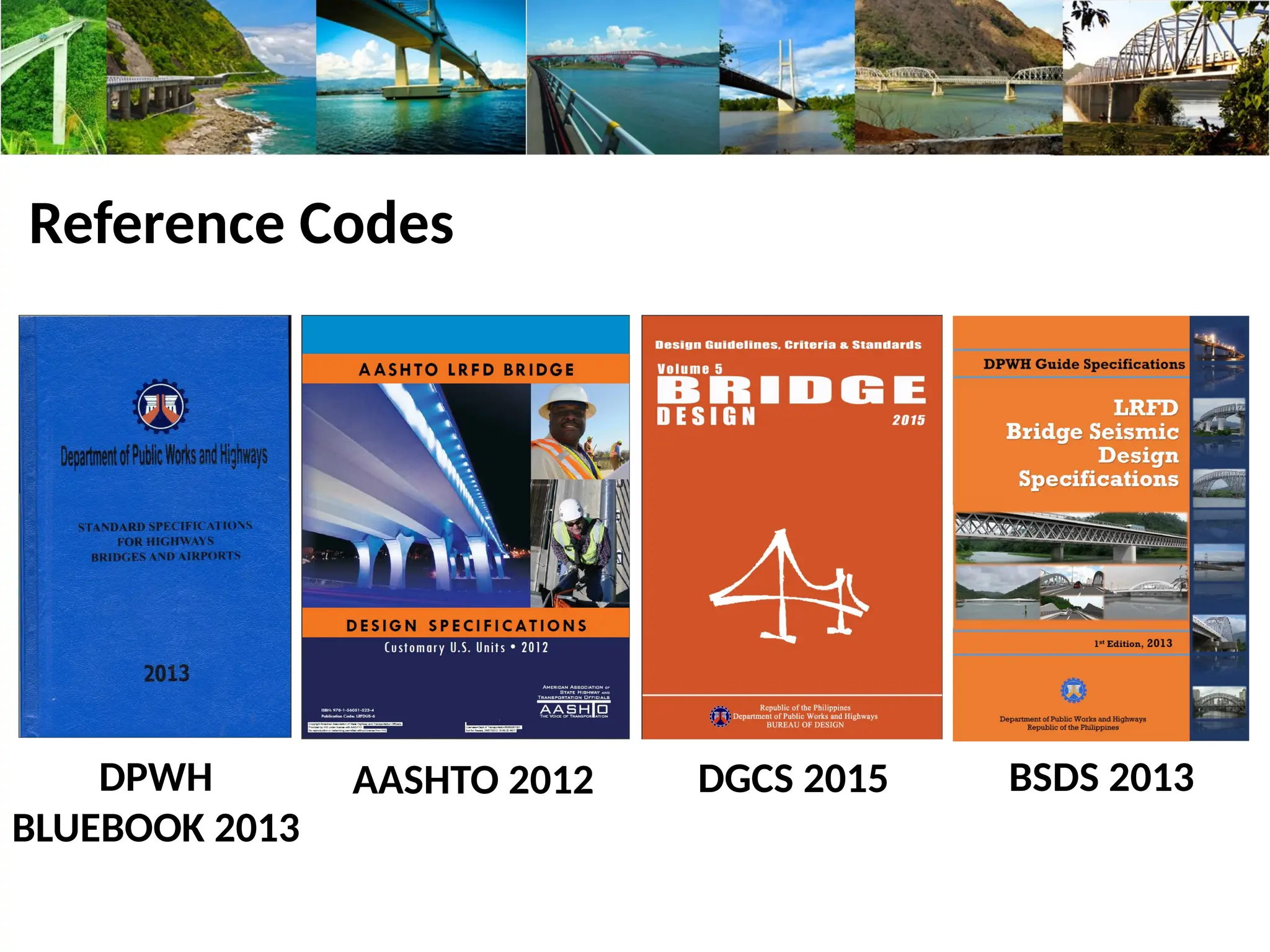

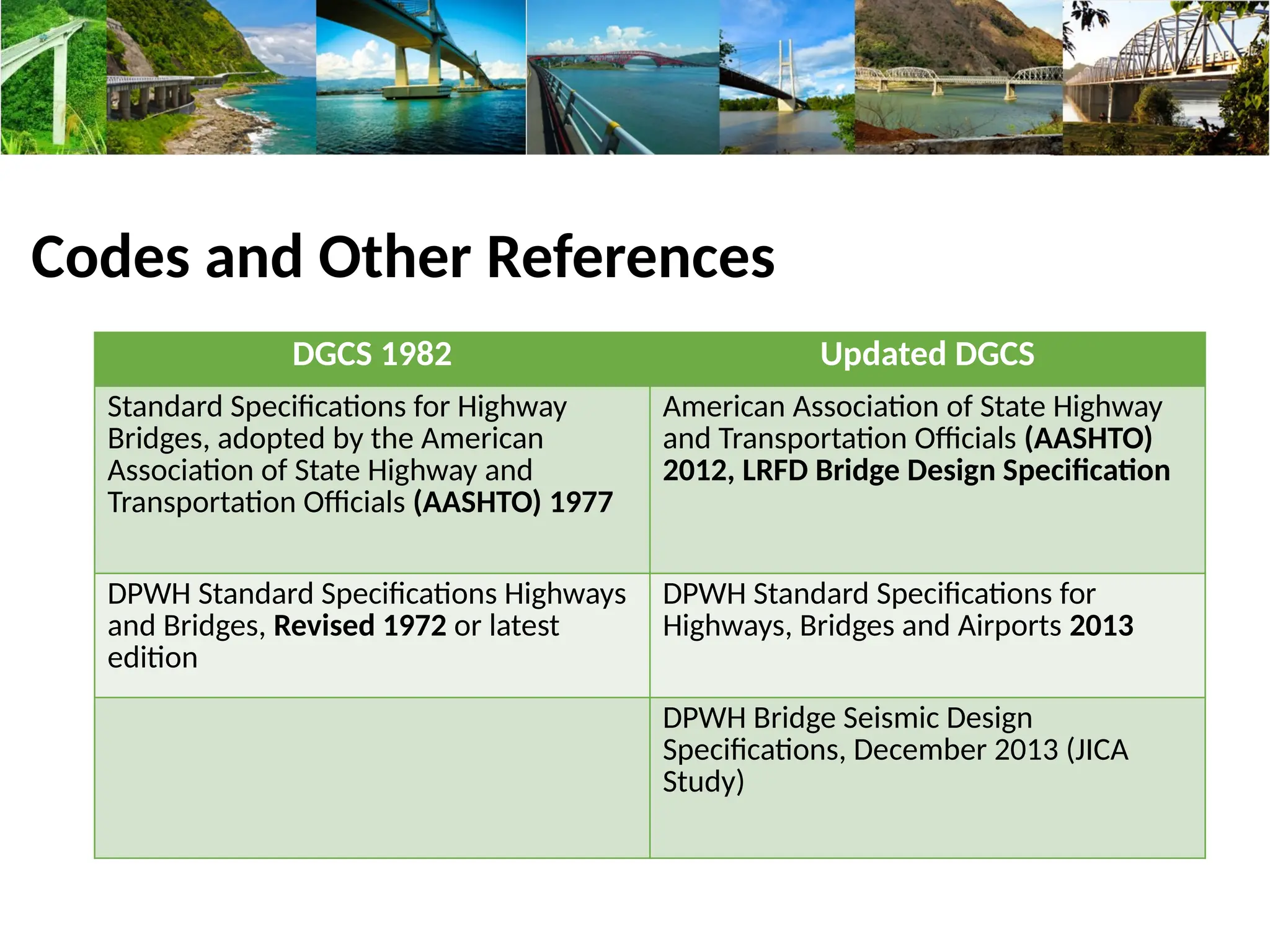

