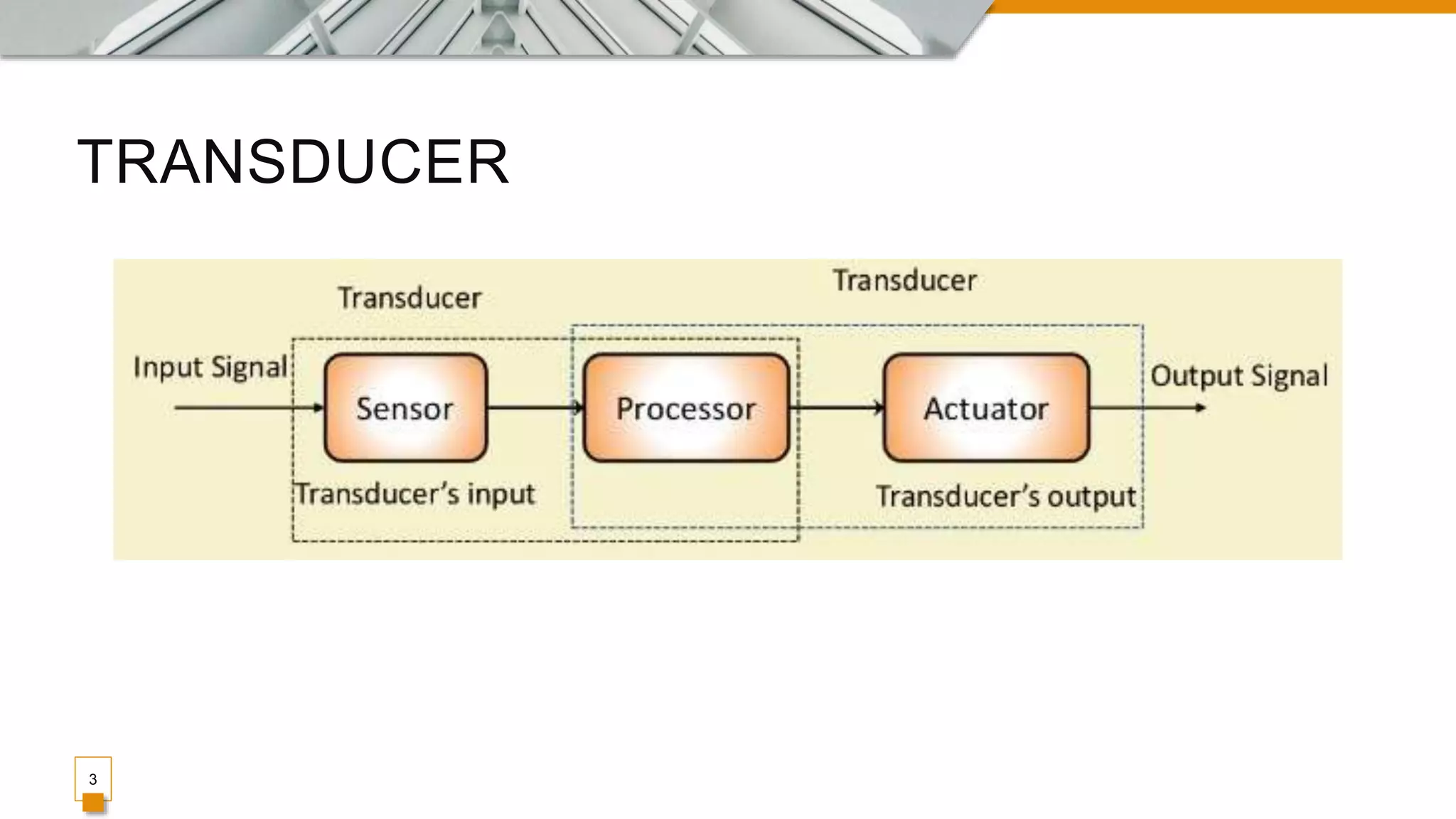

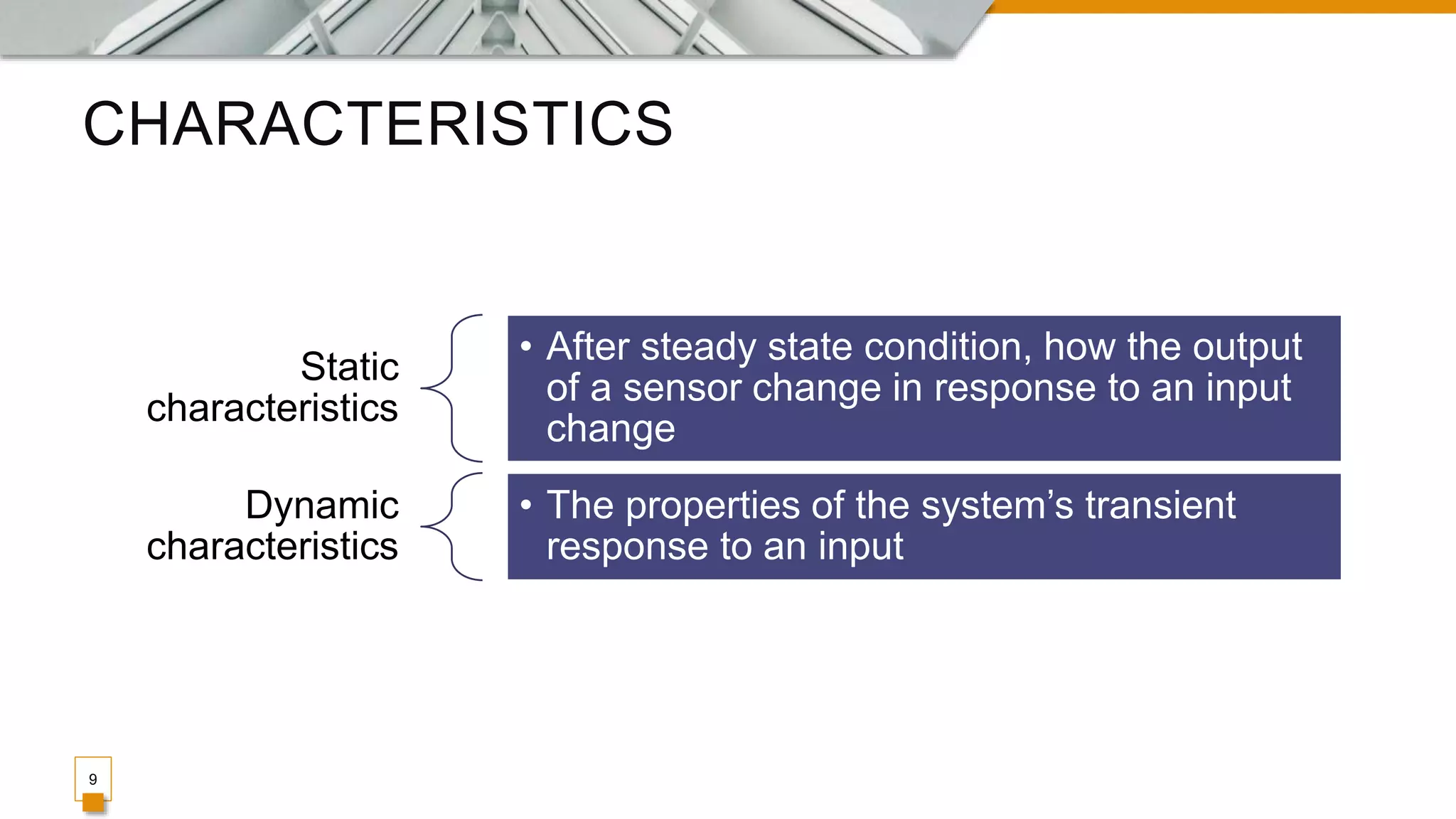

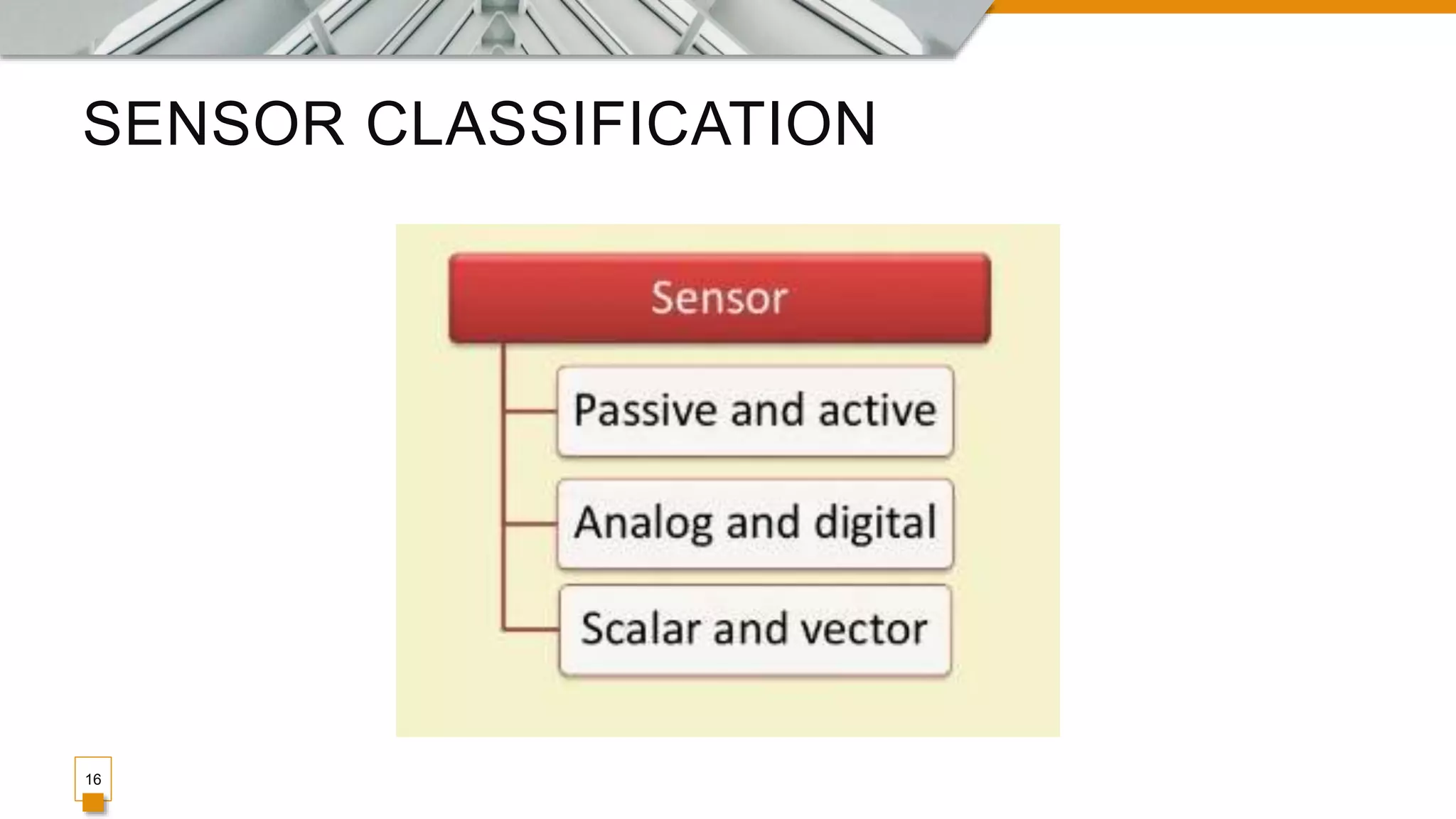

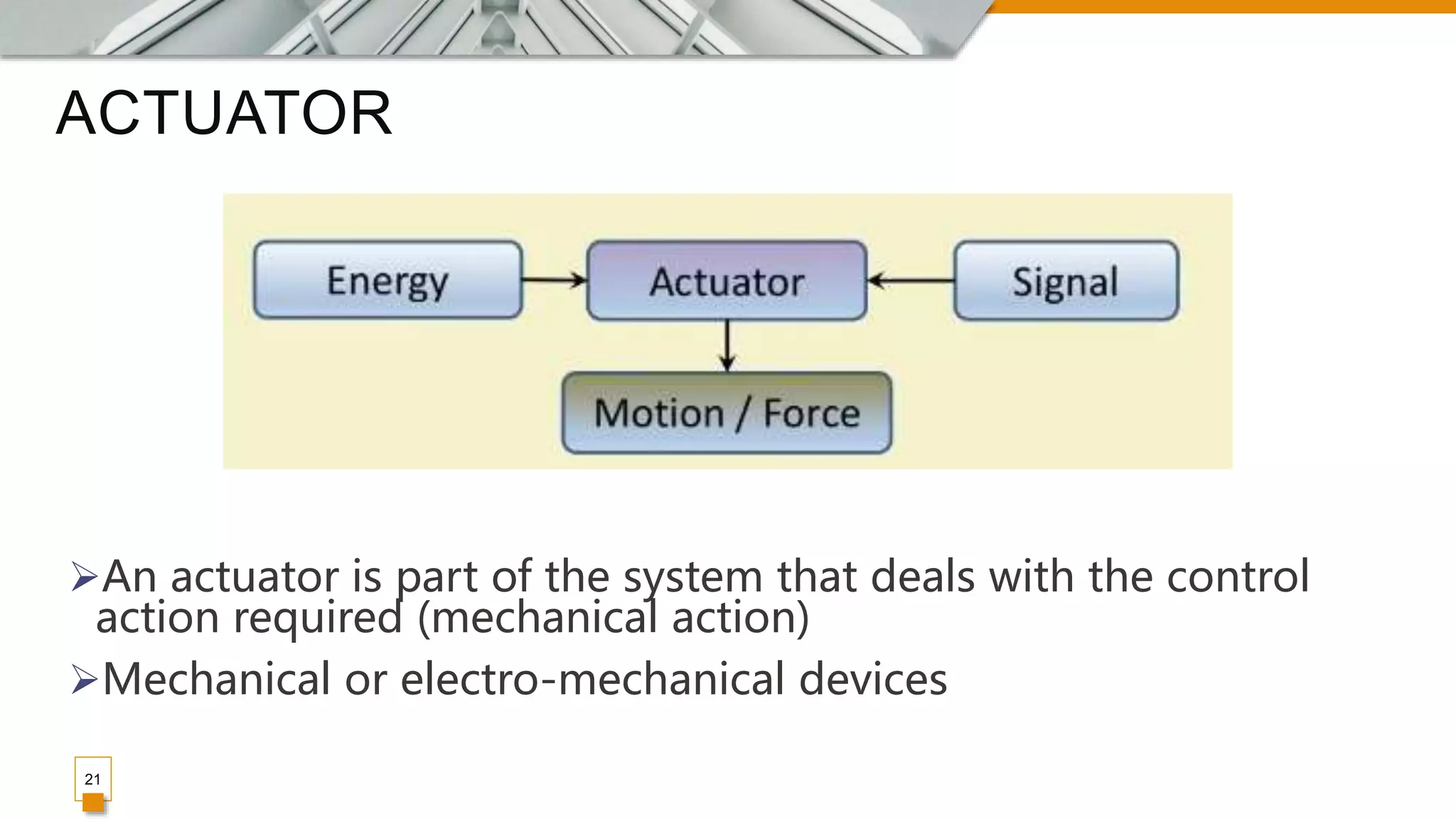

