This document describes the design and development of an open differential for an all-terrain vehicle (ATV). The authors first perform analytical calculations to determine the required gear ratios and sizes based on the vehicle's dimensions and performance requirements. They select materials and design the gears to withstand bending and contact stresses. Bearings are sized to support the radial and axial loads from the gears. The differential components, including gears, pinion, and center pin, are then modeled in CAD software. In summary, the authors designed and analyzed an open differential through calculations and CAD modeling to transmit torque from the transmission to the wheels of an ATV.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 05 Issue: 12 | Dec 2018 www.irjet.net p-ISSN: 2395-0072

© 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 419

F) Ratio(D/E) = 10.27/6.79 = 1.53,

Hence outer wheel rotates 1.53 times faster than inner

wheel.

Reduction between spider gears and side gears

= 1.53

= 1.8 (considering available modules.)

2.2 Material Selection for Gears

Table-1: Material Selection Chart

Material

Properties

20MnCr5

Steel

EN 8 Steel EN19 Steel

Tensile

yield

Strength

(Mpa)

750 433 470

Tensile

ultimate

Strength

(Mpa)

1000 650 745

Density

(kg/m3) 7850 7800 7800

Hence considering more tensile strength and more ultimate

strength with optimum material cost, 20MnCr5 steel was

finalized as gear material.

2.3 Gear Teeth Calculations

Fig-3: Bevel gear terminology

Assuming,

Pitch circle diameter of gear (Dg) = 72mm

No. of teeth on gear (Zg) = 18,

Pitch circle diameter of pinion (Dp) = 40mm

No. of teeth on pinion (Zp) = 10

Reduction = 1.8, Module = 4mm,

Addendum (ha)= 4mm, dedendum (hf)= 5mm (According

to stub involute profile)

According to design data book,

Material used = 20MnCr5,

Syt = 750Mpa

Sut = 1000Mpa.

Case hardness = 42HRc (Material to be case hardened for

pinion only.)

Pitch cone angles are,

γp = tan-1 (zp/zg)ASD

γp = tan-1 (10/18)

=29.05°

γg =60.95°

Beam strength (σb) = sut/3

=1000/3

(σb) =333.33N/mm^2

Virtual number of teeth on pinion (Z`p)

= Zp/cos (γp)

=10/cos(29.05)

Z`p = 11.439

Similarly,

Virtual number of teeth on gear (Z`g) = 37.069

The pinion is designed considering bending,

Dp = m*Zp

= 4*10

Dp = 40mm

Similarly,

Dg = 72mm

Pitch cone distance (Ao) =√(dp/2)^2+(dg/2)^2

=√40/2)^+(72/2)^

Ao = 41.182mm

Lewis form factor (Y`p) = 0.55-(2.64/z`)

= 0.55-(2.64/11.439)

∴ (z` is 20 for stub involute profile)

Y`p = 0.3192

Beam strength (Fb) = σb *b*m*Y`p[1-(b/Ao)]

=333.33*13.727*4Z*0.3192[1-(13.727/41.182)]

Fb=3894.768N

Ratio factor (Q`) = 2*Z`g/ (Z`p+Z`g)

= 2*37.069/ (11.439+37.069)

Q`= 1.5283

Load stress factor (K) = 0.16[BHN/100]^2

= 0.16[400/100]^2

K = 2.56N/mm^2

Wear strength (Fw)= 0.75*dp*b*Q*K/[cos(γp)]

=0.75*40*13.727*1.5283*2.56/0.8742

Fw=1843.047N

As,Fb>Fw; Gear pair is designed for pitting.

