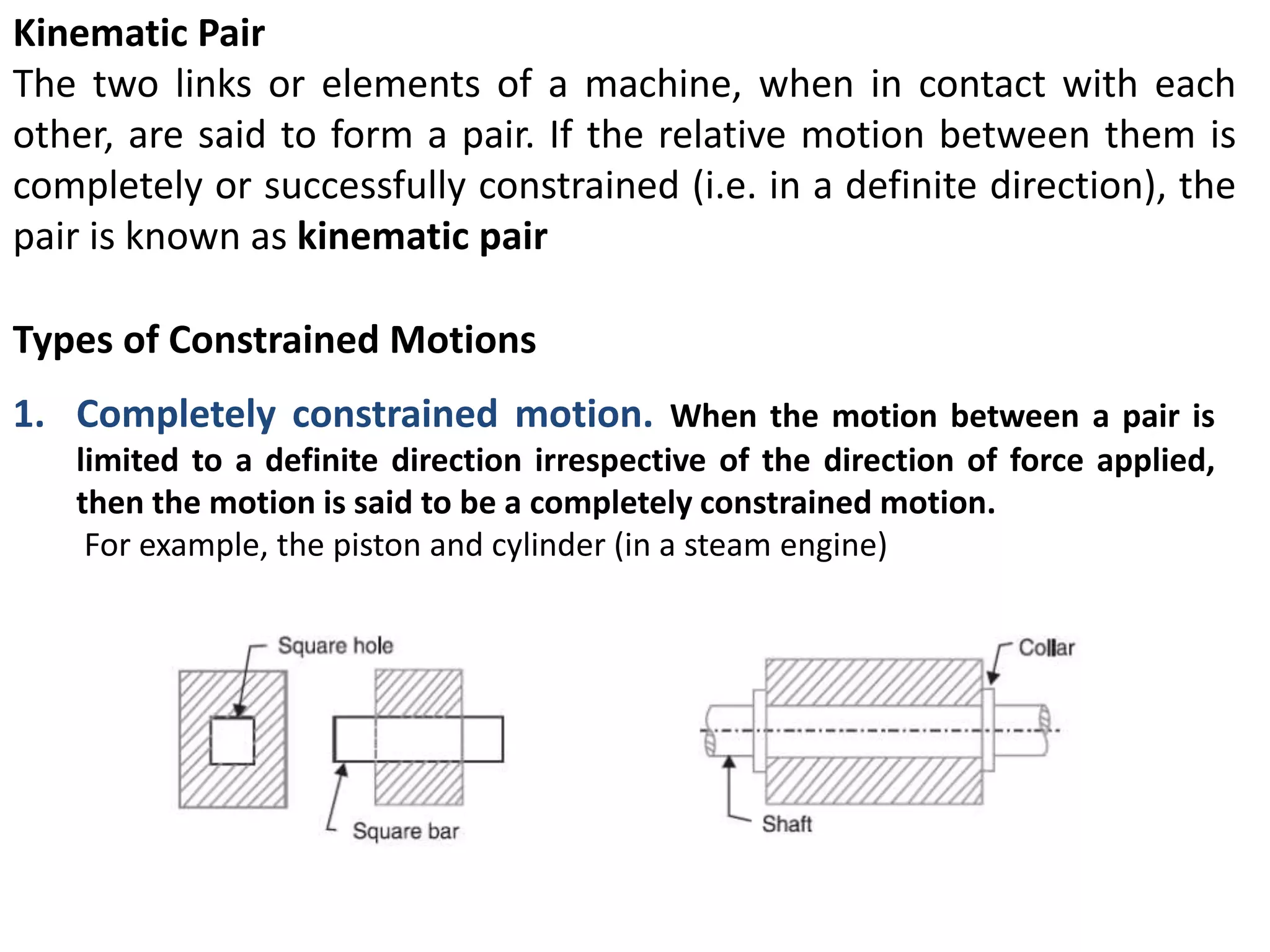

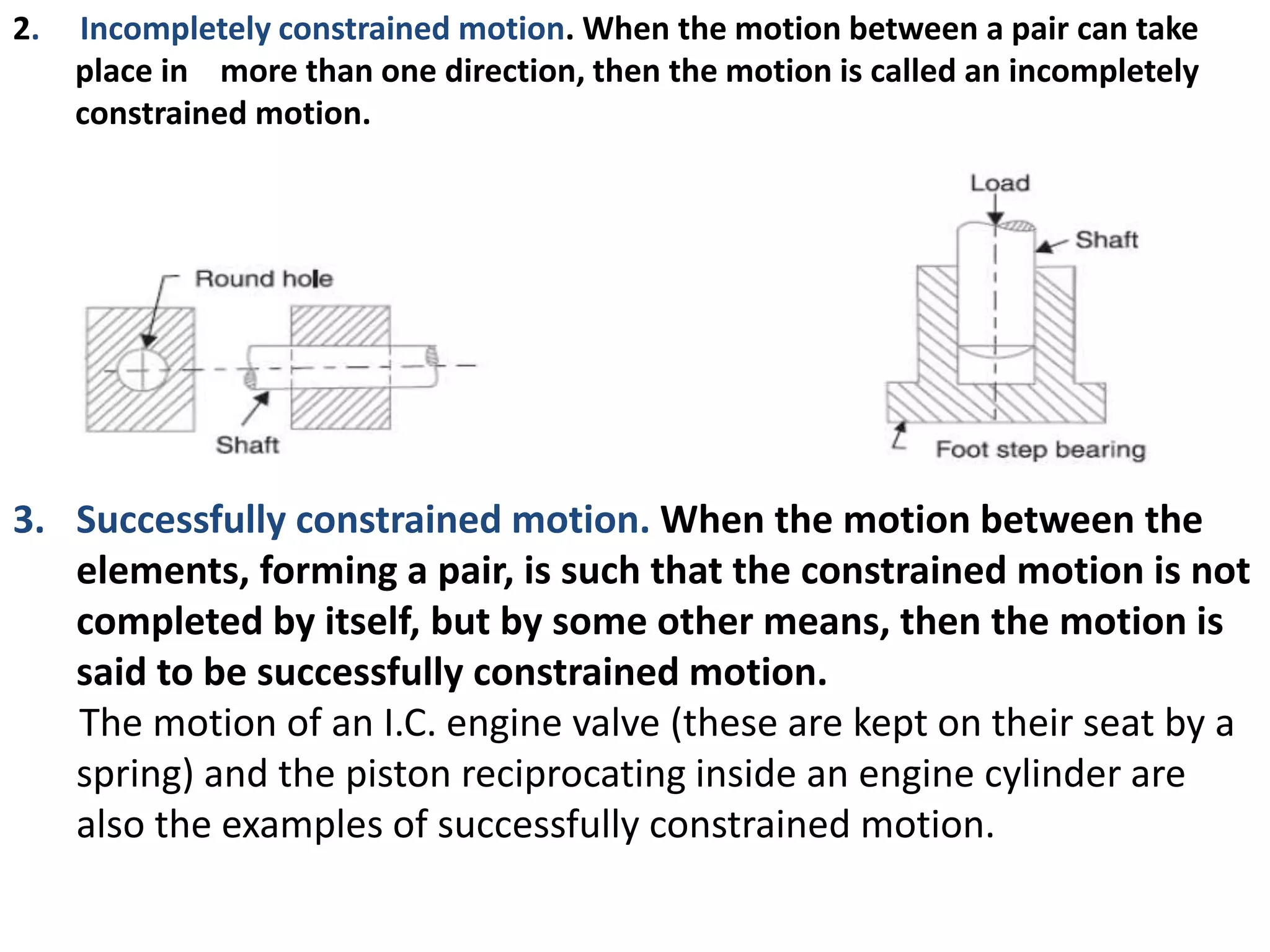

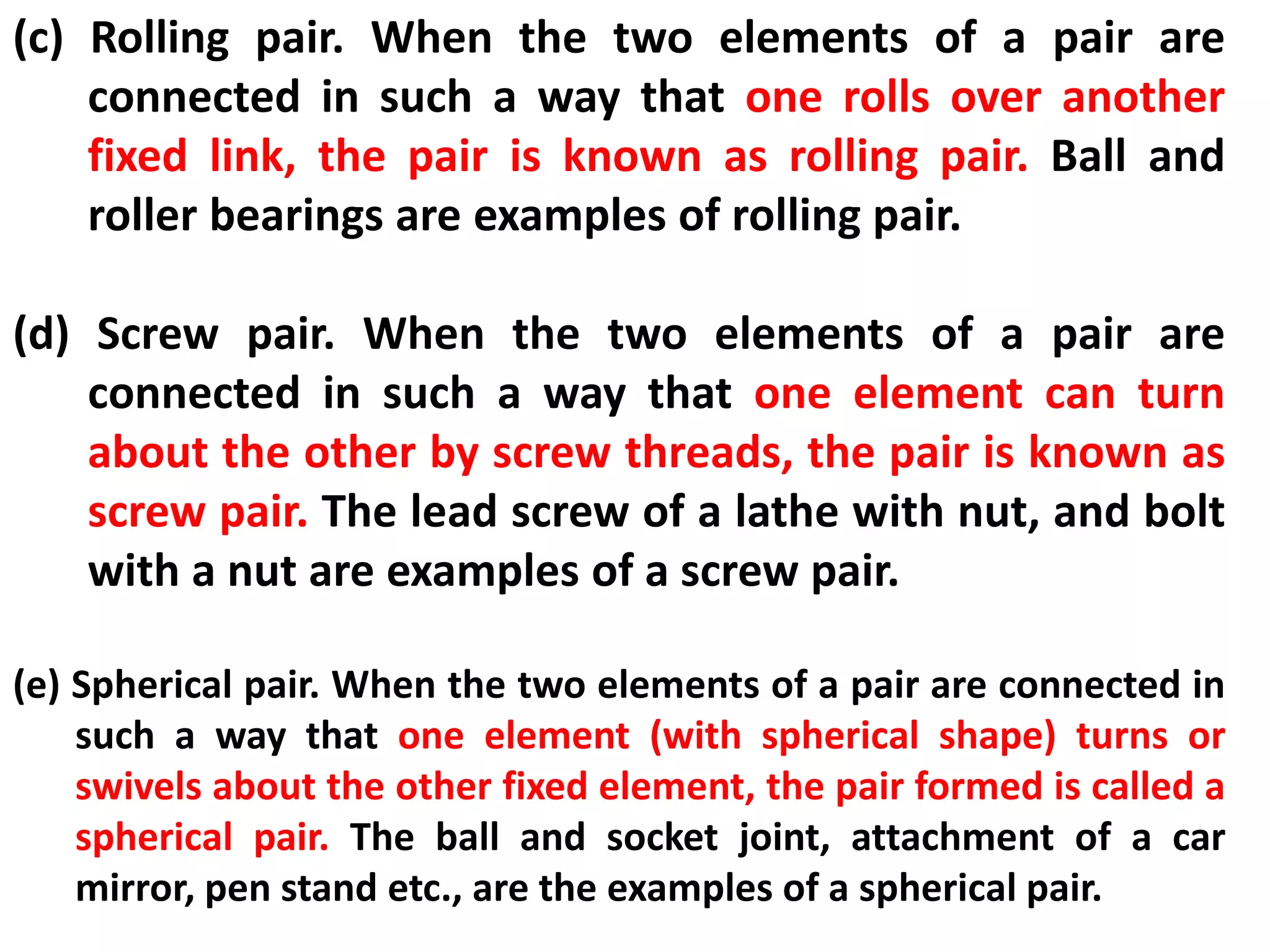

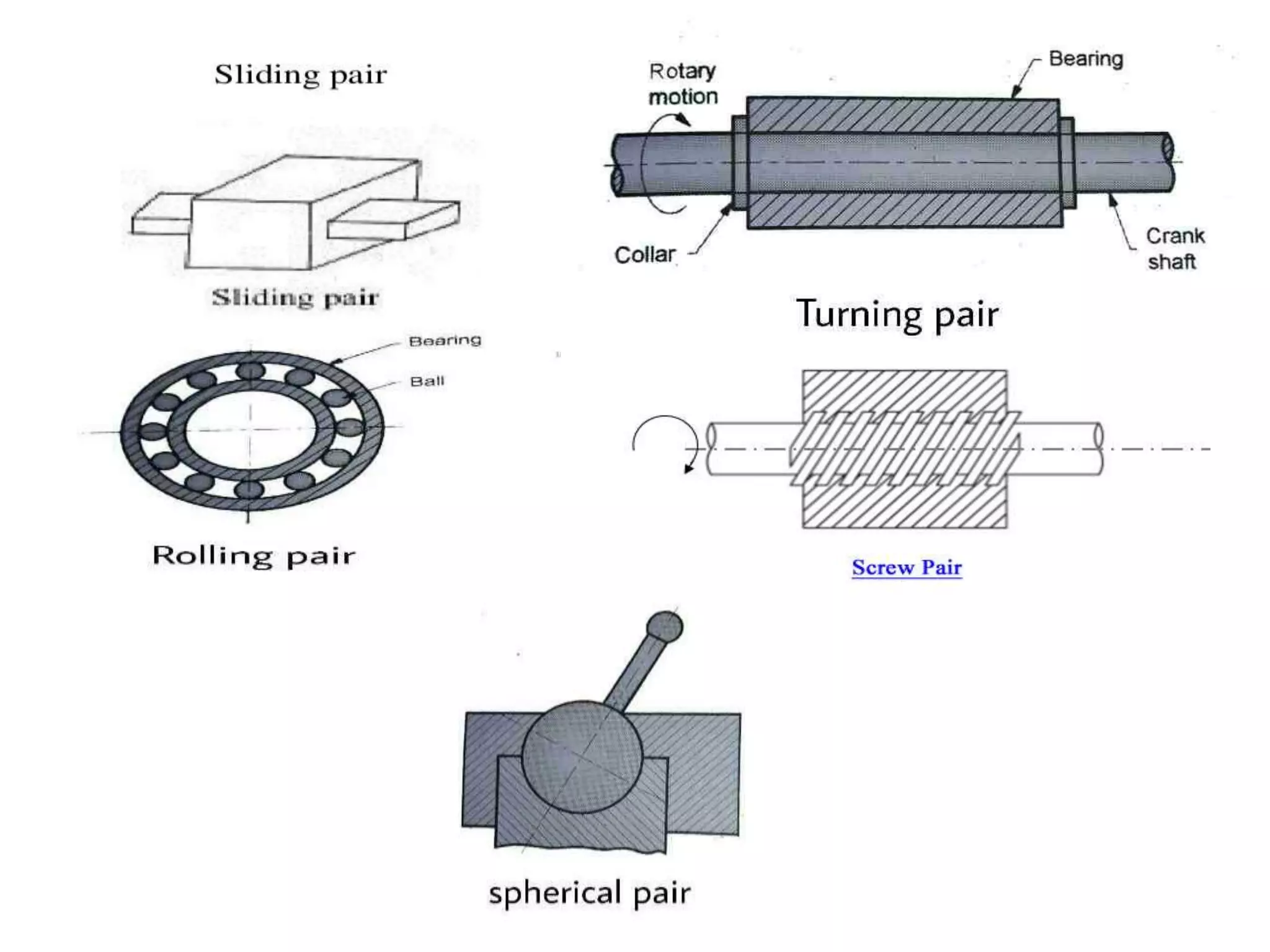