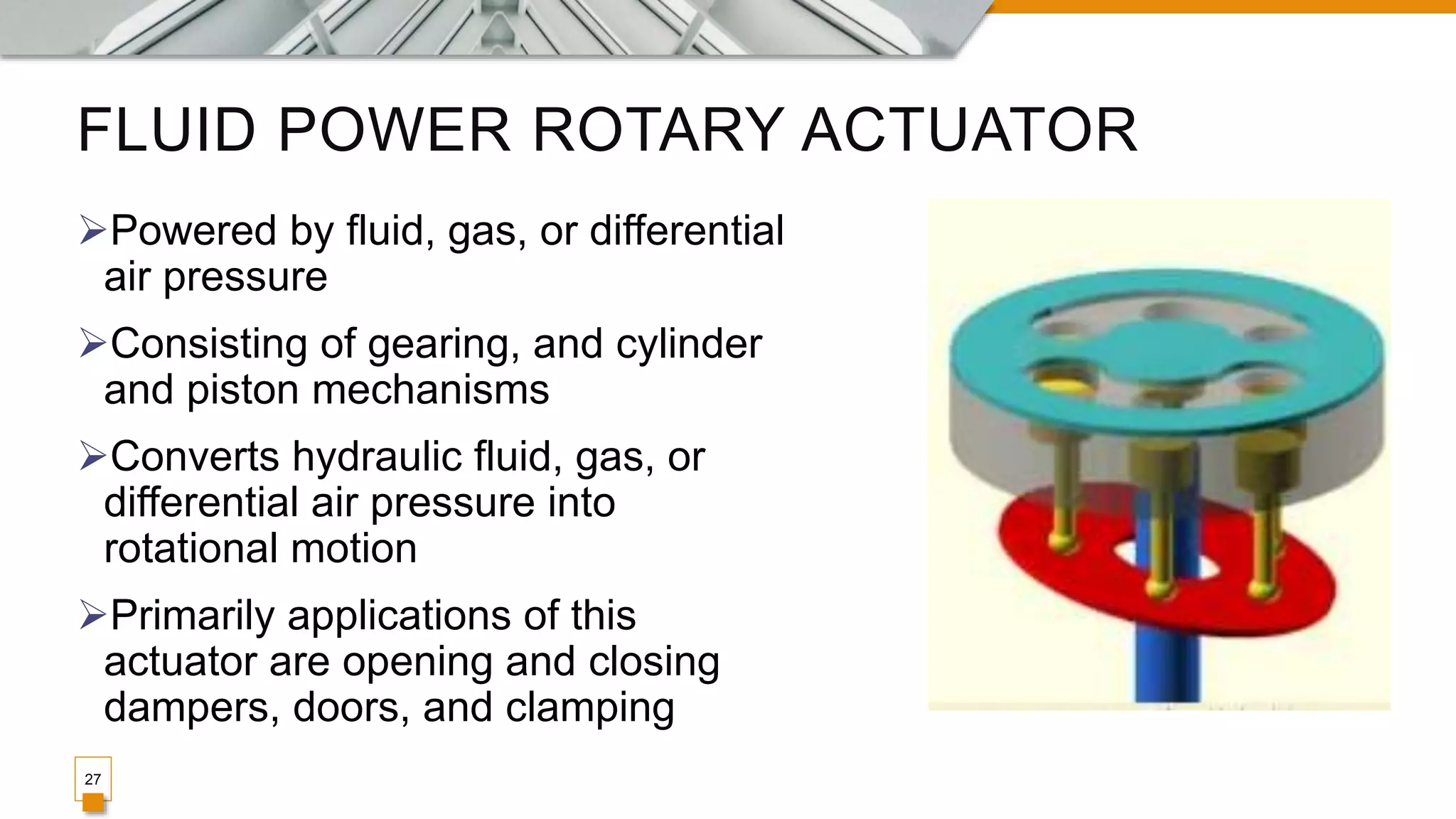

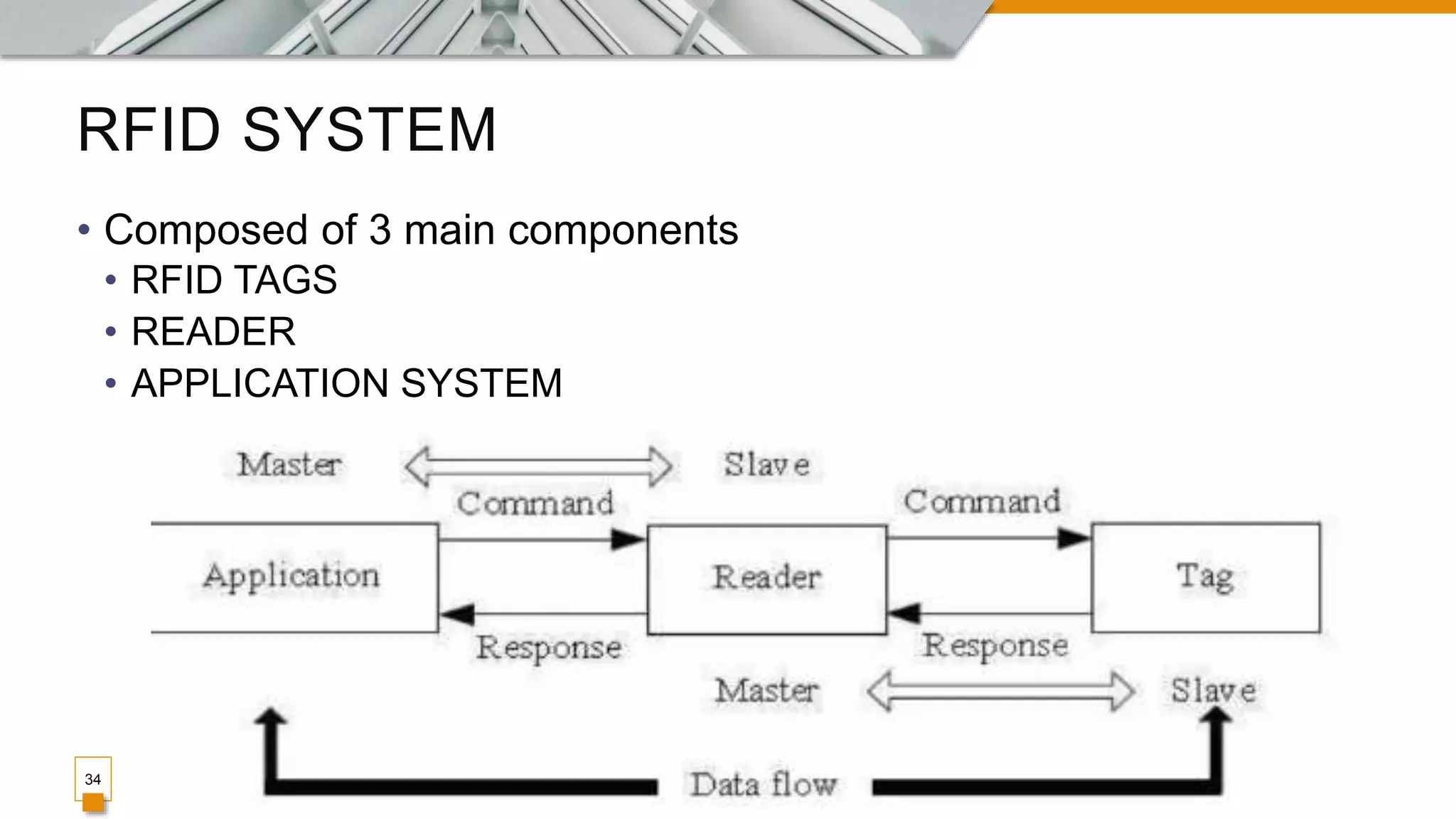

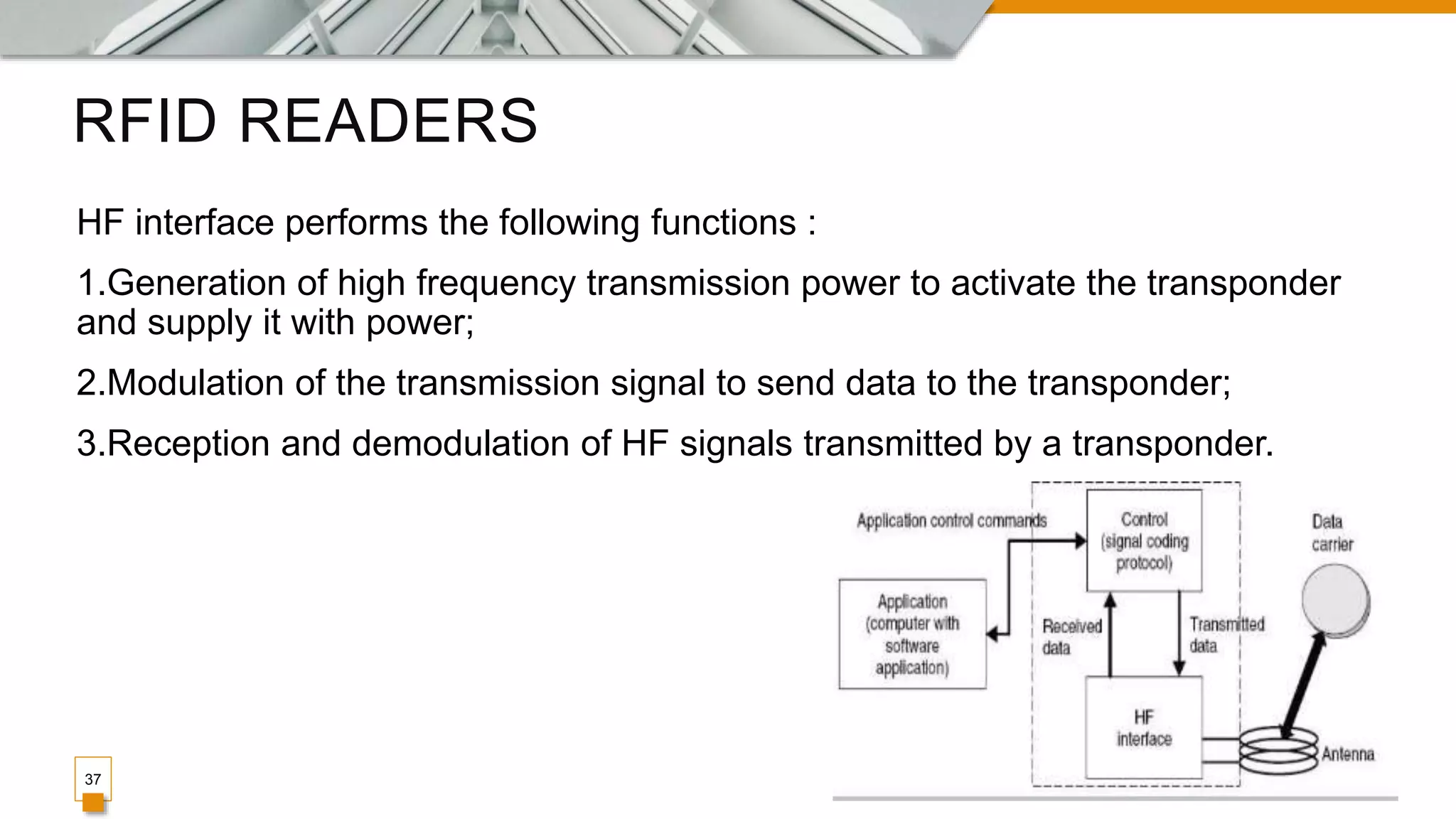