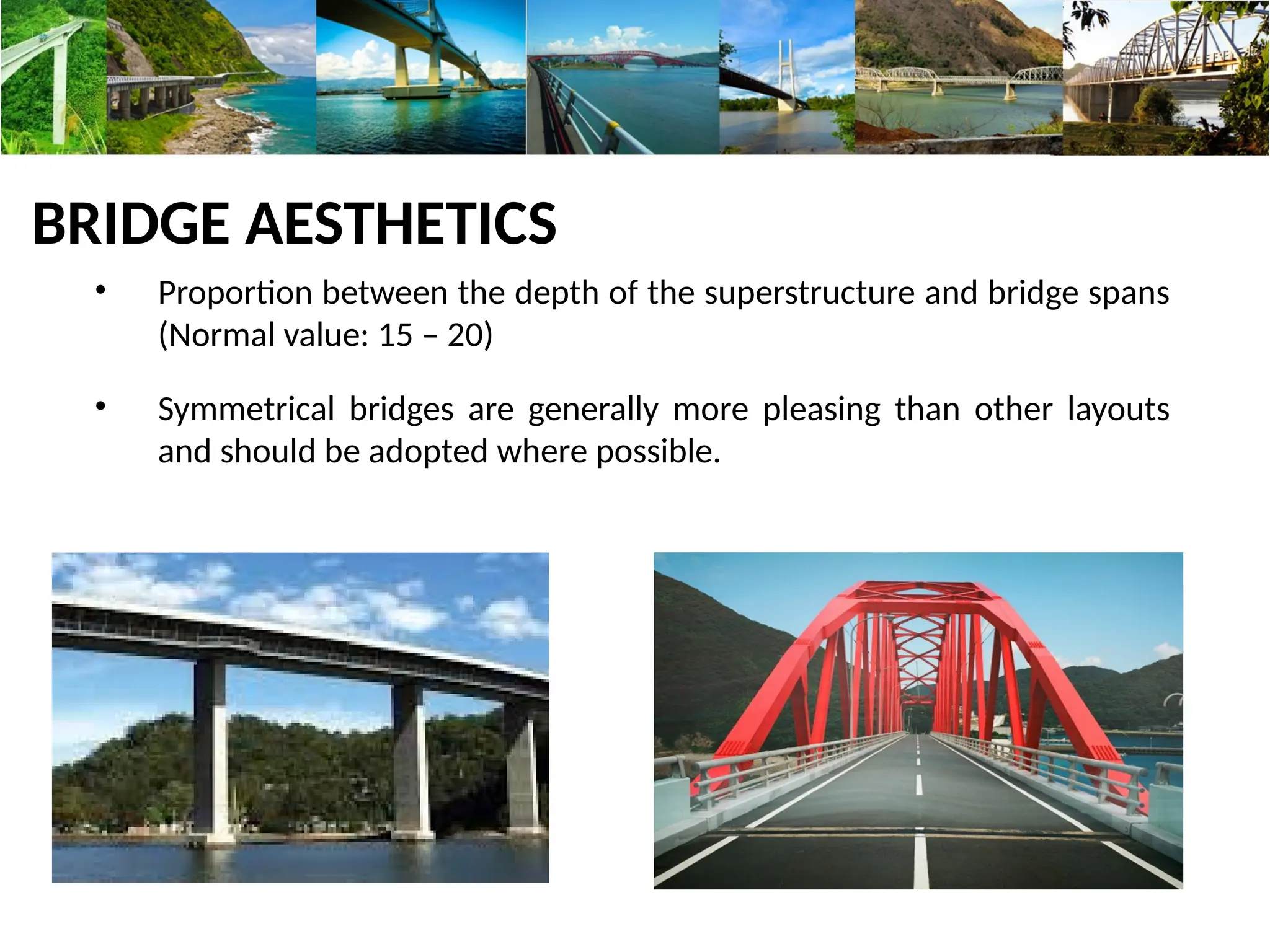

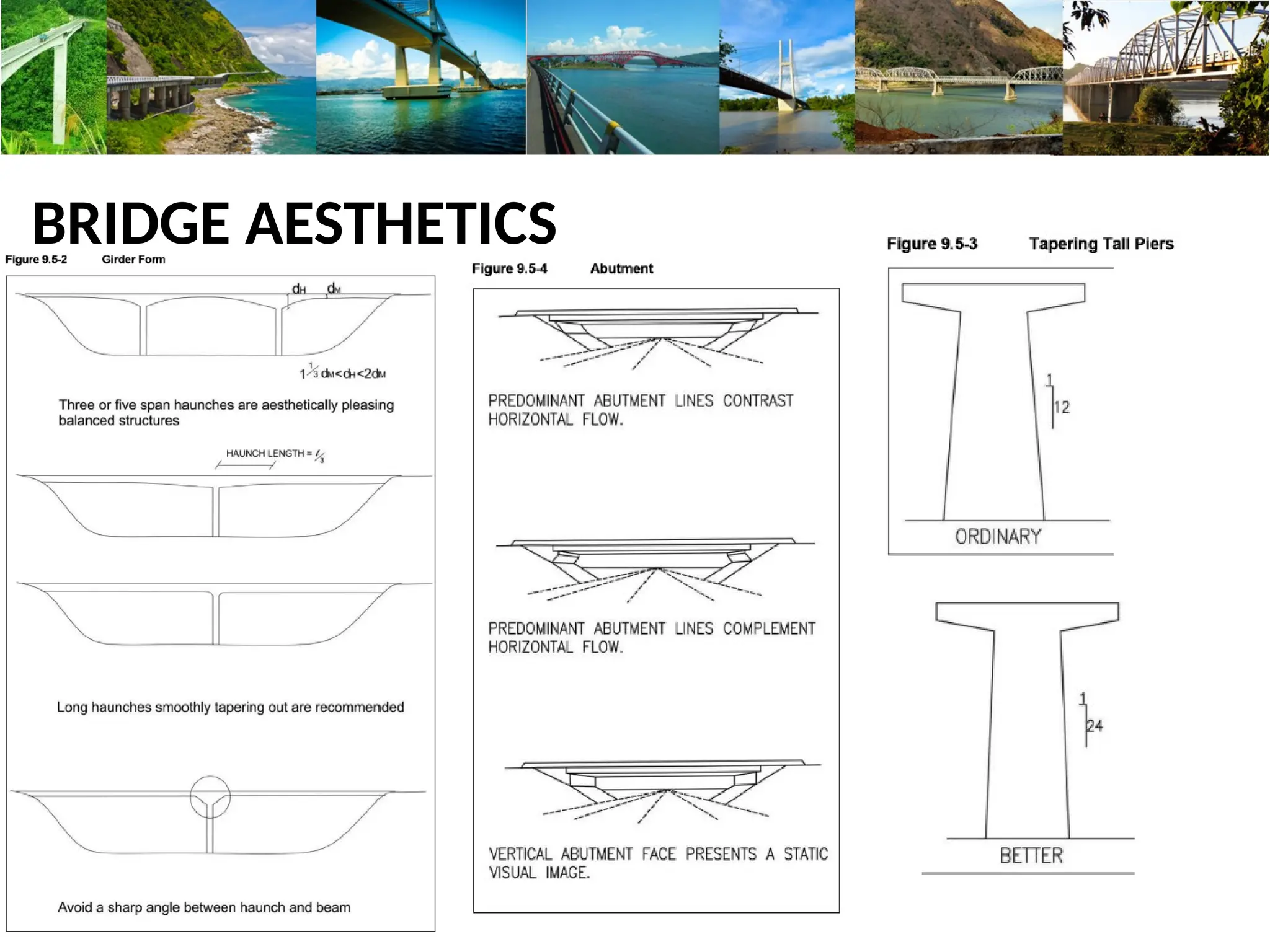

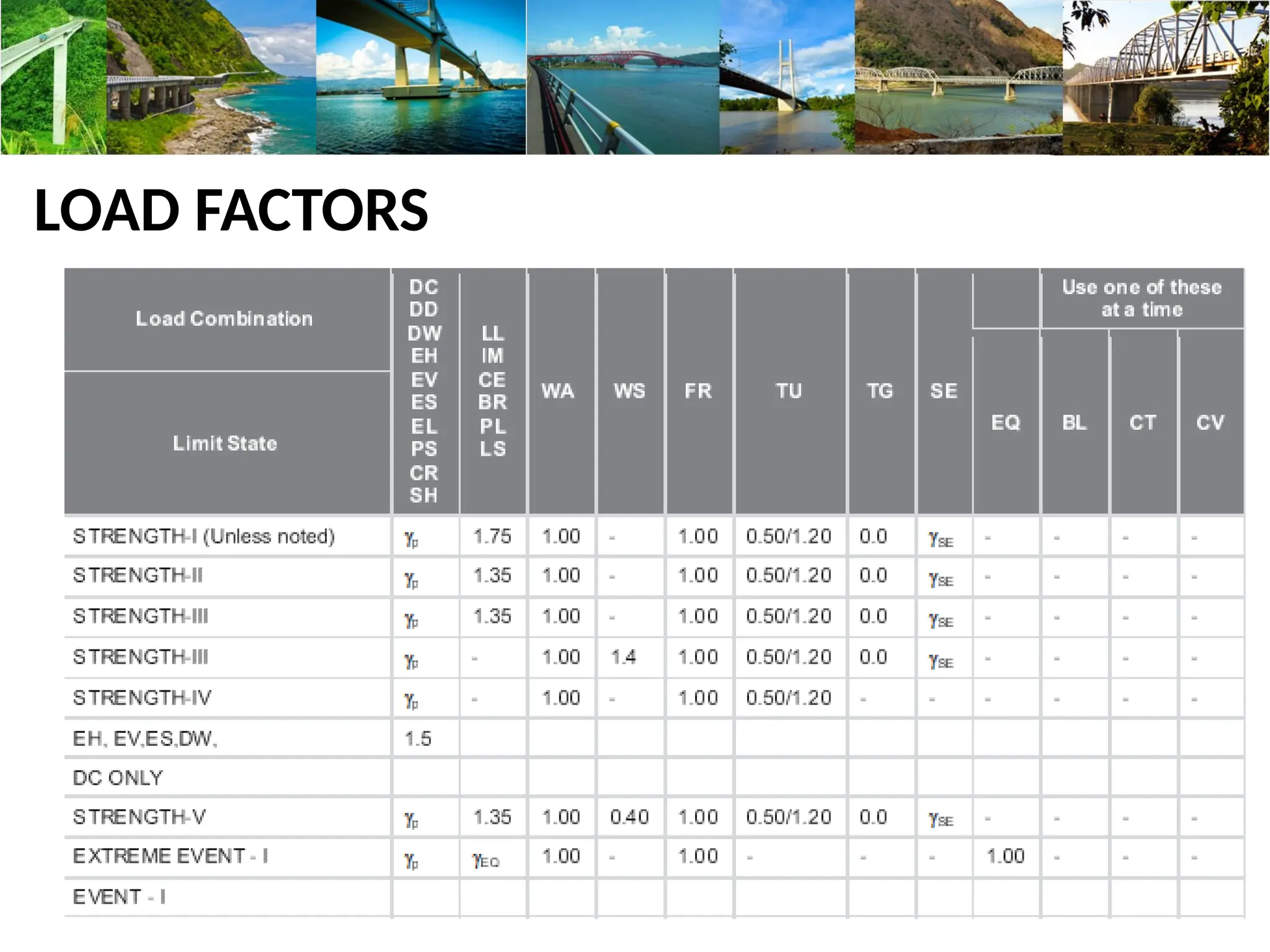

