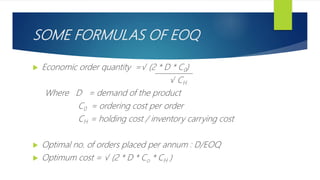

The document discusses economic order quantity (EOQ), which is defined as the optimal order quantity that minimizes total variable costs of ordering and holding inventory. It assumes uniform and constant demand, a constant lead time, no limits on order size, independent ordering costs, and consistent order quantities. Formulas are provided to calculate EOQ using annual demand, ordering cost, and holding cost. An example is worked through to demonstrate calculating EOQ, number of orders, average costs, and total cost for a company that produces bicycles.