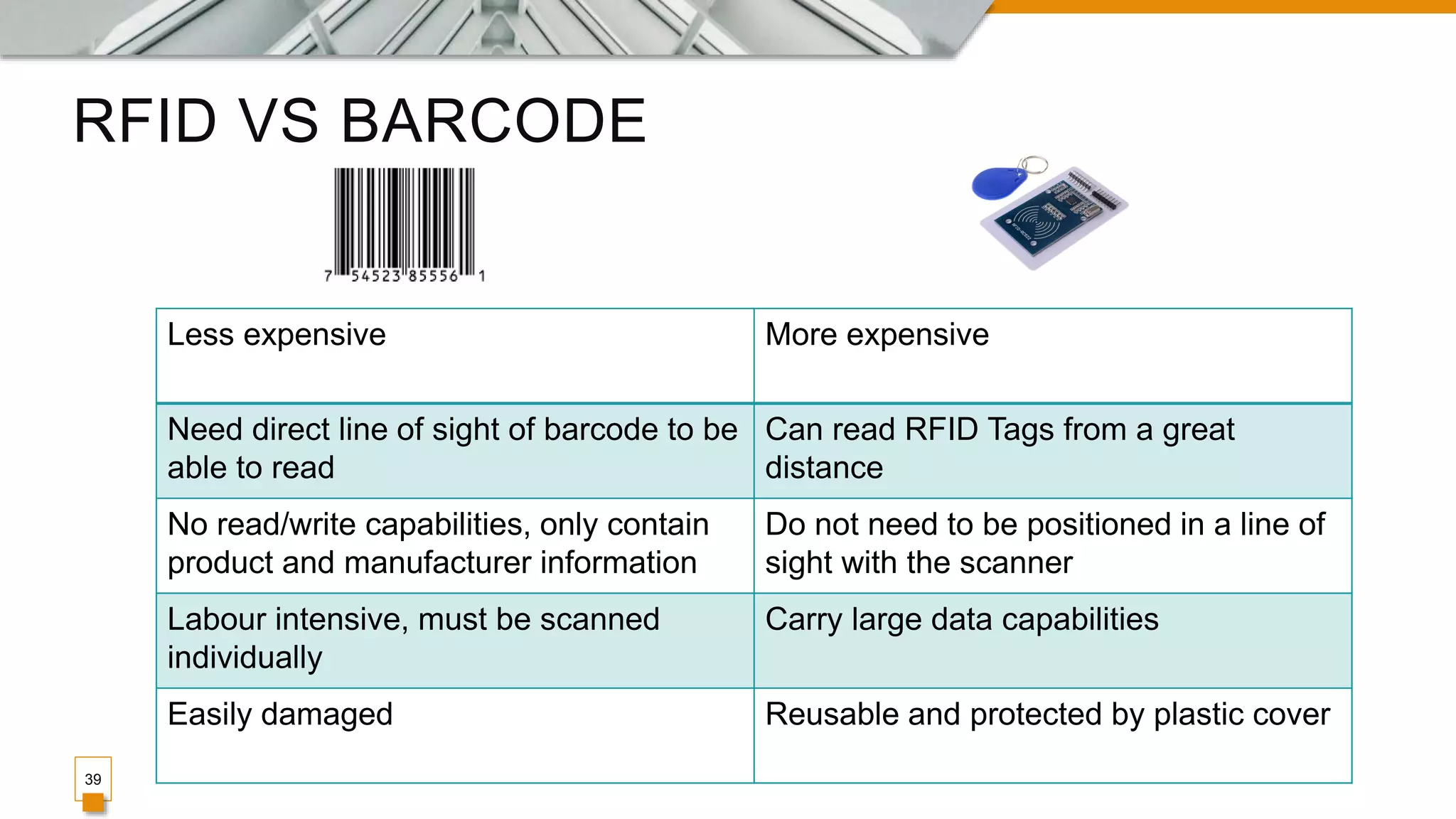

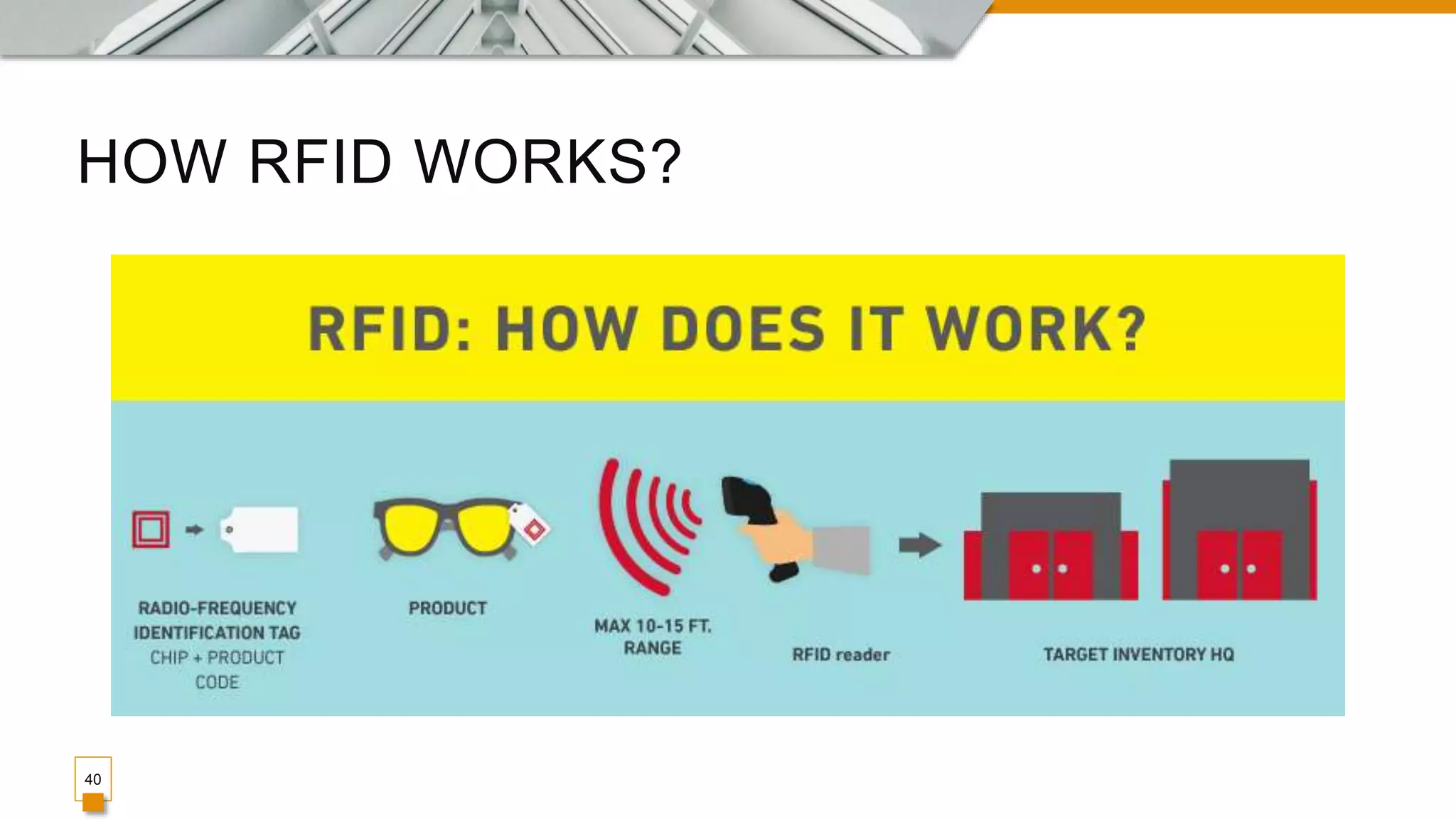

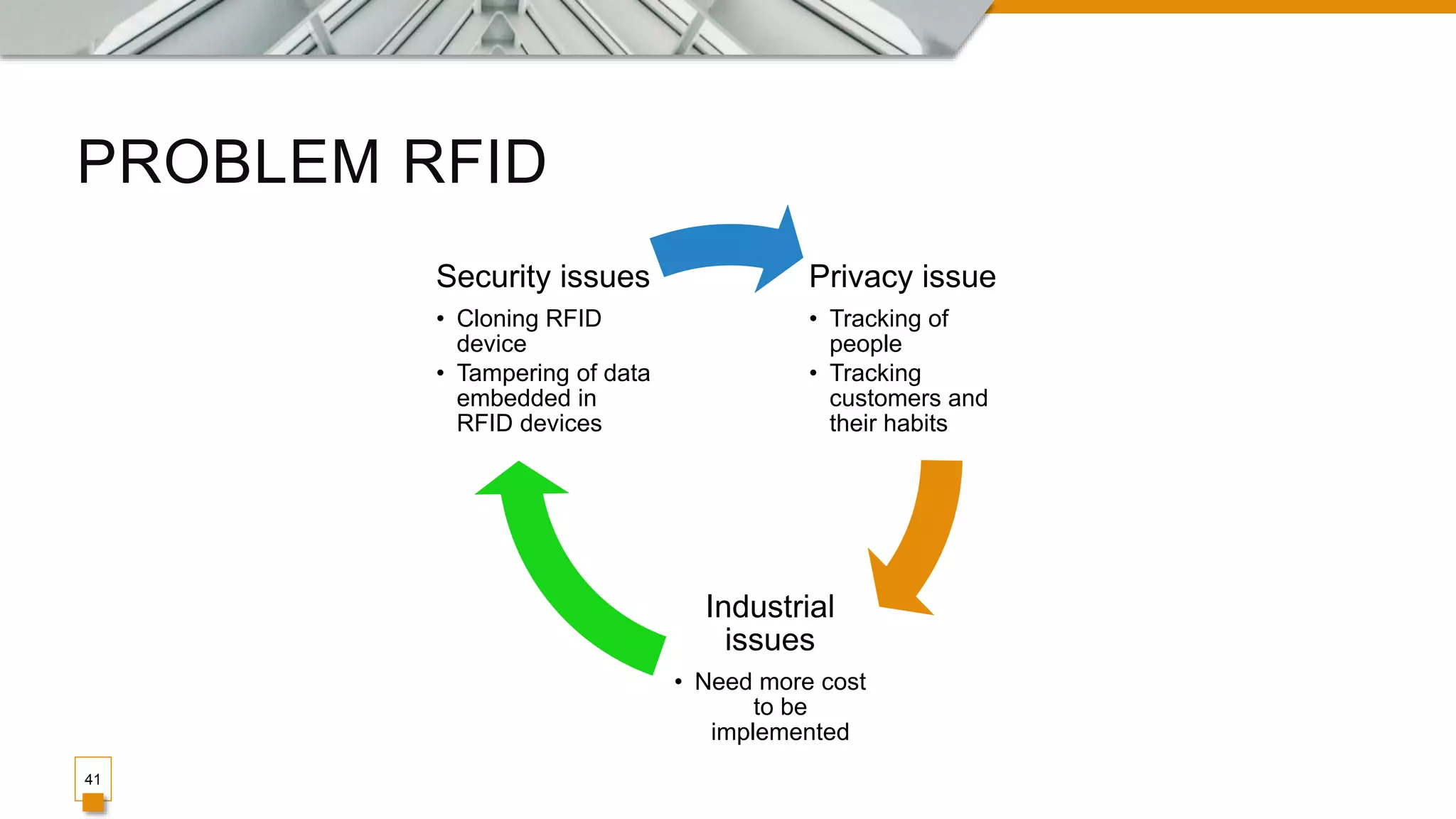

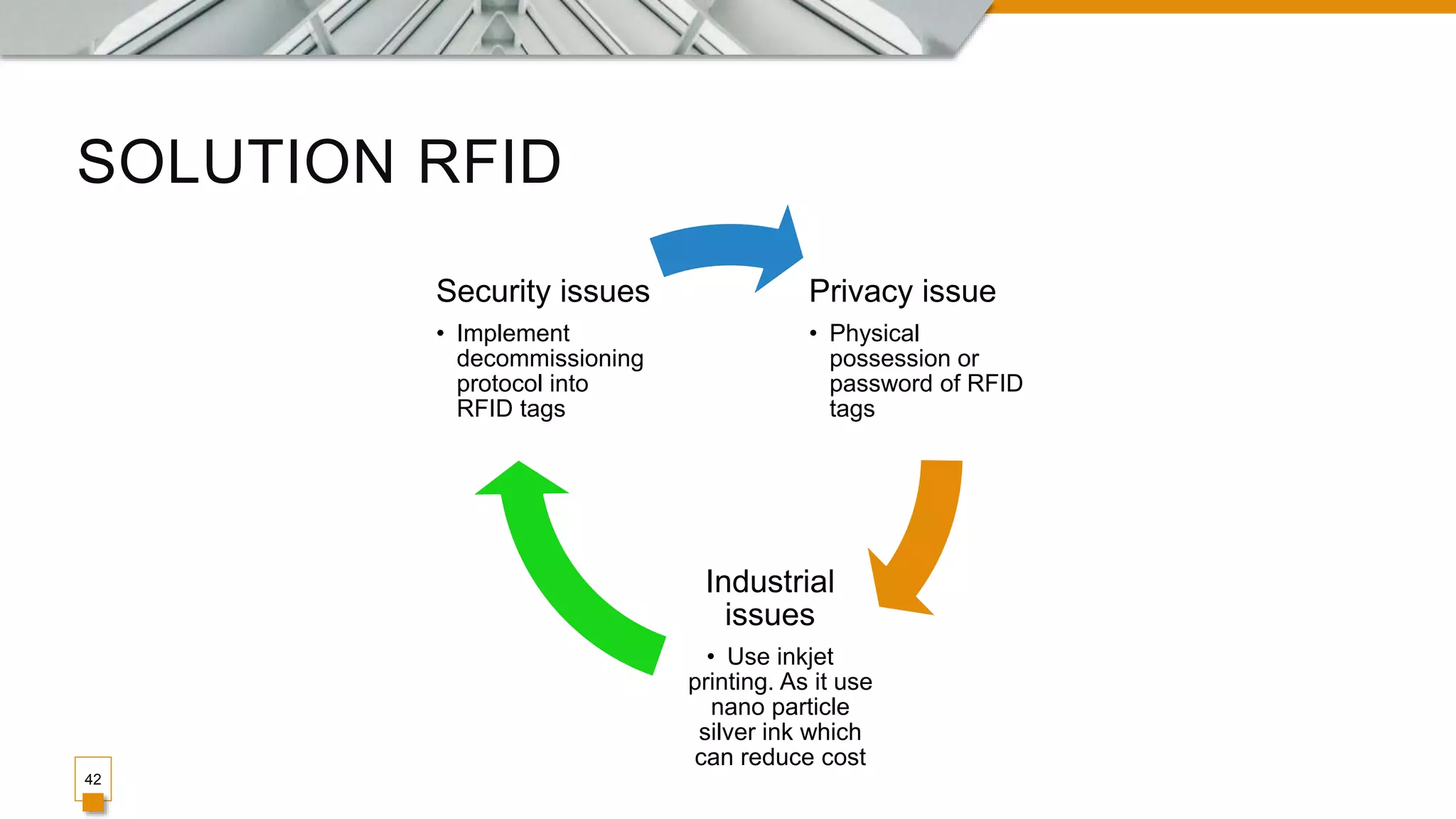