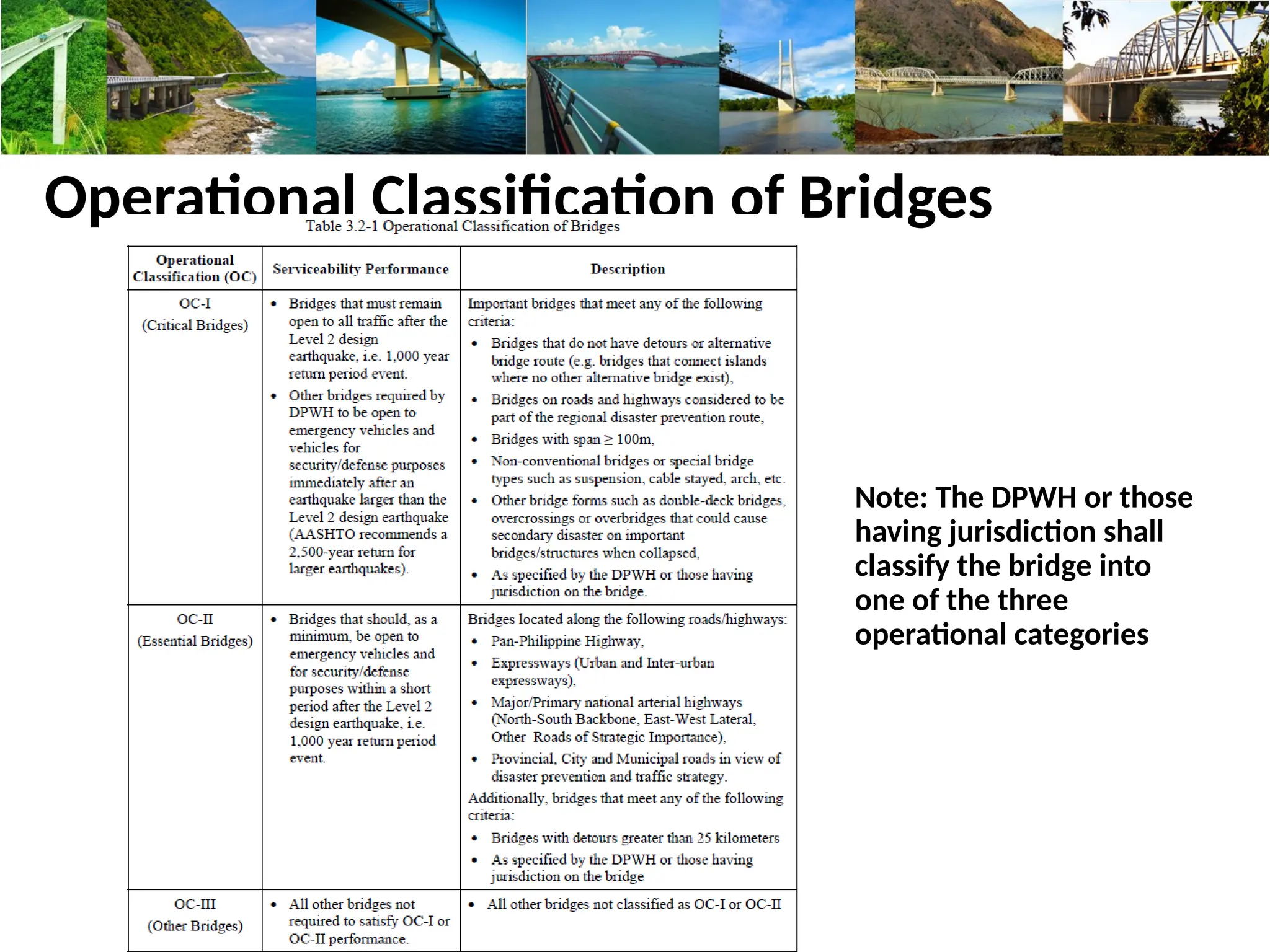

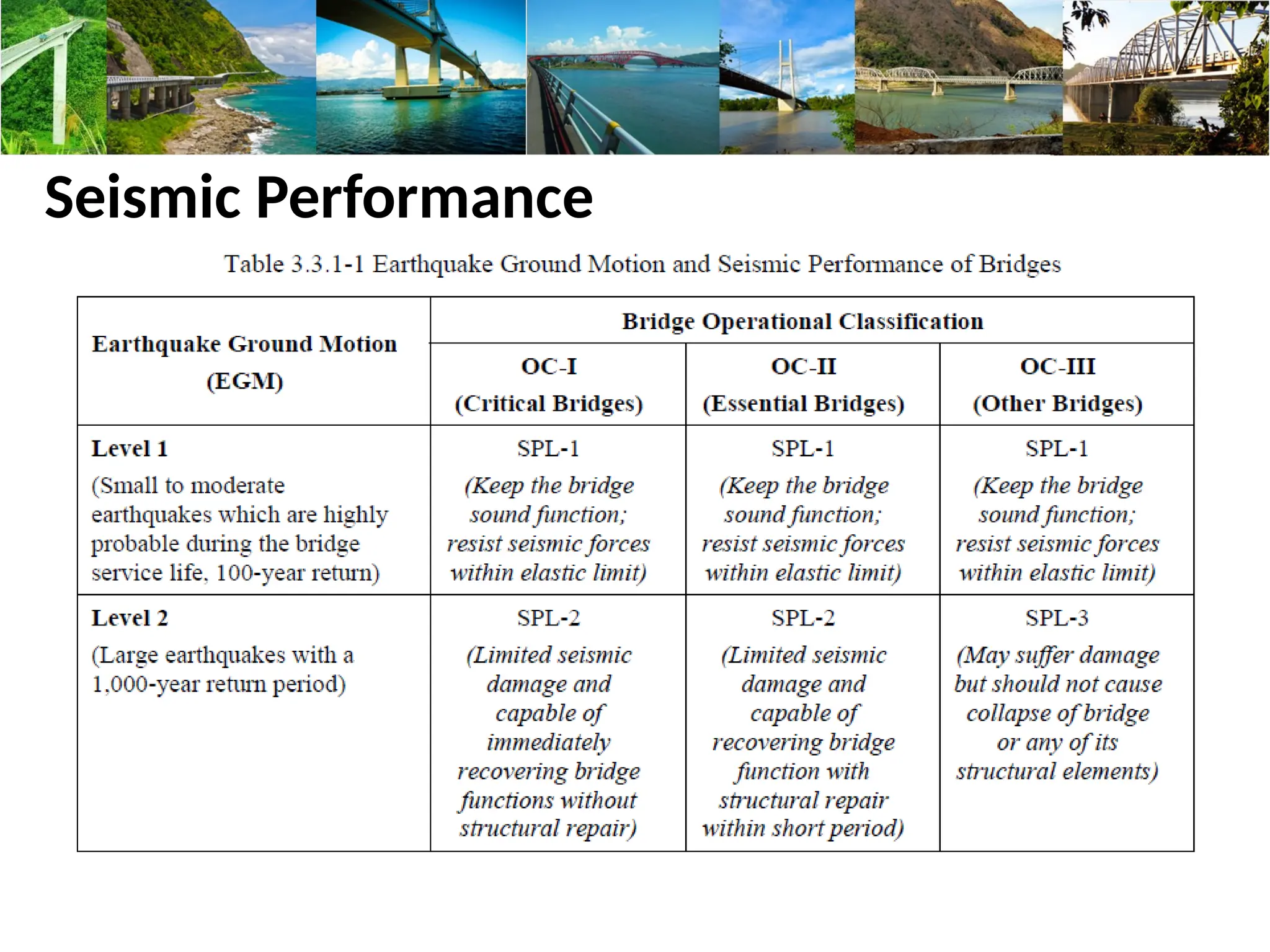