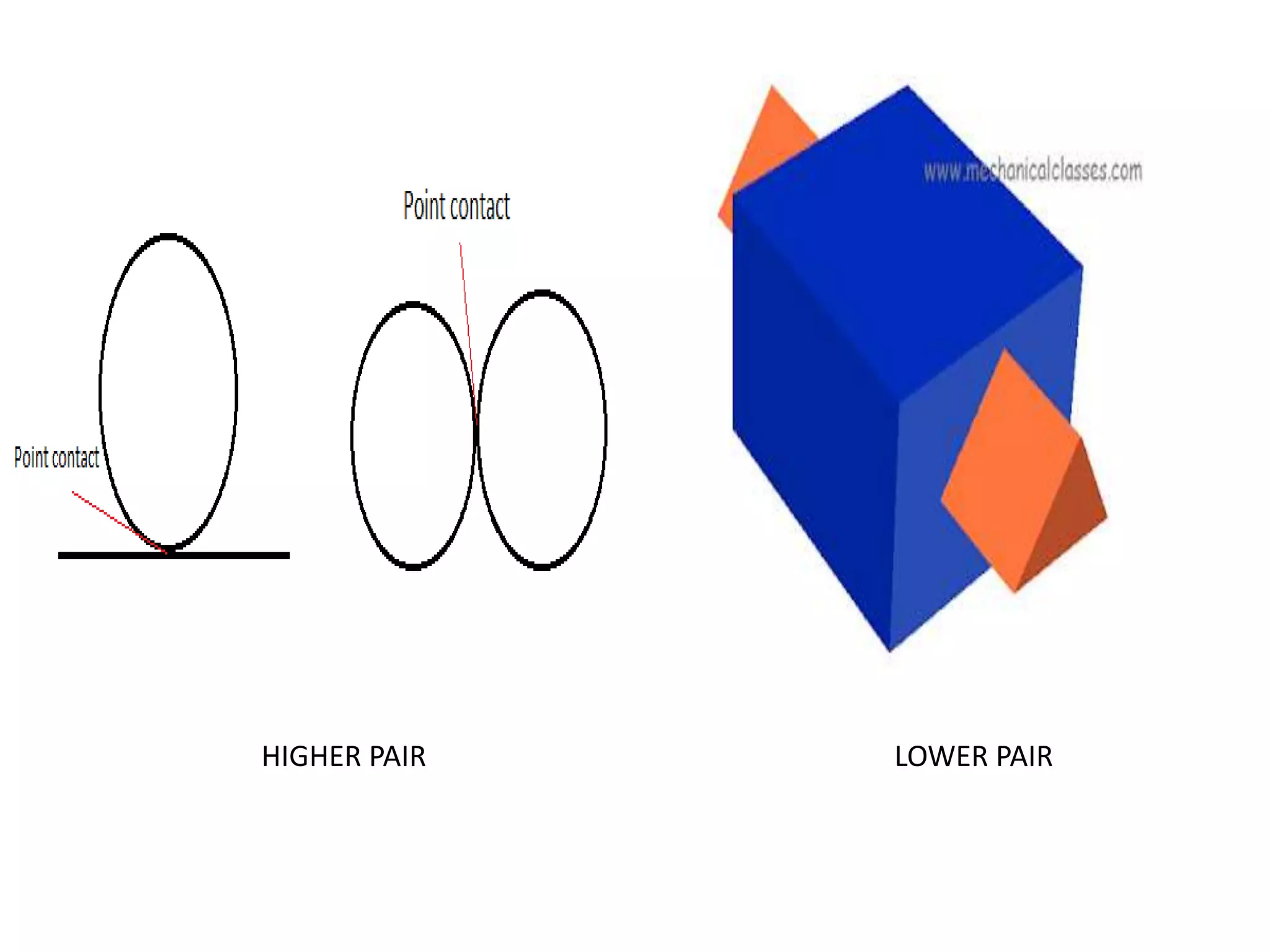

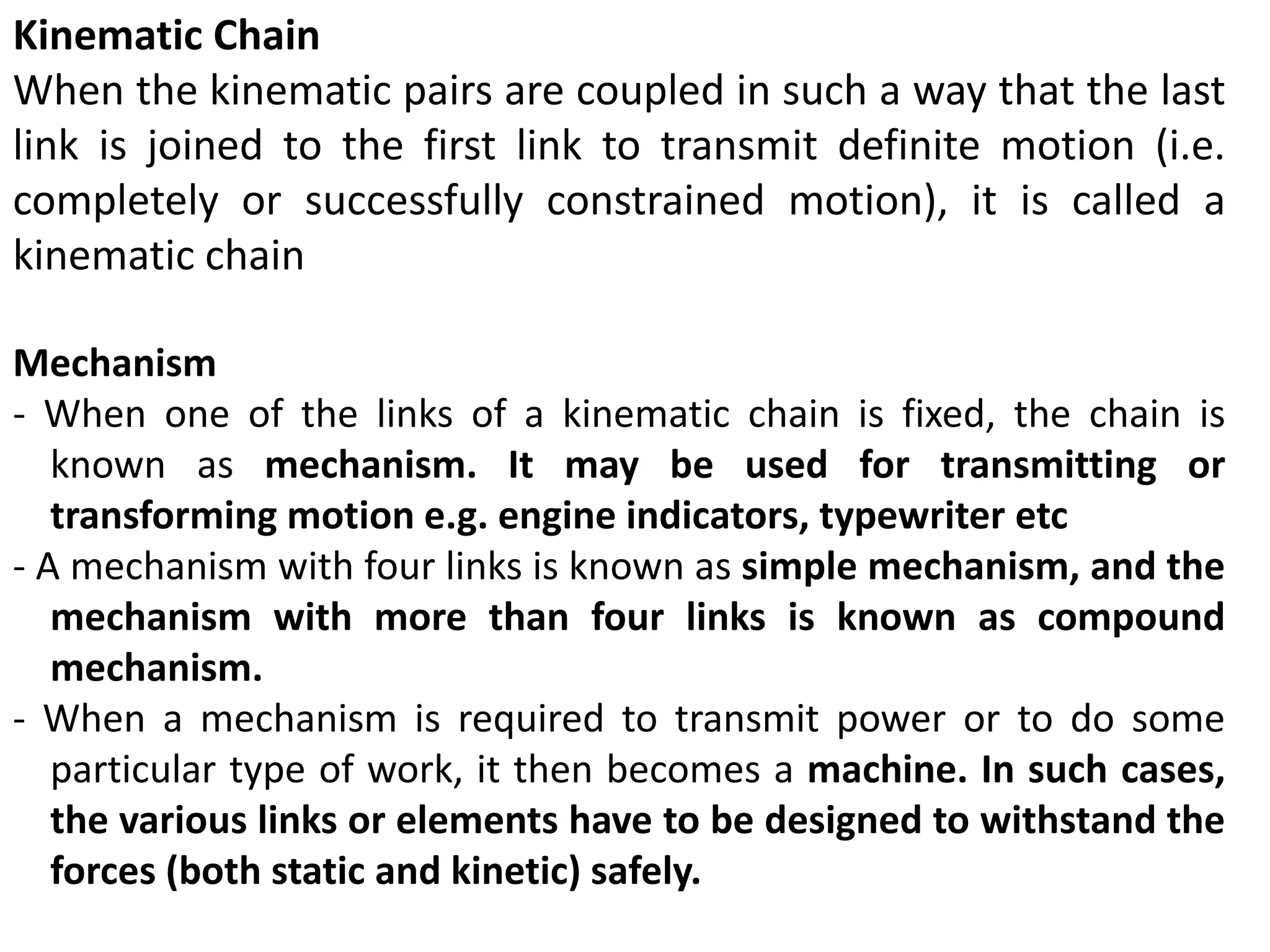

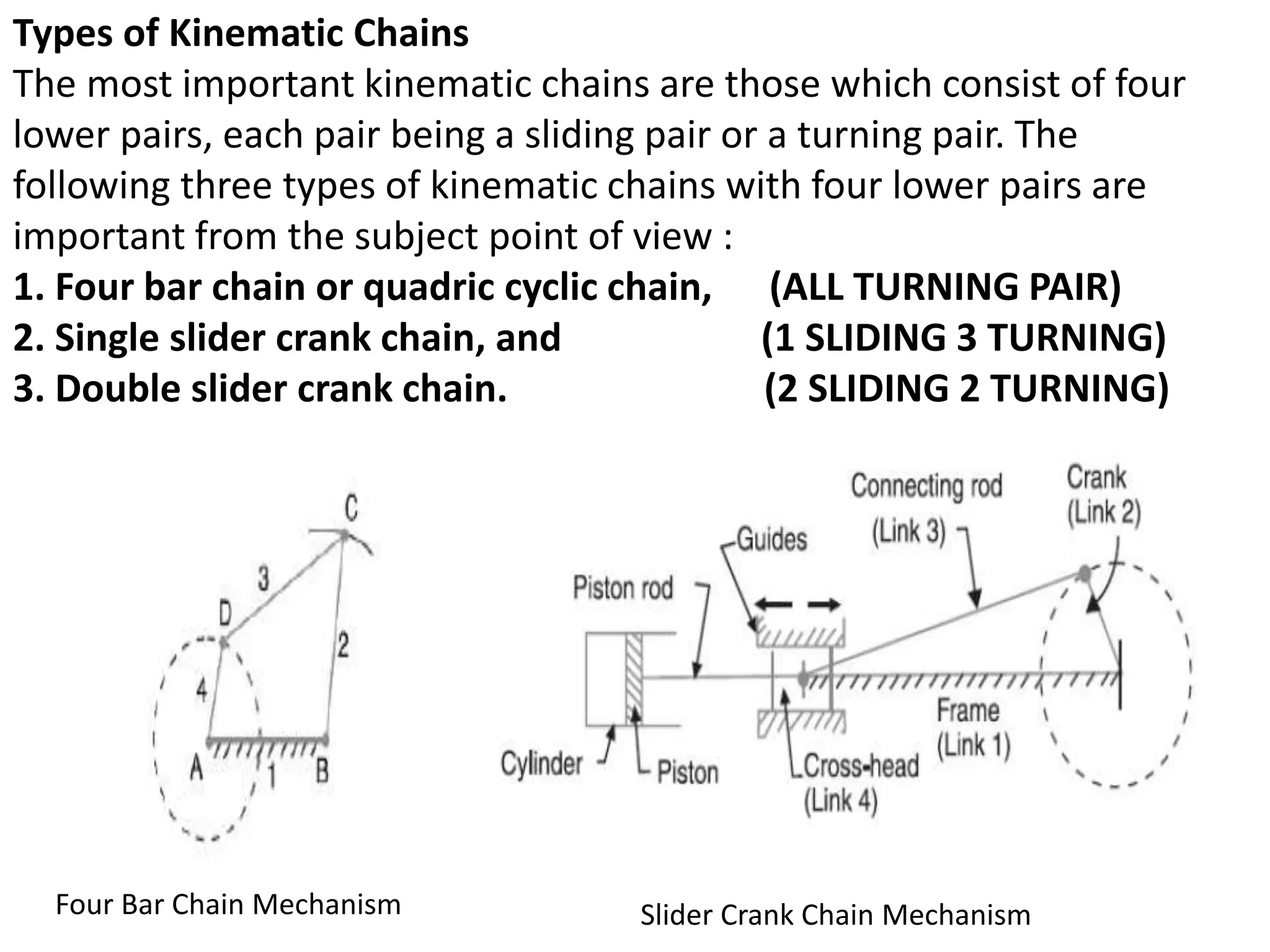

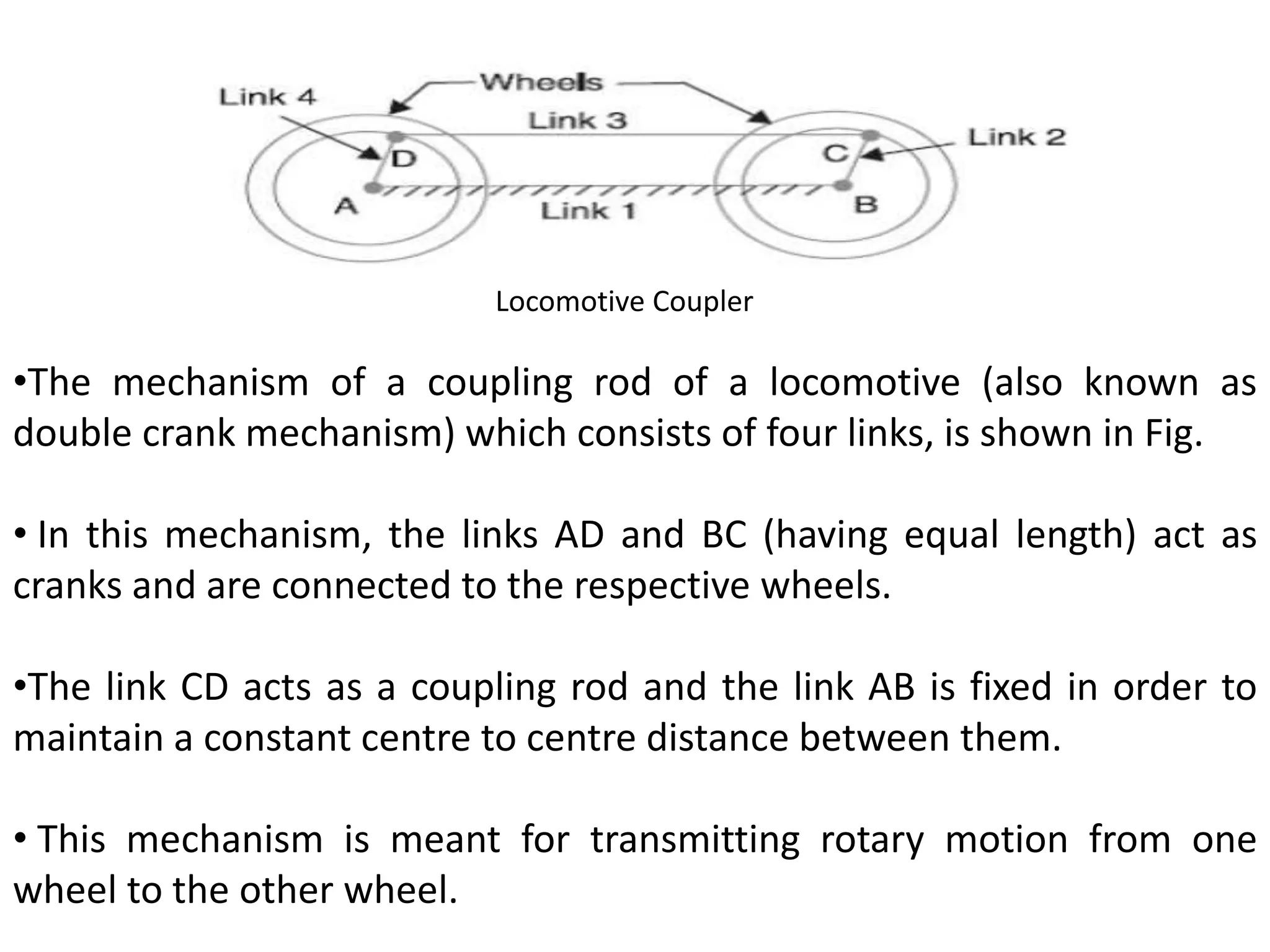