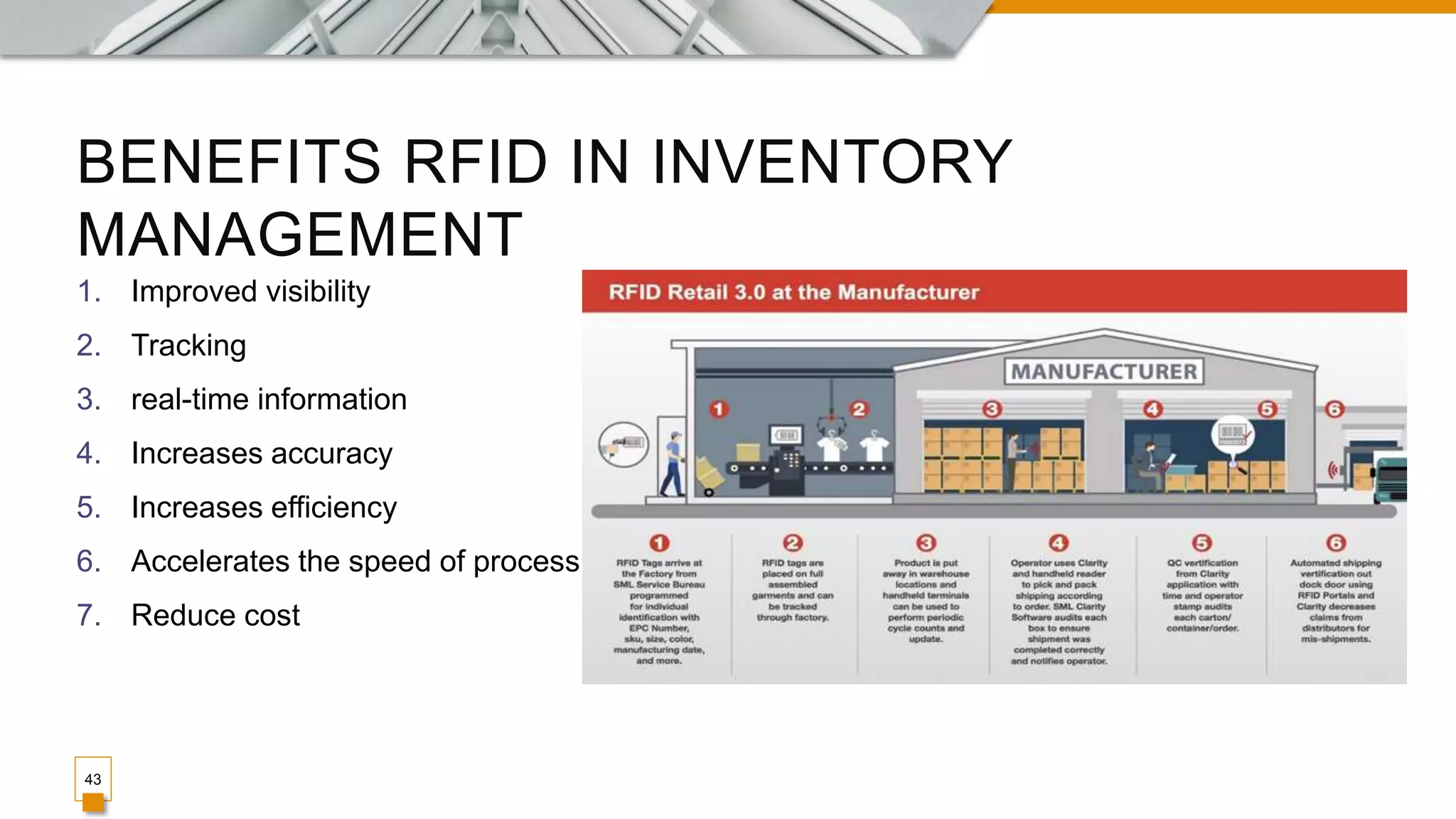

This document discusses key concepts in IoT including sensing, actuation, and RFID. It defines transducers as devices that convert signals between different physical forms like sound, electricity, and motion. Sensors are described as devices that detect physical quantities and output a signal that is converted to human-readable form. Characteristics like accuracy, range, and sensitivity are discussed. Actuators are defined as devices that convert control signals into mechanical actions. Common actuator types include electric, fluid, and manual varieties. RFID technology is introduced as using radio waves to identify objects through tags and readers. Benefits of RFID for inventory management are outlined along with potential future applications.