V= *dp*np/(60*1000)

=π*40*1080/(60*1000)

V=2.2619m/s

Tangential force (Ft) = P/V

= 12000/2.2619

Ft = 5305.165N

Velocity factor(Kv) = 6/(6+V)

= 6/(6+2.2619)

Kv = 0.72622

Effective load (Feff) = Ka*Km*Ft/Kv

= 1.25*1*5305.165/0.72622

Feff = 9131.40N

Hence, to avoid pitting failure we consider factor of safety of

1.75](https://image.slidesharecdn.com/irjet-v5i1280-181229053311/75/IRJET-Design-and-Development-of-Open-Differential-for-Transmission-System-of-Quad-Bike-2-2048.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 05 Issue: 12 | Dec 2018 www.irjet.net p-ISSN: 2395-0072

© 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 420

Fw = Nf * Feff

= 1.75*9131.40

Fw = 15979.958N

Mean radius of bevel pinion (rmp)

=(dp/2)-[b*sin(γp)/2]

= (40/2)-[13.727*sin(29.05)/2]

rmp = 16.6672 mm

Similarly,

Mean radius of bevel gear (rmg)=29.99mm

According to IS grade 6, pitch error is given by the equation,

e = 8.0+0.63[m+0.25*√rm]

For pinion, ep =8.0+0.63[m+0.25*√rmp]

=8.0+0.63[4+0.25*√2*16.6672

ep = 11.429 m

Similarly,

For gear,eg =11.739µm

Pitch error on meshing teeth © = ep + eg

=11.426+11.72

e=23.168*10^-3mm

Ftmax = Ka*Km*Ft

= 1.25*1.* 5305.165

Ftmax = 6631.456N

For steel pinion and steel gear deformation factor is given

by,

C = 11000*e

= 11000*30*10^-3

C = 330N/mm

By using Buckingham’s equation, dynamic loading is given

by,

Fd = 21*V*(bC+Ftmax)/[21V+√bc+Ftmax]

=21*2.2619*(13.727*330+6631.456)/[21*2.2619+ 13.727*

330+6631.456]