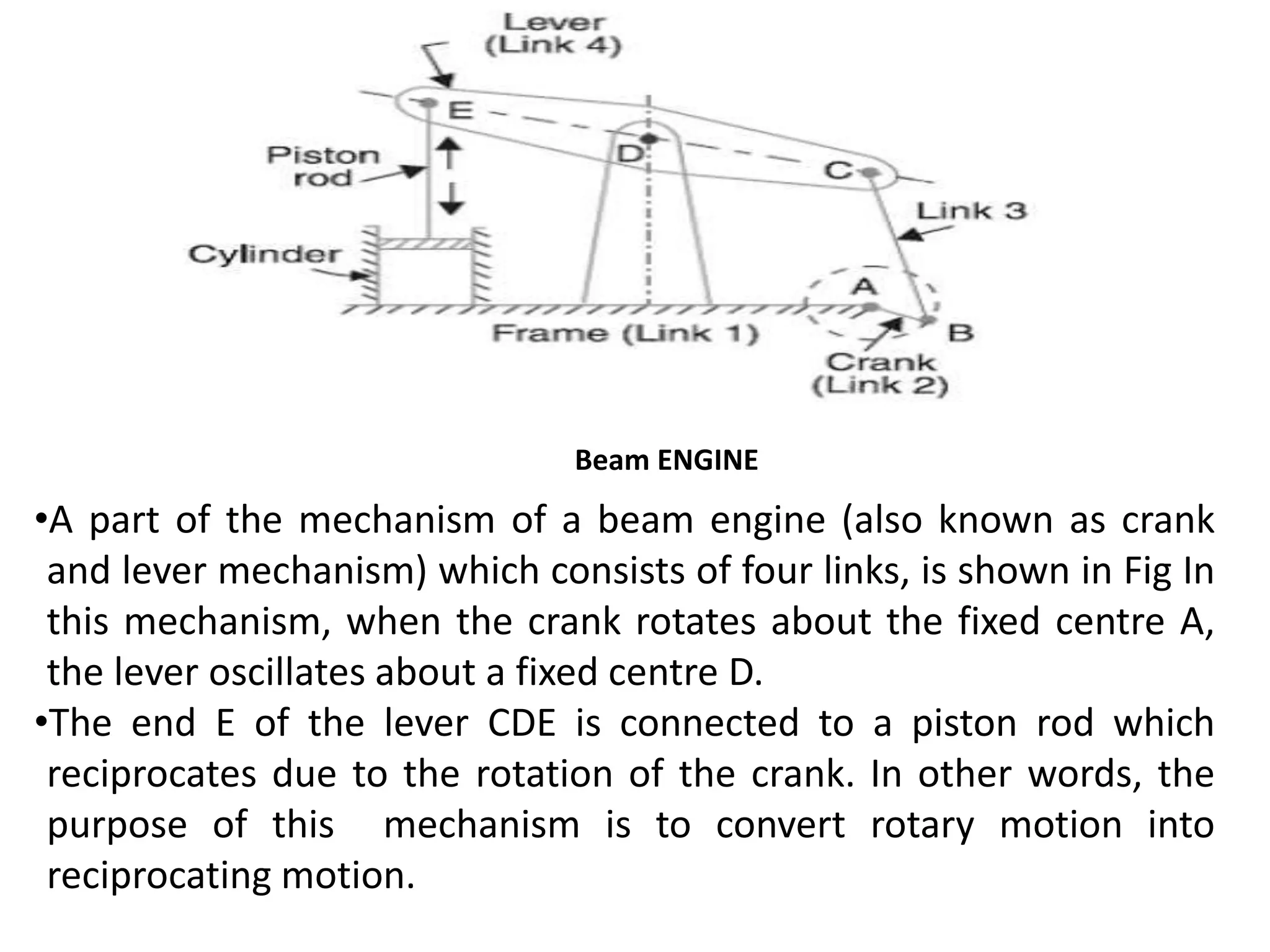

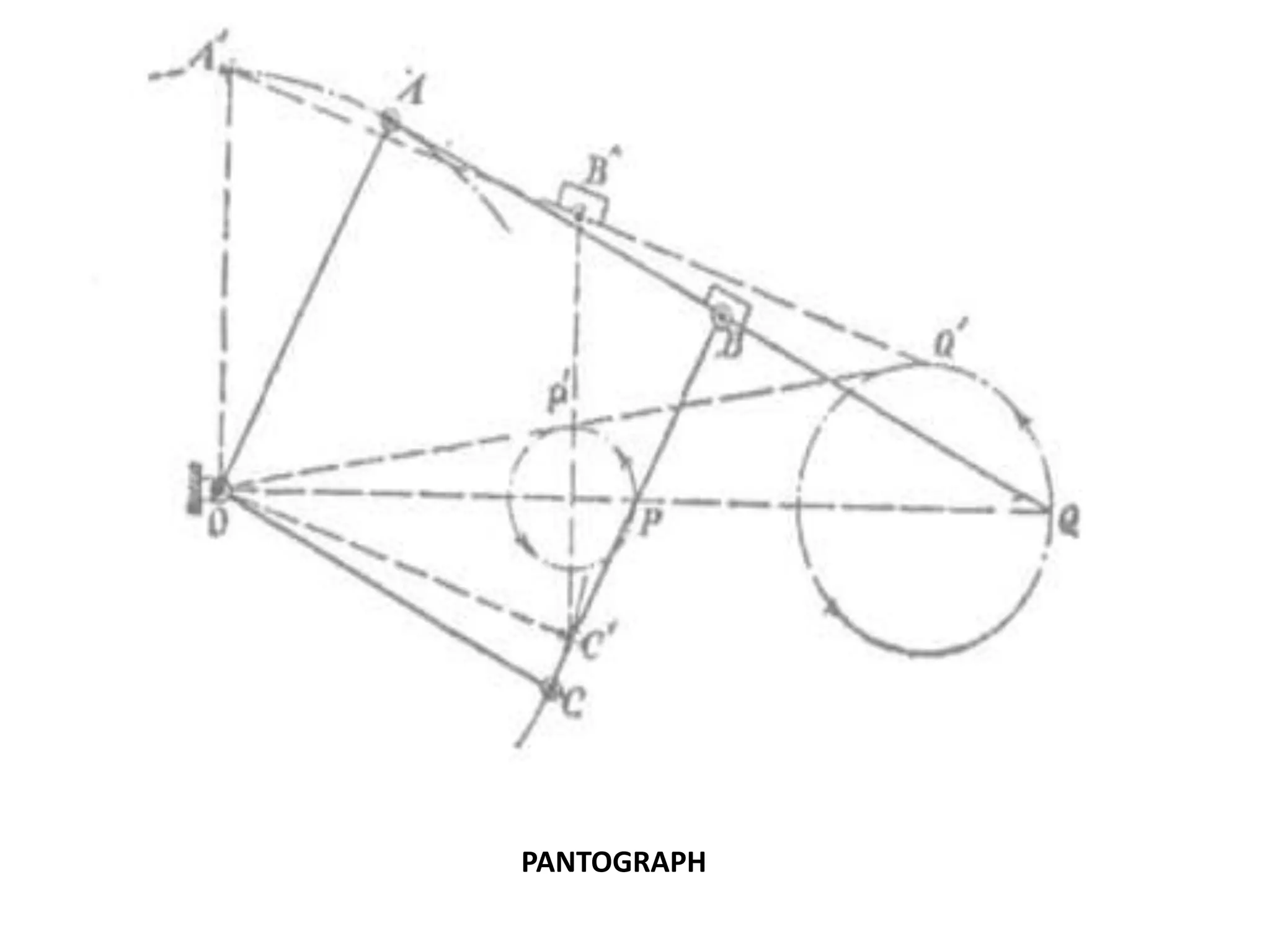

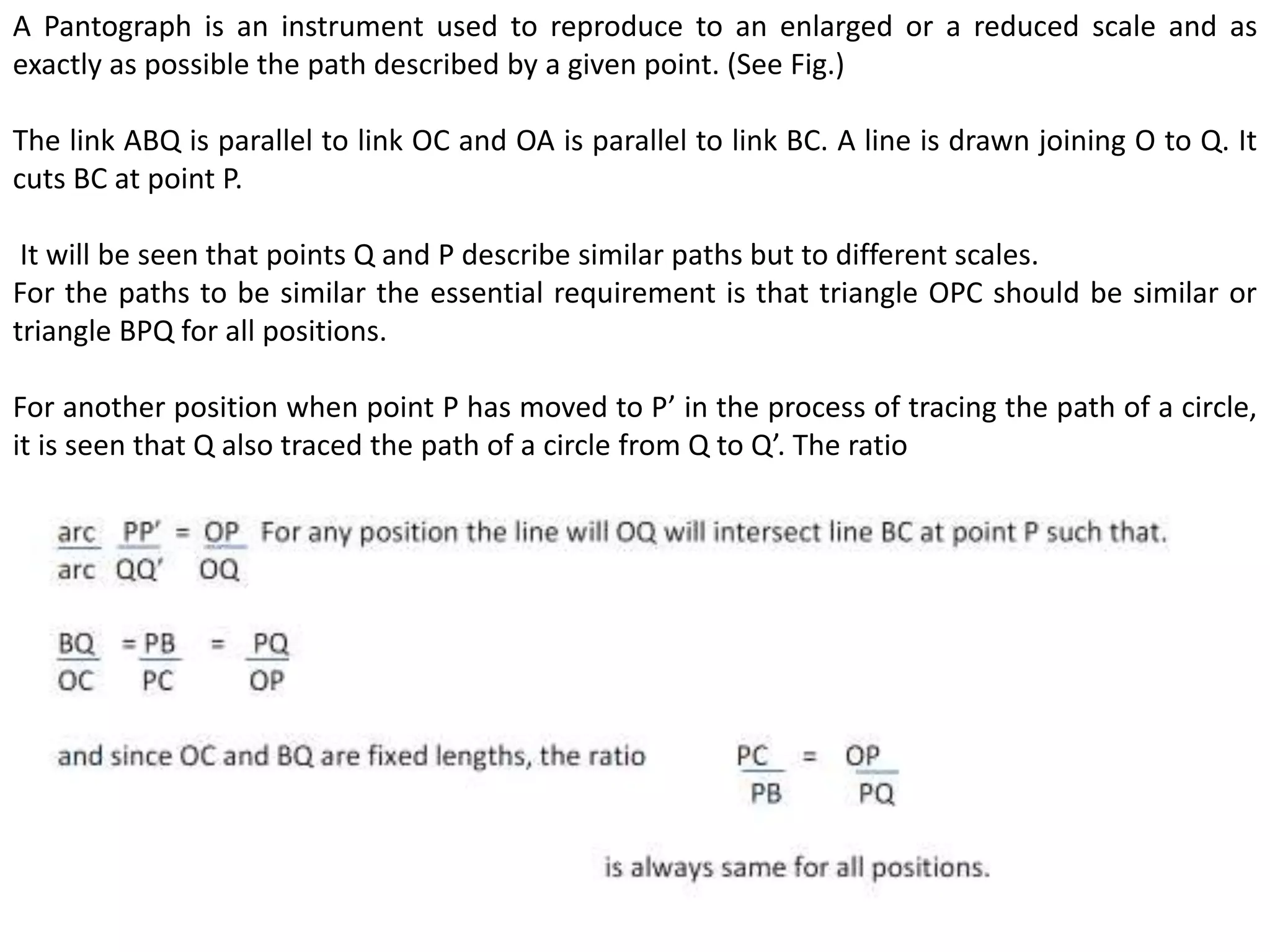

