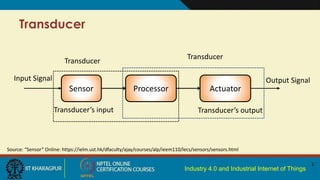

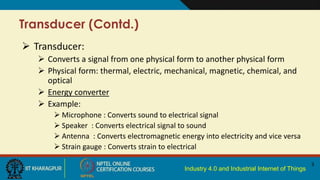

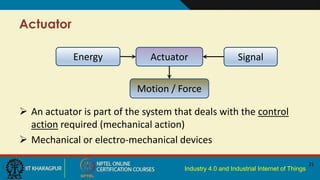

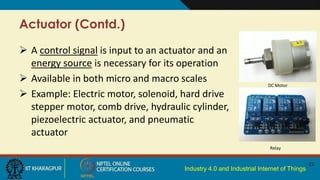

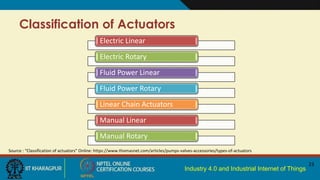

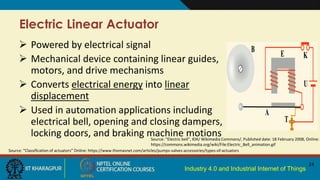

This document discusses sensors and actuators in Industry 4.0 and the Industrial Internet of Things. It defines sensors as devices that detect physical quantities and convert them into signals, and actuators as devices that convert energy signals into motion or force. It classifies sensors as passive or active, analog or digital, and scalar or vector. It also describes common sensor characteristics and classifications of actuators such as electric, fluid power, and manual linear and rotary actuators.