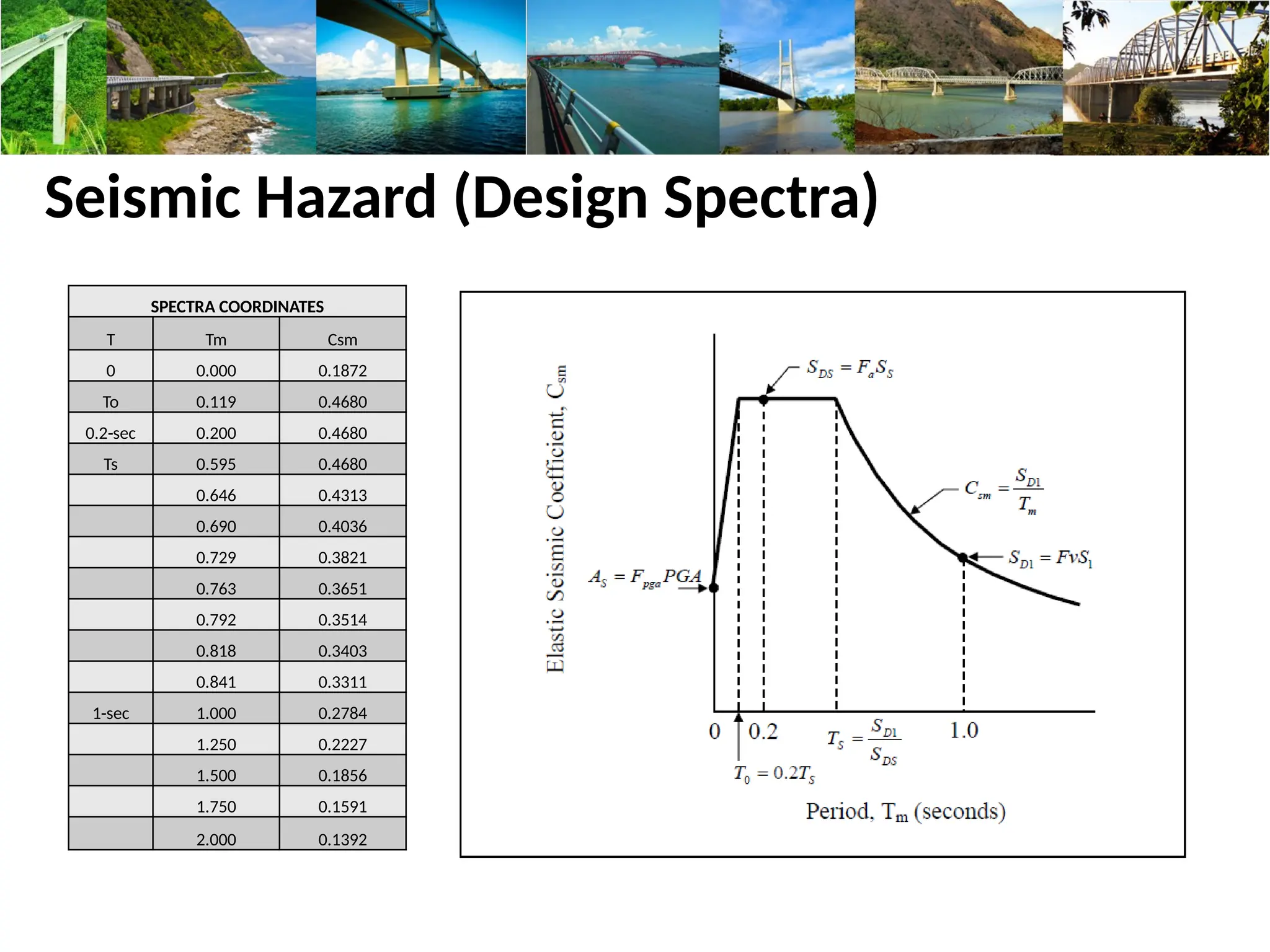

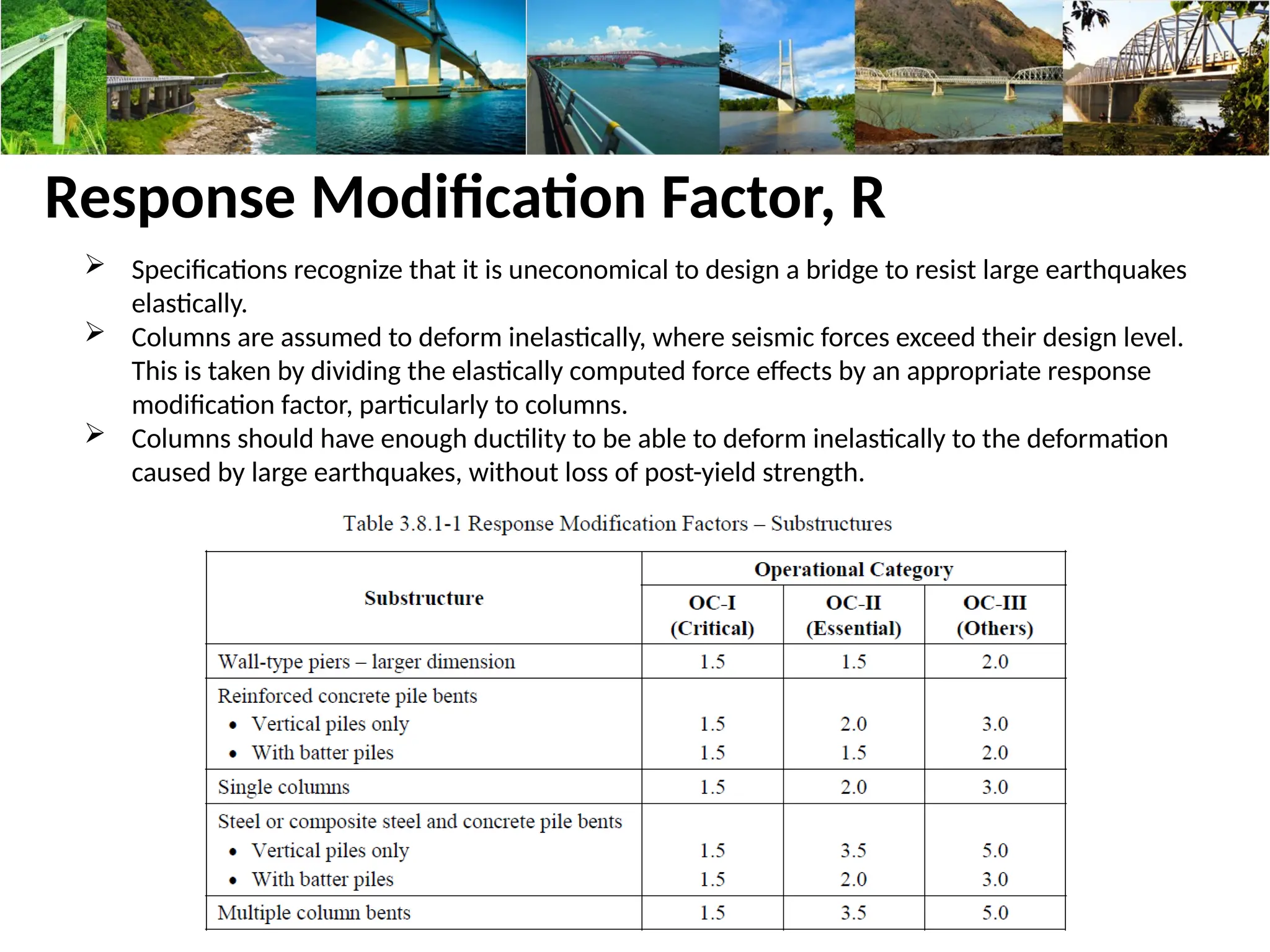

The seminar covered bridge design parameters, including types of bridges, construction methods, and design philosophies. Key topics included classifications of bridges based on materials, usage, and design systems, as well as necessary design requirements and aesthetics. Additionally, the document outlined relevant codes and specifications that guide the construction and seismic design of bridges in the Philippines.