Fd = 3461.79N

Feff = Ka*Km*Ft+Fd

= 1.25*1*5305.165+3247.176N

Feff = 10093.25N

Nf = Fw/Feff

=23997.64/12392.13

Nf= 1.583

Hence, design is safe

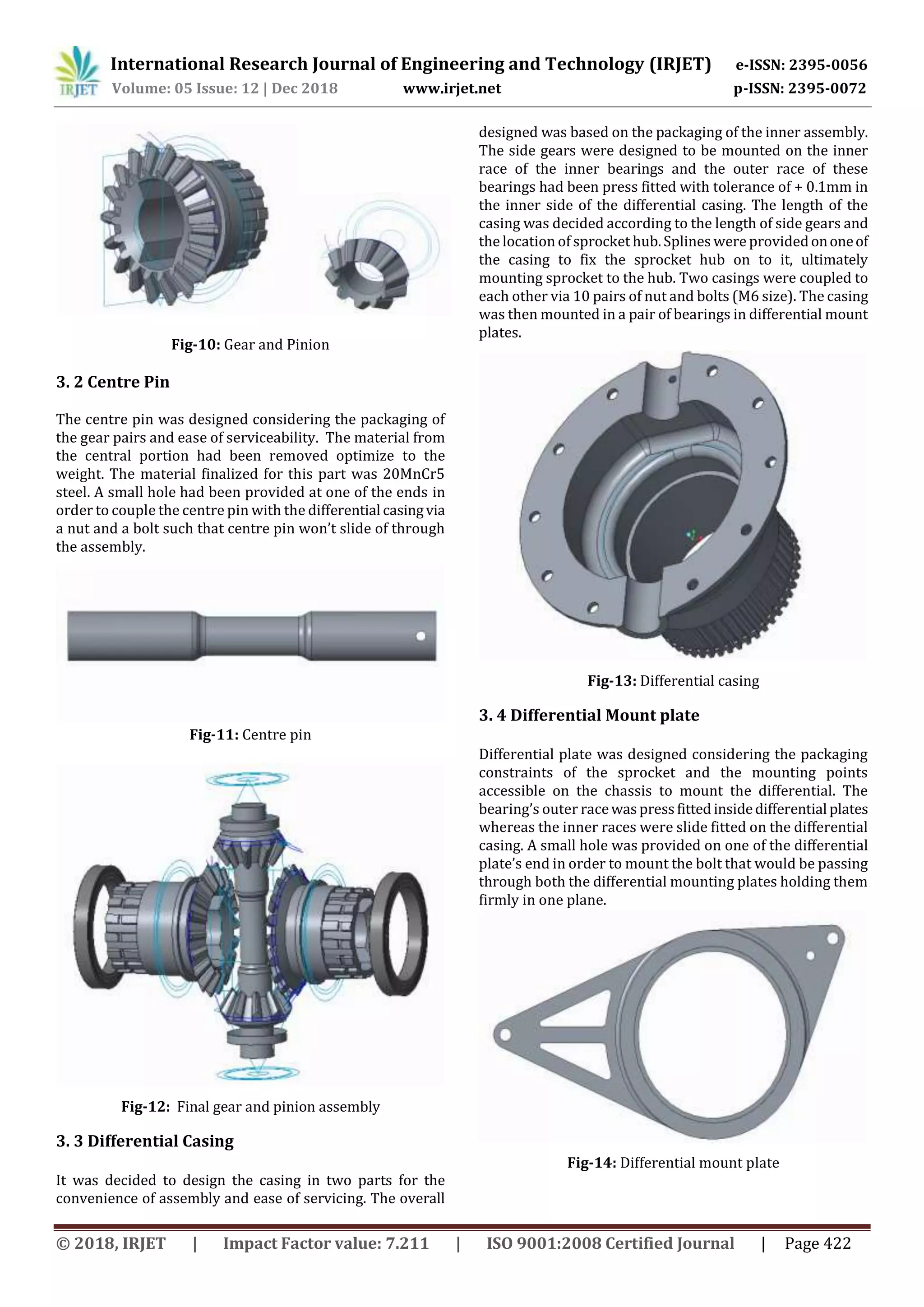

2.4 Bearing Calculations

Inner Bearings :

Fig-4: Free body diagram of differential

Forces on gear:-

Ft =p/v

=12*10^3/2.26

Ft =5305.16N

Radial forces on gear:-

Frp = Ft*tan (ϕ)*cos(γp)

=5305.16*tan(20)*cos(29.05)

Frp =1688N

Frg=Ft*tan(ϕ )cos(γg)

=5305.16*tan(20*cos(60.95)

Frg=937.602N

Axial forces on gear:-

Fag=Ftm*tan(ϕ)*sin(γp)

=5305.16*tan(20)*sin(29.05)

Fap=937.602N

Fag=Ftm*tan(ϕ)*sin(γp)

=5305.16*tan(20)*sin(60.95)

Fag=1688N

=5305.16*2.26

Resultant load on bearing:

Fig -5: Vertical loading diagram

Moment about A:

(Rbv*80)+(957.602*20)+(20*40)-(957.602*60)=0

Rbv = 468.801N

Similarly moment about B gives;

Rav = -448.801N

Fig -6: Horizontal loading diagram

Moment about B:

(Rah*80)+(5305.16*60)-(1688*36)-

(5305.16*20)+(1688*36)=0

Rah = -2652.58N

Rah = 103.782652.58N

Resultant load on bearing:

Ra= 2690.279 N

Rb=2693.68 KN

Lh10=12000

n = 600](https://image.slidesharecdn.com/irjet-v5i1280-181229053311/75/IRJET-Design-and-Development-of-Open-Differential-for-Transmission-System-of-Quad-Bike-3-2048.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 05 Issue: 12 | Dec 2018 www.irjet.net p-ISSN: 2395-0072

© 2018, IRJET | Impact Factor value: 7.211 | ISO 9001:2008 Certified Journal | Page 425