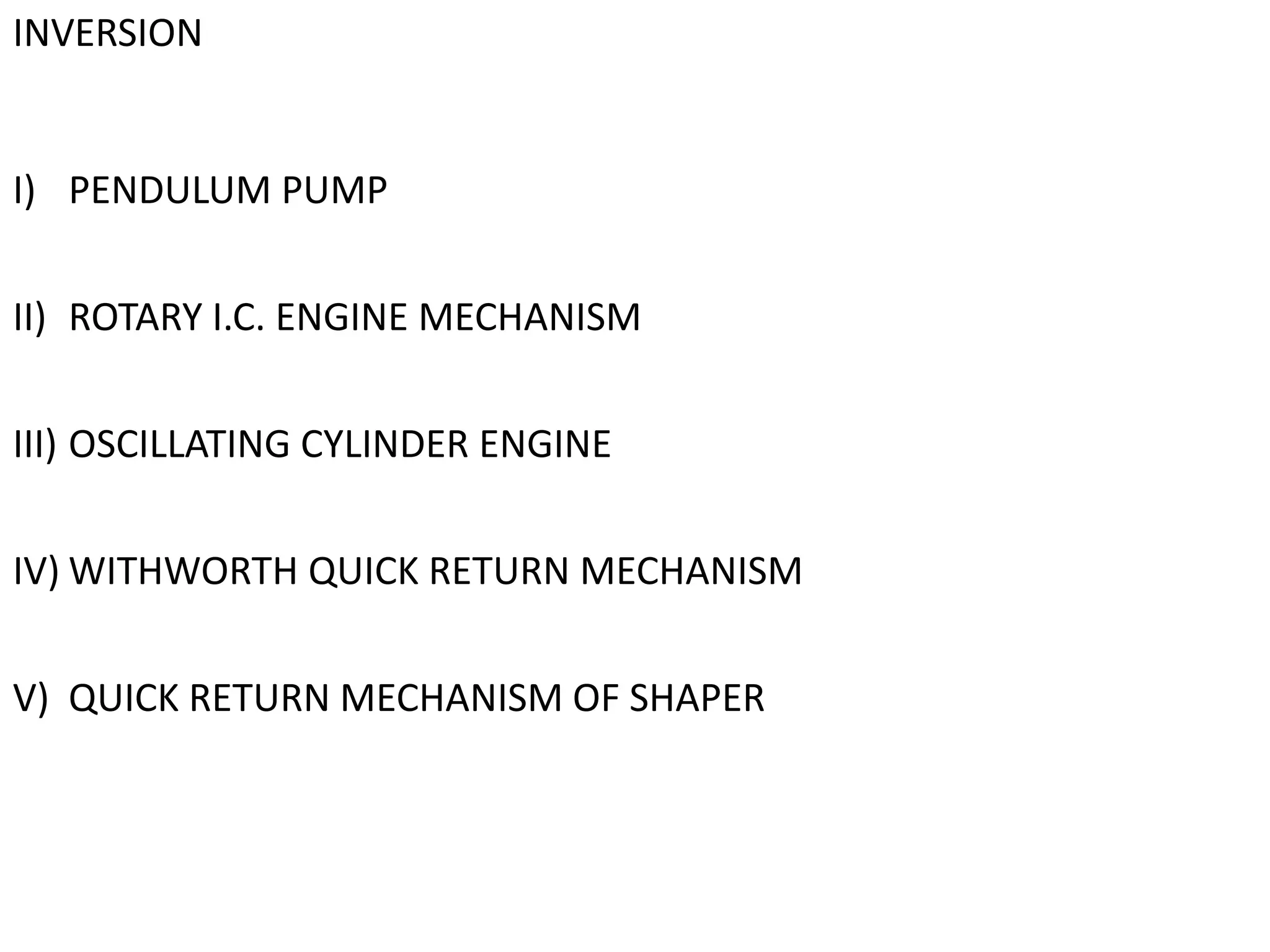

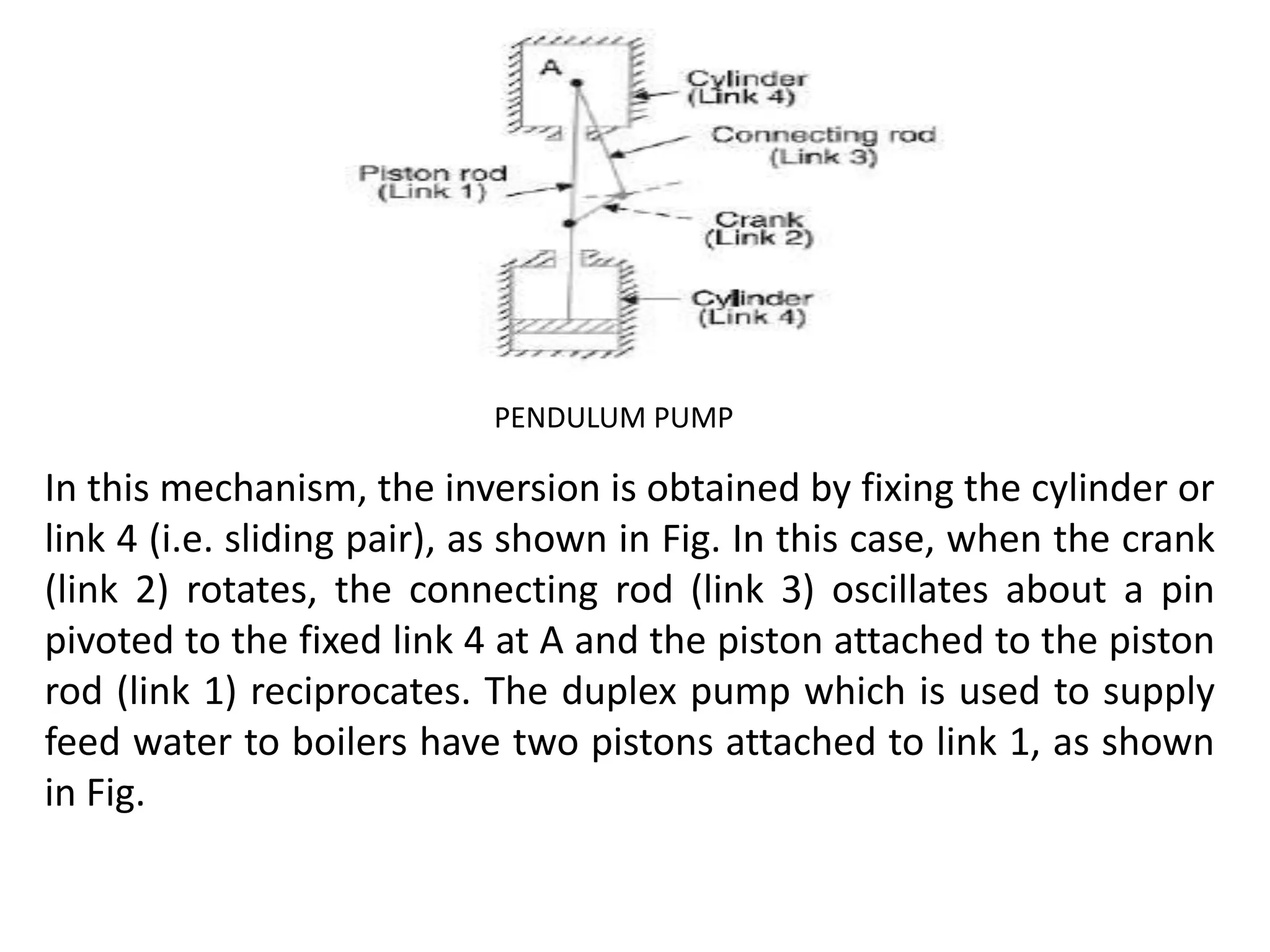

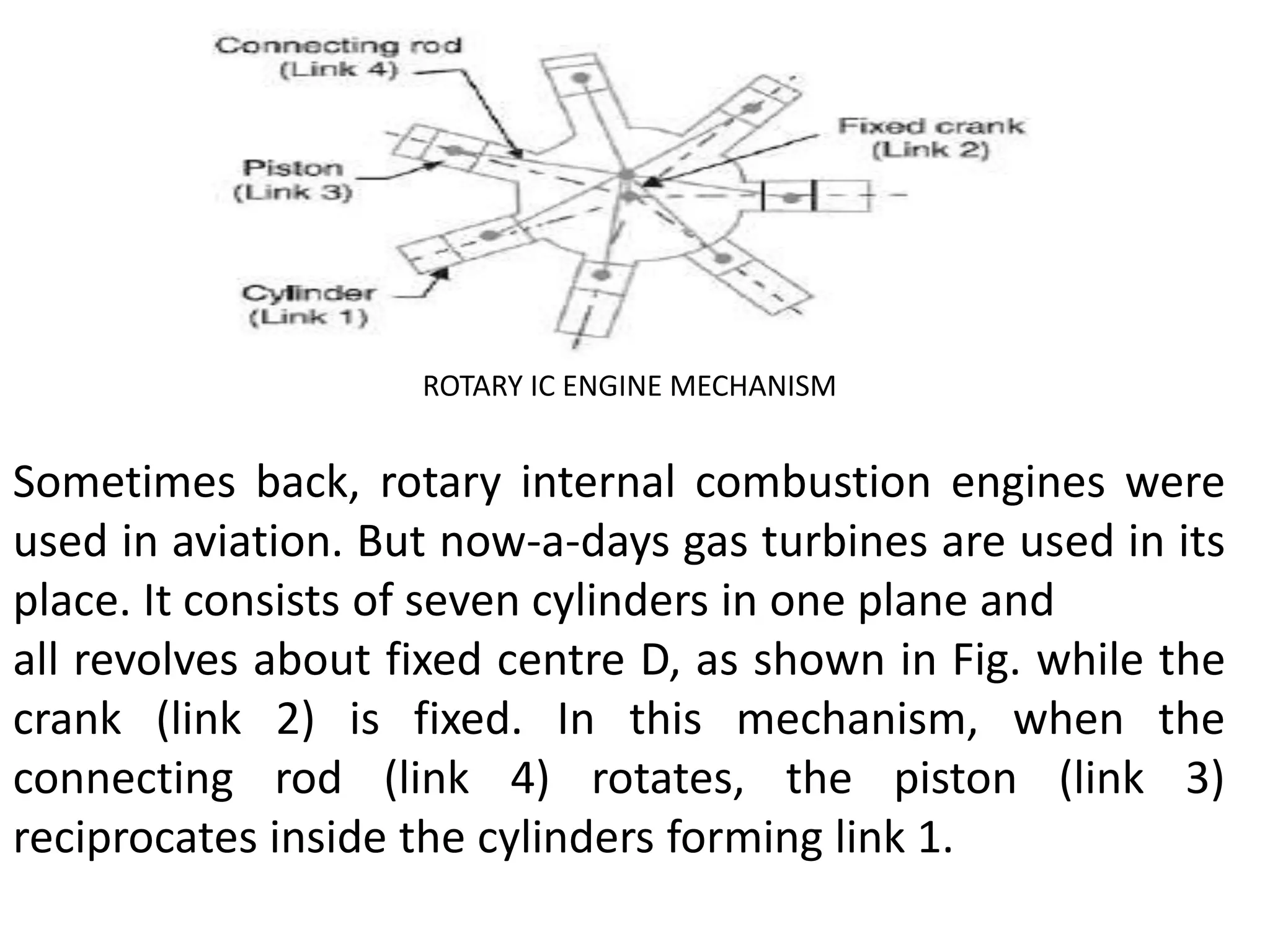

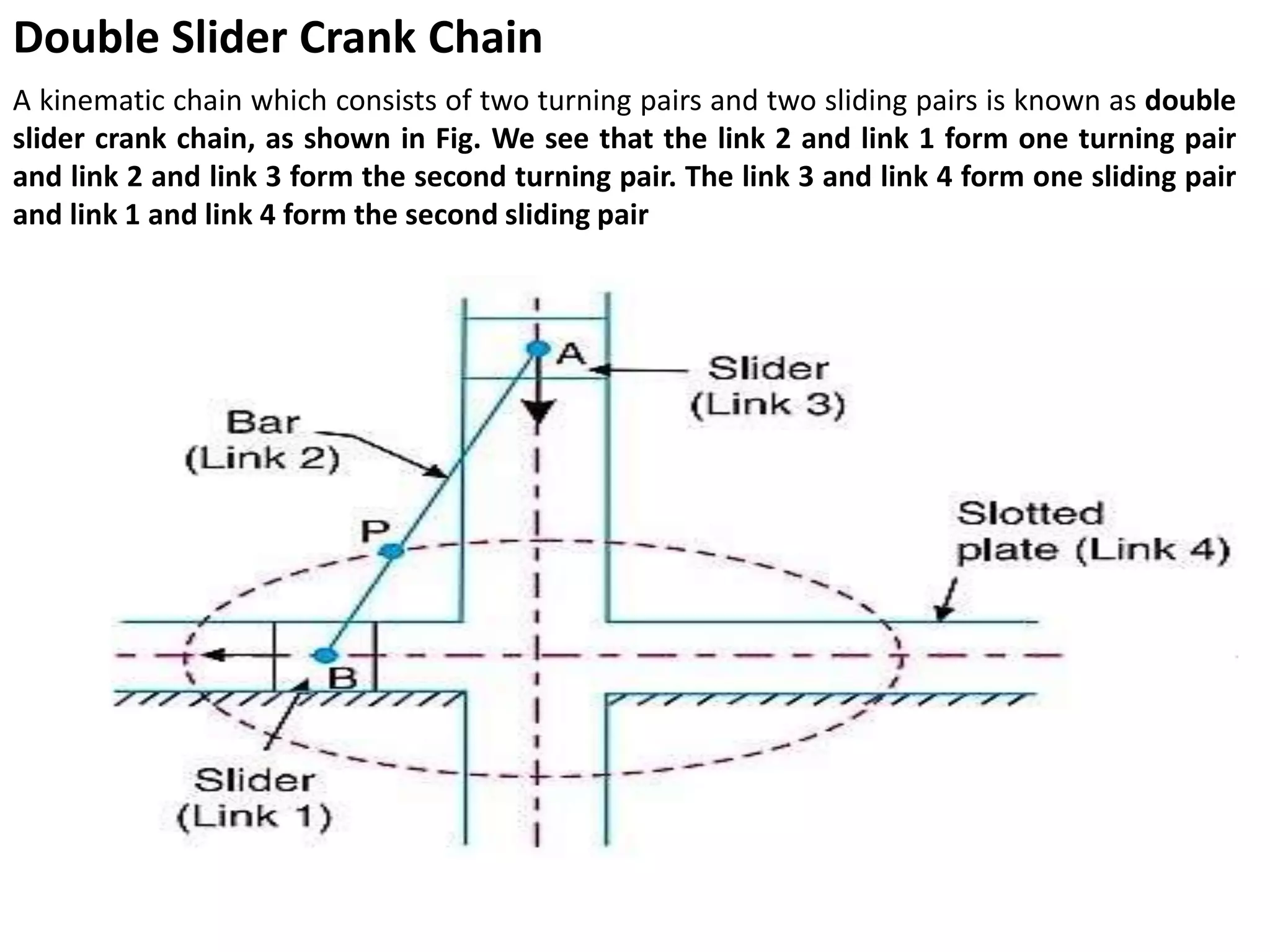