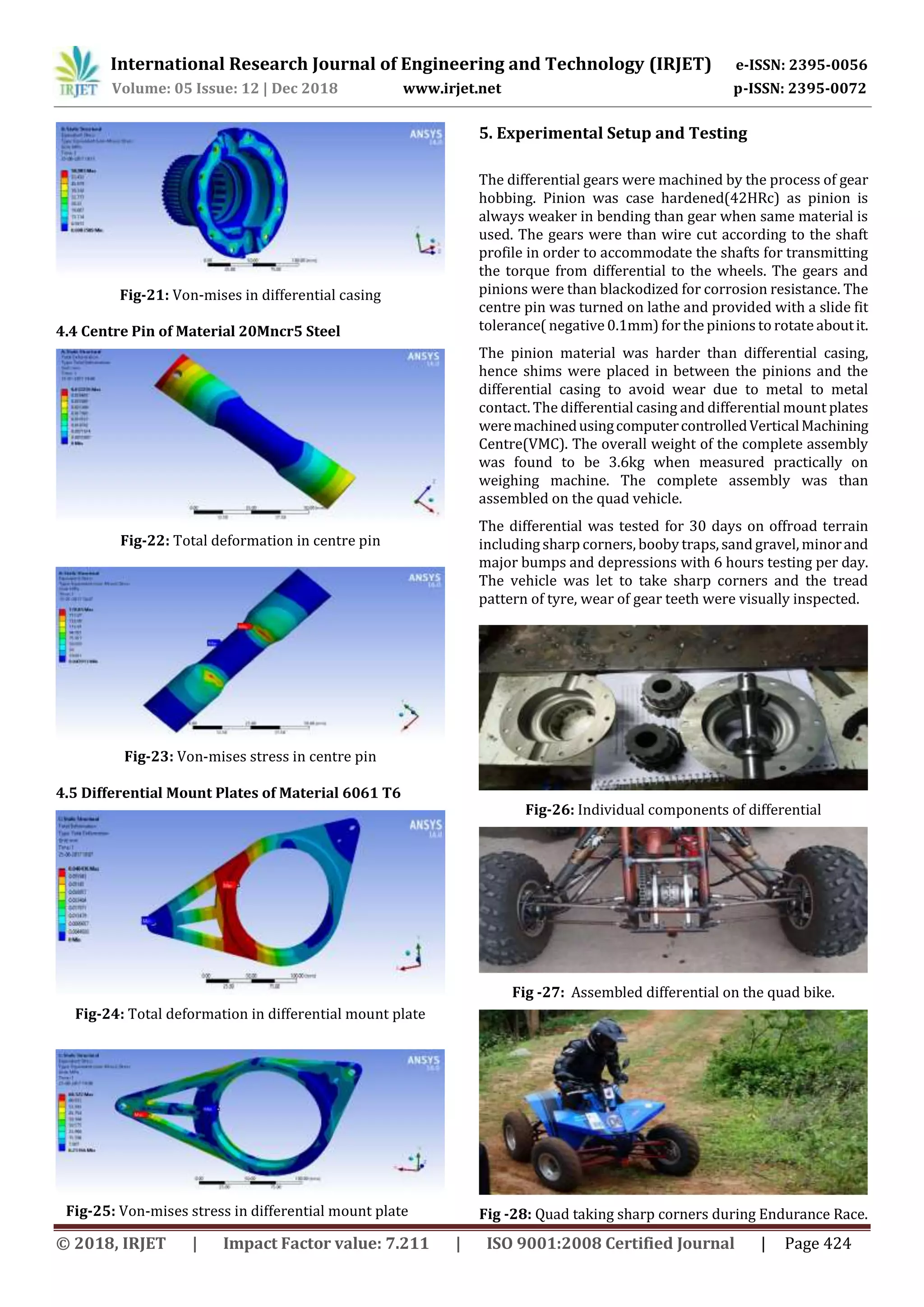

6. CONCLUSION

The differential assembly, after implementation in quad

vehicle, satisfies the design requirements. It proves to be

durable on rough terrain and critical operating conditions.

No traction difference problem was observed and vehicle

could maneuver sharp turns without losing traction. Thus,

we can conclude that initial objective of differential for

transmission system of quad vehicle is satisfied and serves

as ground for further research on said system.

7. REFERENCES

[1] Milliken and Milliken, Race Car Vehicle Dynamics.

[2] C. Smith, “Tune to Win”, AERO publishers Inc.

[3] V.D. Kodgire, ‘Material Science and Metallurgy’

[4] V.B. Bhandari, ‘Design of Machine Elements’](https://image.slidesharecdn.com/irjet-v5i1280-181229053311/75/IRJET-Design-and-Development-of-Open-Differential-for-Transmission-System-of-Quad-Bike-8-2048.jpg)