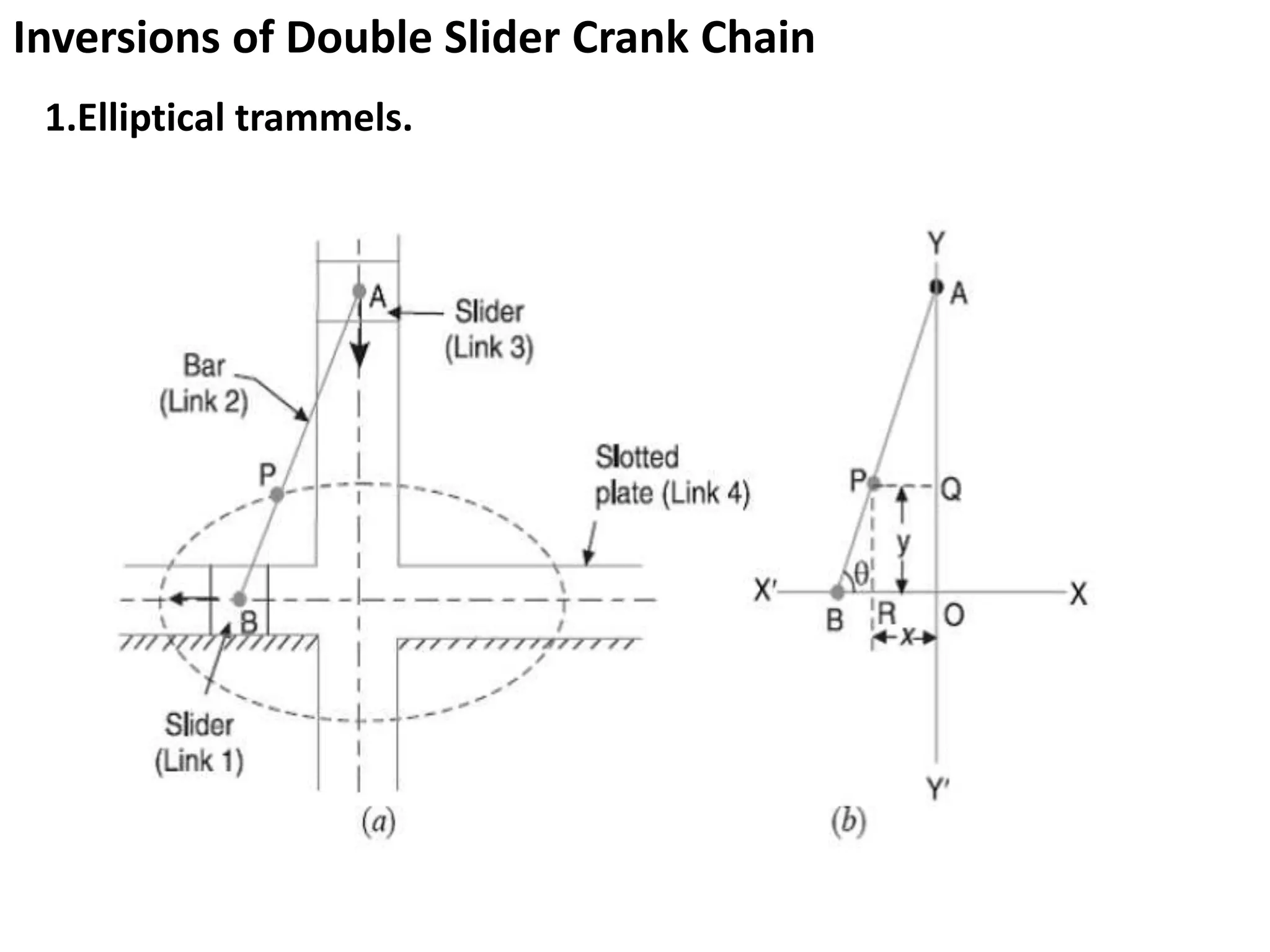

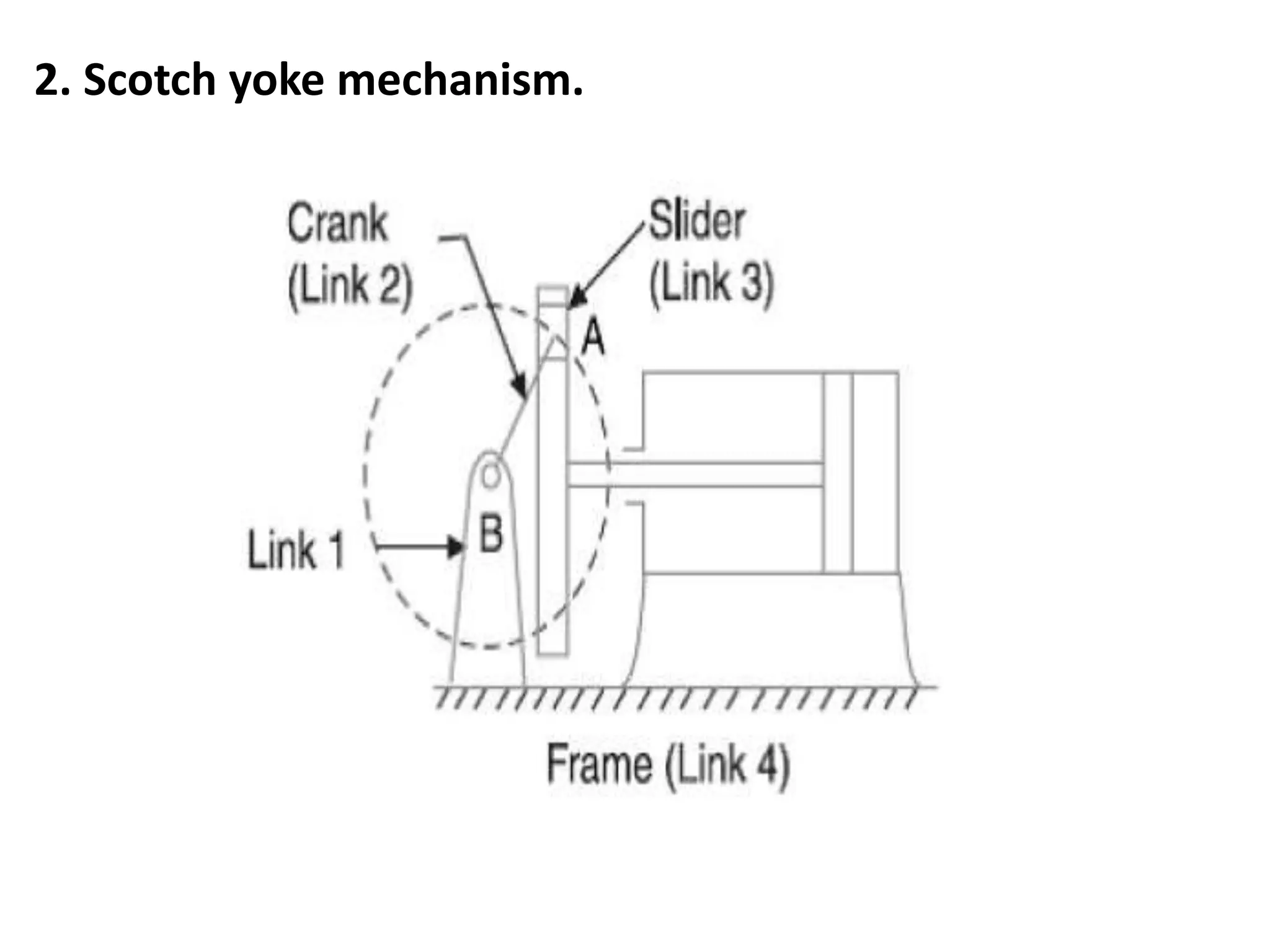

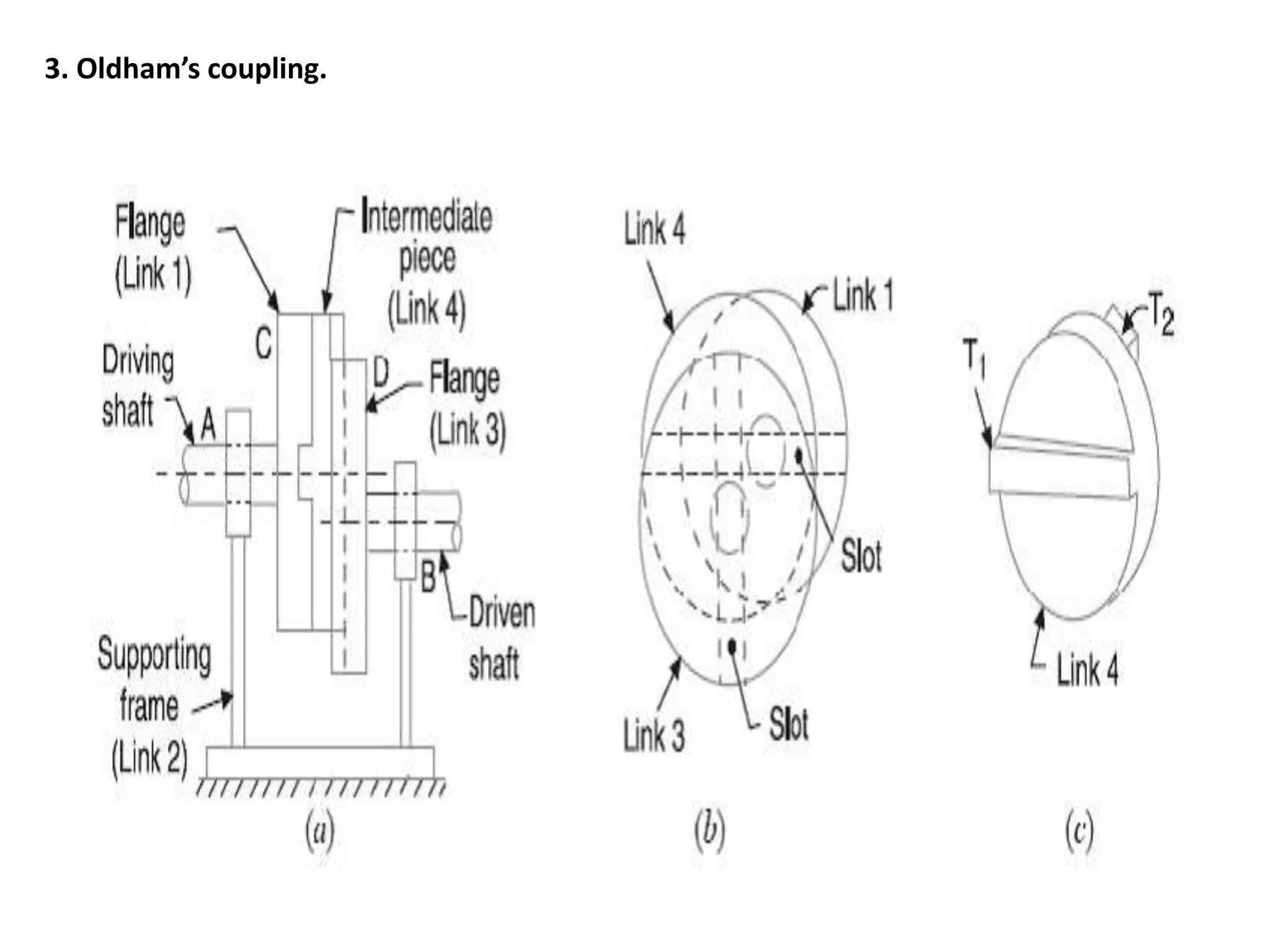

The document explores the fundamentals of the theory of machines, covering key concepts such as kinematics, dynamics, and types of links (rigid, flexible, fluid) in mechanisms. It explains the classification of kinematic pairs, constrained motions, and kinematic chains, highlighting various examples and types of mechanisms like four-bar chains and slider-crank mechanisms. Additionally, the document discusses the process of inversion in kinematic chains and provides practical applications of mechanisms in engineering.